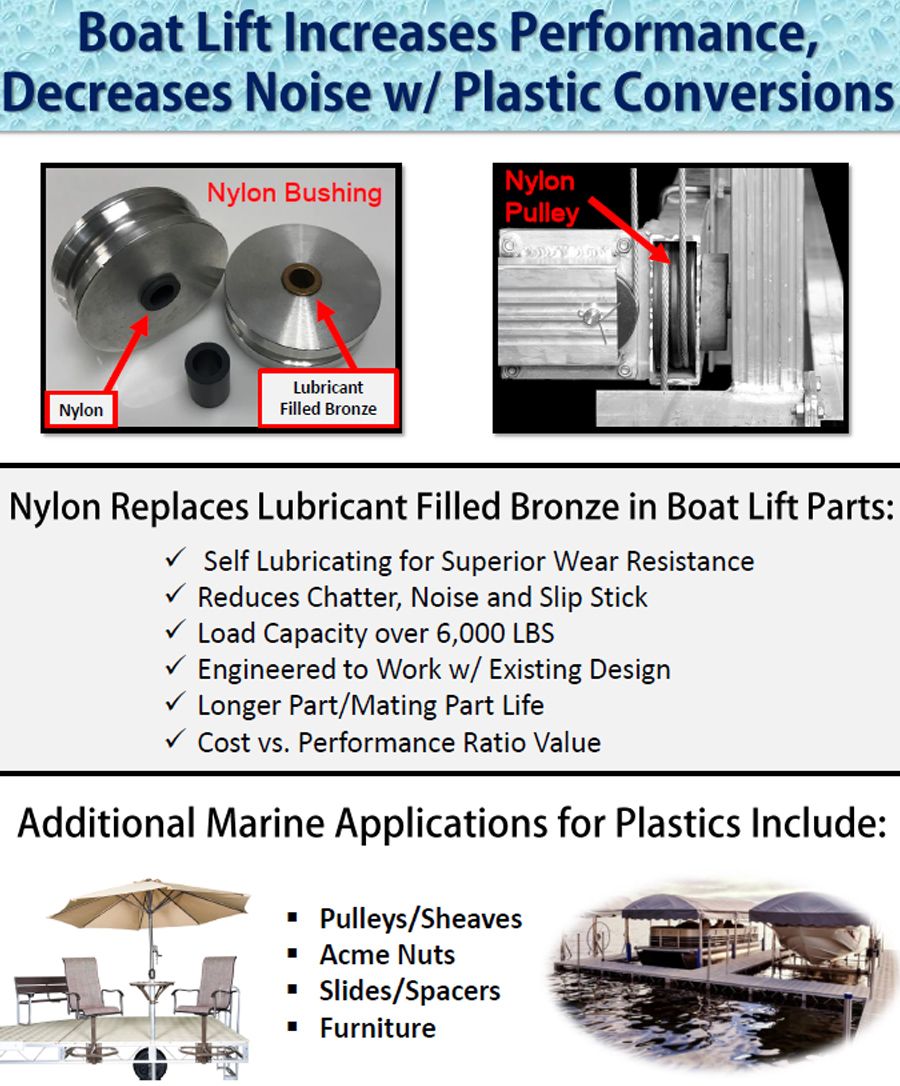

An upper Midwest manufacturer of maintenance-free boat, pontoon and personal watercraft docks and lifts looked for an alternative solution because neither aluminum pulleys nor injection molded pulleys were giving them ideal results. Both the aluminum and injection-molded pulleys (which require bronze or alternative metal bushings) were causing squealing noises and “stick-and-slip” motion during normal operation. This result is common with metal materials since metallic bushings have a less desirable coefficient of friction (COF) for this application, which causes premature wear and stress on the entire lift.

The performance plastics solution involved sheaves prototypes machined from solid nylon rods that needed no metallic bushing. They also deployed rigorous testing to prove the solution was able to stand up to the customer’s configuration. Through comparison with the injection-molded and aluminum alternatives, all agreed that the machined nylon sheaves were a far superior solution that provided a viable alternative to injection-molded and machined metal components.