Table

of

Contents

IAPD Source Guide

See the print edition of this publication for the following Source Guide listings:

- All IAPD Members Geographical Listings

- Plastics Material & Shapes Guide

- Resin & Semi-Finished Plastics Manufacturers

- Equipment & Service Providers

- Plastics Trade Names Directory

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

Wide Variety of 3 & 5 Axis Machining Centers for Plastic and Composite Trimming

Heavy-duty three axis designed for composites, plastic sheets, aluminum, cabinets, wood and nested base panels. Available in either single or dual spindles with optional rotary axis.

Table Sizes: 5’x’5, 5’x10’, 5’x12’, 6’x12’ and 7’x12’

MULTIPURPOSE 63

Large bed axis CNC router with moving bridge & stationary table designed for two and three dimensional machining of large composite parts & three dimensional patterns. Available in either a three or five axis configuration.

Table Sizes: 5’x10’ (1.5m x 3.0m), 5’x20’ (1.5mx6.0m), 5’x40’ (1.5mx12.0m), Table Extensions available up to 100’ (18m)

LFM

Large bed 3 axis CNC router with moving bridge & stationary table designed for two and three dimensional machining of large composite parts & three dimensional patterns.

Table Sizes: 10’x20’, 10’x30’, 10’x45’ additional sizes up to 80’.

MULTIPURPOSE 67

Versatile five axis available with either single or dual moving aluminum tables used for plastic trimming, patterns, molds and non-ferrous metals.

Table Sizes: Single Table – 5’x’5, 5’x10’, 10’x5’, 5’x12’, and 7’x10’ Dual Tables – 5’x5’, 5’x10’ and 5’x12’

MULTIPURPOSE 90

Heavy-duty, high-speed trimming and pattern machining, available in single or dual moving aluminum tables.

Table Sizes: Single Table – 5’x’5, 5’x10’, 10’x5’

MULTIPURPOSE 70

Designed for aerospace and composite applications utilizing large/heavy fixtures.

Table Sizes: 10’x5’, 10’x10’, 10’x15’, 10’X20’

MULTIPURPOSE 77

Heavy-duty, high-speed contained system for the machining of large aerospace and composite materials.

Table Sizes: 5’x10’, 10’x10’, 10’x20’, 10’x30’, 10’X40’ and up in 10’ increments in length

Made in USA

800-533-6901

The Importance of Manufacturers in Our Distribution Supply Chain

IAPD President

anufacturers play a vital role in the world of distribution, serving as the foundation of the supply chain. This is especially true in our performance plastics industry, where the complexities of production, product development and quality control are paramount. For all of us in IAPD, understanding the significance of manufacturers within the distribution network is crucial for ensuring efficiency, innovation and customer satisfaction.

Recently, I have had some lively discussions with a few of our manufacturer members, asking why IAPD is the International Association of Plastics “Distributors” when manufacturers comprise over half of our membership. I explained that the “D” in IAPD is actually “Distribution,” and distribution includes the whole supply chain — from resin, to manufacturer, to distributor, to end user.

Performance Plastics: Powering Modern Society and Changing Lives

IAPD CEO

s we release this year’s Performance Plastics magazine Source Guide, a comprehensive listing of the materials and trade names our member manufacturers produce, we have an opportunity to reflect on the critical role that performance plastics play in modern life. These materials are not just essential components of advanced technology; they are integral to the daily lives of people across the globe. From transportation and healthcare to agriculture and construction, performance plastics are key drivers of progress, innovation and sustainability.

Innovation

Innovation Quality

Quality Worldwide Distribution

Worldwide DistributionConveyor Guide Rails made with King Hy-Pact® in black

Innovation

Innovation Quality

Quality Worldwide Distribution

Worldwide Distribution

Conveyor Guide Rails made with King Hy-Pact® in black

The production process involves collecting UCO and repurposing it upstream to produce certified bio-circular ISCC Plus PP. Braskem has partnered with suppliers in the value chain who convert this bio-circular feedstock into polypropylene, creating a sustainable loop.

WENEW maintains identical properties and performance to traditional PP, making it suitable for food packaging, flexible packaging and consumer goods while allowing it to integrate into existing downstream production and end-of-life recycling processes.

Showcase

Pebax is designed for high performance sportswear, using two block copolymers, polyether and plyamide, to create a durable material with high flexibility, elasticity and strength while remaining extremely lightweight. Compared to alternative materials on the market like EVA or TPU, Pebax has low energy loss, meaning that when the polymer is stretched, it efficiently stores and then returns the same energy when relaxed, giving the wearer’s feet a boost.

Landmark Bipartisan Legislation Addressing America’s Recycling Infrastructure Introduced in U.S. House of Representatives

eptember 19, 2024, in the U.S. House of Representatives, Congressmen Larry Bucshon (R-IN) and Don Davis (D-NC) introduced the Accelerating a Circular Economy for Plastics and Recycling Innovation Act. The landmark legislation is designed to tackle the challenges of plastic waste and improve the innovation of sustainable materials by establishing standards for the nation’s recycling infrastructure.

The bipartisan bill provides a comprehensive framework to transform the plastic lifecycle and seeks to increase efficiencies and provide opportunities for new innovation. The legislation includes three primary components:

EnvironmentalCorner

Eagle Performance Plastics, Inc. Launches Innovative Waste Recycling Initiative

agle Performance Plastics, Inc. has partnered with Convergen Energy to repurpose plastic waste into fuel pellets, marking a major shift in the company’s waste management strategy.

The initiative addresses a long-standing challenge in the plastics industry: the disposal of mixed plastic shavings generated from machining customer parts. These shavings, comprising various plastic types, have traditionally been difficult to recycle due to their mixed composition.

Understanding the Principles and Importance of ISO 14001 in the performance Plastics Industry

n recent years, the term ESG has become a buzzword in the corporate world, influencing investment decisions and corporate strategies globally. ESG stands for environmental, social and governance; representing a framework used to assess an organization’s collective conscientiousness for social and environmental factors. As the focus on sustainability and corporate responsibility grows, understanding ESG is crucial for businesses, investors and consumers alike, particularly in the plastic industry. Integrating ESG principles with ISO 14001, an internationally recognized environmental management standard, provides a robust approach to achieving sustainable practices.

Flat Stock

Sheet Stock

Profile Shapes

Fabrication

3311 Enterprise Road

Fort Wayne, IN 46808

SpecialFocus

The Importance of a Good Processor:

Five reasons WHY plastic STOCK SHAPES MANUFACTURED BY INDUSTRY-LEADING EXTRUsion AND molding companies ARE WORTH PAYING EXTRA FOR

ngineers who work in critical-service industries such as aerospace, medical and semiconductor, will often take great care to specify a particular resin to ensure the quality and performance of a plastic part. Plastic material specifications may include a resin brand and grade number or conformance to an ASTM or ISO standard. Interestingly, this approach to material specifications neglects one of the most important parts of the supply chain: the plastic processor who converts the resin pellets into stock shapes. The expertise of the processor, the quality of the extrusion or molding machinery and the manufacturing methods can result in significant variation in the fabrication characteristics of plastic stock shapes and the performance of plastic parts.

Plastic sheet, rod, tube and film materials manufactured by industry-leading molders and extruders tend to be a bit more expensive compared with materials produced by lower quality processors who cut corners. The purpose of this article is to discuss five reasons why it’s worth paying more for plastic stock shapes produced by leading extrusion and molding companies.

People &

Places

Kearley

Kreinces

Curbell Plastics, Inc. Supports Local Education with Sign Material for The Teacher’s Desk

he Western New York location of Curbell Plastics, Inc. brought visibility to an organization supporting education through the donation of aluminum composite material (ACM) to The Teacher’s Desk in Buffalo, NY, USA.

Curbell Plastics, Inc.’s ACM donation was used to create large, vibrant exterior signage for the organization’s facility, improving its visibility for teachers and other visitors coming in for school supplies. This material donation supports Teacher’s Desk’s efforts to alleviate financial burdens on teachers and enhance the educational experience for countless students in the Buffalo area.

“We are pleased to support The Teacher’s Desk in their mission to provide essential resources to teachers and students in local schools,” said Jeff Burke, Regional Director at Curbell Plastics. “By donating these ACM sheet materials, we are contributing to an organization dedicated to providing an inspiring and supportive environment for both educators and students.”

REP BUSINESS

Exchange

Fabrication

SERVICES SHOWCASE

Fabrication Services Showcase contains paid listings of companies with fabrication services, products and machinery that cater to the performance plastics distribution industry. IAPD does not endorse nor make recommendations in regard to the companies supplying their services. For details and pricing information to include your company in this Fabrication Services Showcase, contact Dave Blackhurst, IAPD’s Sales Executive, at (913) 345-1005 or email dblackhurst@iapd.org.

CNC Equipment

Sawing, trimming, drilling, polishing, measuring or 3D processing — no matter what techniques are involved, Stiles has the CNC technology to get it done. Their machining solutions can be custom-configured to your specific needs. From productivity and high precision, to energy and material savings, Stiles provides proven CNC options for plastics processing. For more information, contact info@stilesmachinery.com or visit www.stilesmachinery.com.

Vortex Tool Company, Inc. designs and manufactures a wide variety of standard and custom high-performance router and insert cutting tools for the woodworking and plastics industries, and provides retipping and sharpening services for all makes and models. www.vortextool.com, phone (800) 355-7708.

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Artek, Inc. • (800) 762–6808 • www.artek–inc.com

Champion Fiberglass • (281) 655–8900 • www.championfiberglass.com

Ensinger • (800) 243–3221 • www.ensingerplastics.com

Fluoro–Plastics • (800) 262–1910 • www.fluoro–plastics.com

Gallina USA, LLC • (888) 463–3342 • www.gallinausa.com

Hudson Extrusions, Inc. • (800) 837–6015 • www.hudsonextrusions.com

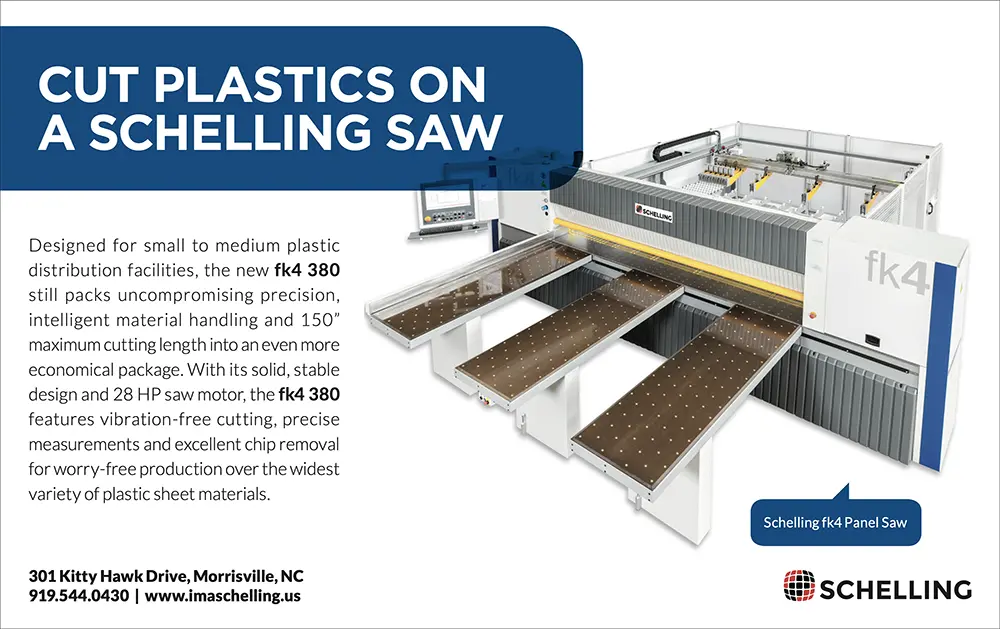

IMA Schelling Group, USA • (919) 544–0430 • www.imaschelling.us

King Plastic Corporation • (800) 780–5502 • www.kingplastic.com

Mitsubishi Chemical Group • (610) 320–6600 • www.mcam.com

NewAge Performance Products • (215) 526-2300 • www.newageindustries.com

Palram Americas • (800) 999–9459 • www.palramamericas.com

Petro Extrusion Technologies, Inc. • (800) 229–3338 • www.petroextrusion.com

Pexco LLC – Corporate Office • (770) 343-4095 • www.pexco.com

PLASKOLITE • (800) 848–9124 • www.plaskolite.com

POLYVANTIS • (812) 831-7000 • www.polyvantis.com

Rowmark LLC • (800) 243–3339 • www.rowmark.com

SIMONA AMERICA Group • (866) 501-2992 • www.simona-america.com

Spartech • (800) 677–4338 • www.spartech.com

Thermwood Corporation • (800) 533–6901 • www.thermwood.com

Wegener Welding, LLC • (800) 647–3061 • www.wegenerwelding.com

BoardofDirectors

Michelle Betz • Alro Plastics • Jackson, Michigan, USA

Jeff Burke • Curbell Plastics, Inc. • Orchard Park, New York, USA

Katie Clapp • A&C Plastics, Inc.• Houston, Texas, USA

Chris Corona, Executive Committee • CartierWilson LLC • Solon, Ohio, USA

Bryan Davis • Ensinger • Washington, Pennsylvania, USA

Peter DelGado, President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Kevin Duffy • VYCOM – A PLASKOLITE COMPANY • Scranton, Pennsylvania, USA

Bob Healy • Mitsubishi Chemical Group • Reading, Pennsylvania, USA

Hayden Hess, Executive Committee • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Advanced Materials • Sacramento, California, USA

Jim Richards, Vice President • PLASKOLITE • Columbus, Ohio, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Director of Marketing & Content

Erin Smith

esmith@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Keith Hechtel • Curbell Plastics, Inc. • Orchard Park, New York, USA.

Jeff Mikitka • Mitsubishi Chemical Group • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Publishing

Headquarters

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Director of Marketing & Content

Erin Smith

esmith@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Editorial Committee

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Keith Hechtel • Curbell Plastics, Inc. • Orchard Park, New York, USA.

Jeff Mikitka • Mitsubishi Chemical Group • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Thanks for reading our October/November 2024 issue!