ondit has a rich and storied history in the world of exhibit fabrication, going back to 1945. The company offers a full range of design and fabrication services, as well as rental exhibit services, from its headquarters in Denver, CO, USA and satellite location in Chicago, IL, USA.

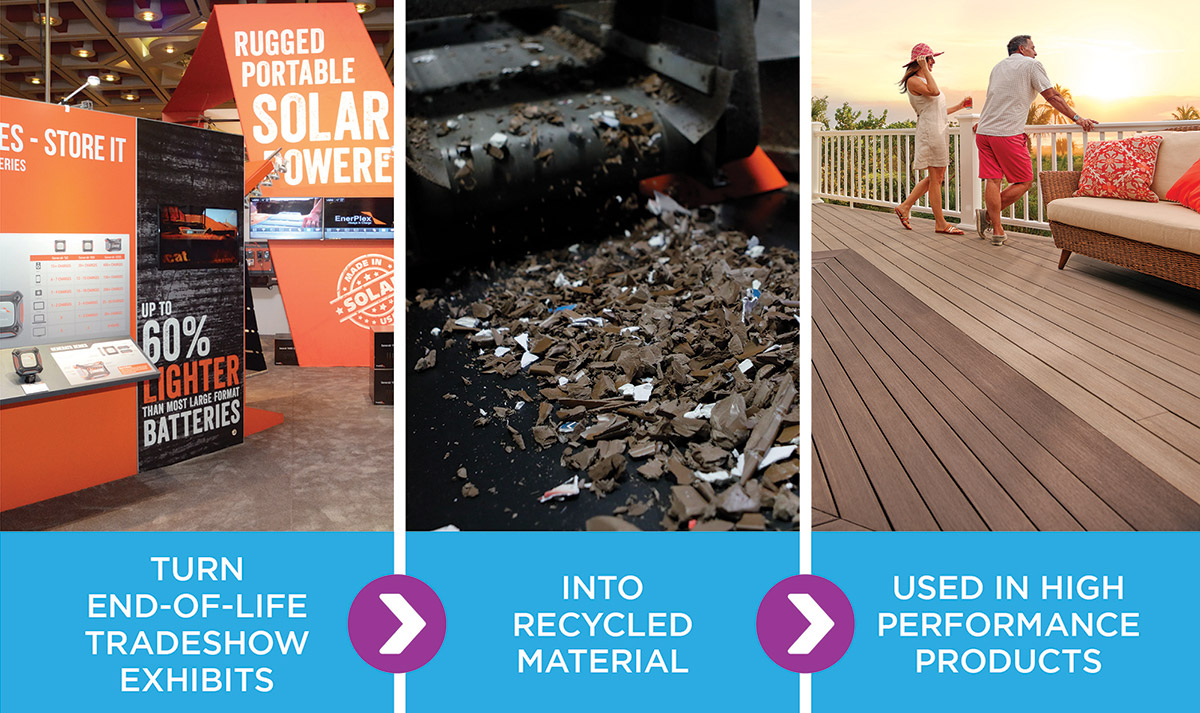

Among the various materials used to produce custom tradeshow exhibits, the company uses polyvinyl chloride (PVC) and acrylics in a wide variety of applications such as three-dimensional graphics letters and logos, infill panels for its rental wall systems, display cases and decorative finishes. Using a UV flatbed printer, the fabrication team also prints to full 4′ x 8′ PVC sheets, as well as adds printed vinyl laminate graphics depending on the project.

MacDonald learned about Vycom’s novel PVC Recycling Program while consulting with Mike Sherrod, market development manager, graphics and sustainability. In this model, Vycom takes back and recycles printed and unprinted PVC sheets, as well as scraps and drops from finishing and fabricating. “The key part of the program is that Vycom accepts the PVC and acrylic sheets with Velcro, and takes care of removing it at their facilities,” said MacDonald. “Vycom’s innovative process allows us to recycle all panels without peeling old graphics, Velcro, etc., before disposal. In addition to greater recycling efficiency, this also allows for a larger percentage of acrylics and PVC to be recycled.”

Condit is just getting started with the Vycom PVC Recycling Program and has conducted training programs for team members to better understand the recycling pipeline for PVC. It has also placed several custom recycling bins around its manufacturing floor and warehouse to accommodate these specialized materials.