Inspria Med can be thermoformed to extreme degrees of stretching and accurate mold surface reproduction, making it suitable for the manufacturing of dental aligners, for example. The clear, transparent sheets made of copolyester can withstand temperatures up to 194°F/90°C and are easy to process, according to the company. The material is suitable for various methods of sterilization, including gamma radiation and ethylene oxide.

Vivak Med is suitable for deep-drawn containers and trays for medical devices and skin contact applications, such as prostheses. The material can be rapidly thermoformed without pre-drying, with low energy consumption, short production cycles, extreme stretching and accurate mold surface reproduction.

Exolon Med is highly impact-resistant and suitable for rigid packaging and the protection of medical. Exolon Med sheets can be thermoformed, cold-curved and machined with ease. They can withstand temperatures up to 248°F/120°C.

All Med-Range products are made of 100 percent virgin material that meets the requirements of ISO 10993 for the biological evaluation of medical devices. The sheets are produced in accordance with good manufacturing practice (GMP). The manufacturing process is subject to constant control by a quality management system that meets the ISO 9001:2015 standard. Processors can thus trace the sheet material down to the raw material — an important basis for further documentation of future end products. www.exolongroup.com.

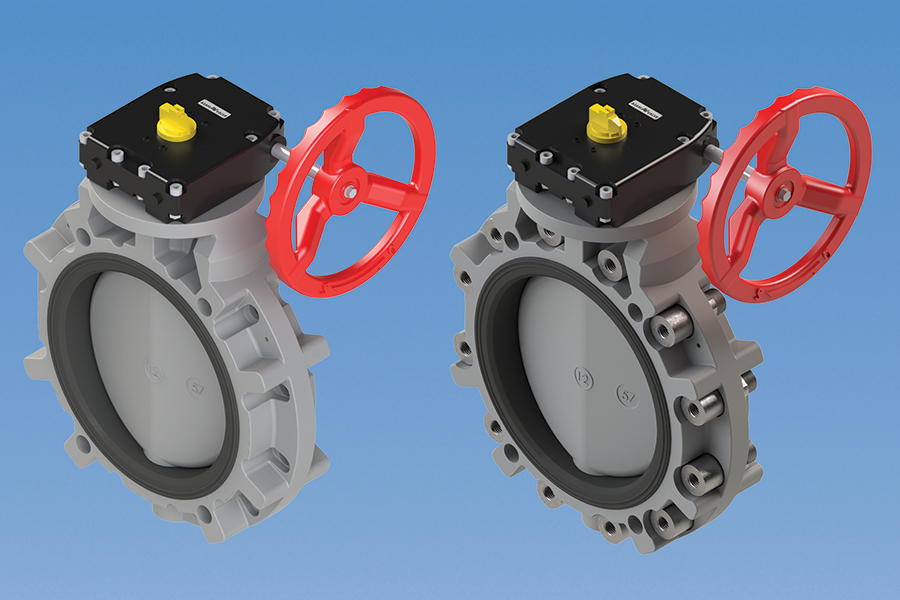

The Type-57P CPVC butterfly valve is available in ANSI wafer style connection or with 316 stainless steel lug inserts in 10″ and 12″ sizes. Both options are offered with a Plasgear™ operator only. Additionally, the Type-57P CPVC can be actuated both electrically and pneumatically, and various manual accessories can be installed.

Asahi/America’s Type-57P CPVC 10″ and 12″ size butterfly valves are suited for chemical processing applications, in facilities such as datacenters, where large diameter CPVC body and disc butterfly valves are required due to elevated water temperatures. All Asahi/America thermoplastic valves come with a three-year warranty. www.asahi-america.com.

Braskem North America Sustainability Director Geoffrey Inch commented on the product launch, “Today’s announcement is another milestone in Braskem’s journey to a carbon neutral circular economy and reinforces our commitment to polypropylene as the PP leader in North America. Not only will Braskem’s new PCR polypropylene grades help our clients meet their commitments for recycled content in FDA food-contact markets, where PCR solutions are limited today, these developments will also keep us on track to reach our goals of providing 300,000 tons of thermoplastic resins and chemicals with recycled content by 2025 and one million tons of thermoplastic resins and chemicals with recycled content by 2030.”

Braskem PCR Polypropylene — Thermoforming grade contains 25 percent post-consumer recycled content and meets the requirements for certain FDA food contact applications, including high temperature packaging. This grade is suited for thermoforming applications that can be used for a variety of applications including food retail and food service trays, coffee lids and several other packaging products.

Braskem PCR Polypropylene — Caps & Closures (C&C) grade contains 25 percent post-consumer recycled content and meets the requirements for certain FDA food contact applications. This grade is suited for injection molded caps and closures in segments such as food and beverage, health, hygiene and cosmetics. www.braskem.com/usa.

Frank Butterfield, vice president of sales and marketing for the window and door division of Kommerling USA commented, “We are excited about the addition of this new color. The trends in today’s market are for darker colors in the exterior use and adding the matte finish black smooth, will enhance our offering. Our color options are designed to be in the harshest of climates and still perform to the Kommerling standard of quality and performance.” www.kommerlingusa.com.

LEXAN CLINIWALL AC6206 sheet, designed for interior wall cladding, received a score of 75 out of 77, and LEXAN CLINIWALL C6206 sheet for interior wall cladding earned a score of 73 out of 77. These awards highlight SABIC’s commitment to enhancing building design and promoting a healthier experience in indoor spaces, including hospitals and industrial and public facilities, through hygienic materials.

Friendly Materials Inspired by PMMT is the result of a three-year research project to identify the healthiest building materials that use non-toxic materials. For instance, LEXAN CLINIWALL engineered thermoplastic panels feature non-halogenated flame retardancy and are volatile organic compound (VOC) duty free. Friendly Materials is an analytical assessment methodology for evaluating and objectively comparing how building materials and systems affect indoor areas and the health of occupants. www.sabic.com/ff.