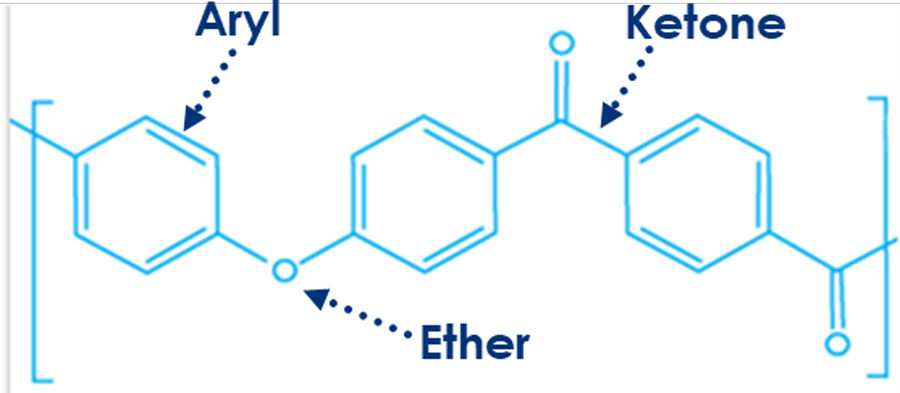

olyaryletherketones (PAEKs) are a family of high-performance thermoplastics originally developed in the 1960s by DuPont for the Apollo space program. Since this creation, one-such PAEK — polyetherketoneketone (PEKK) — has been widely used in the aerospace and defense industries. PEKK’s outstanding high temperature performance, chemical resistance and flame, smoke and toxicity (FST) profile make it a perfect candidate for multiple applications within the transportation industry.

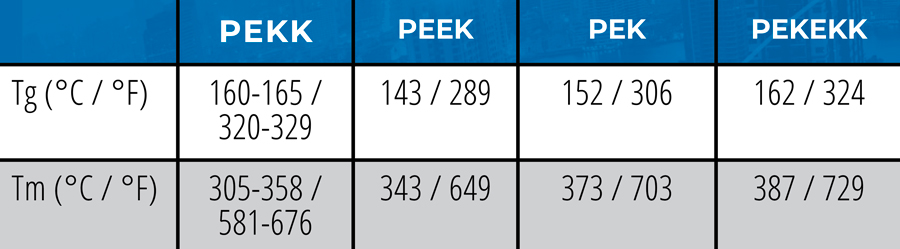

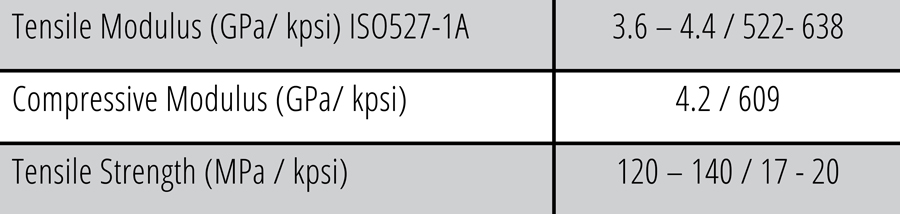

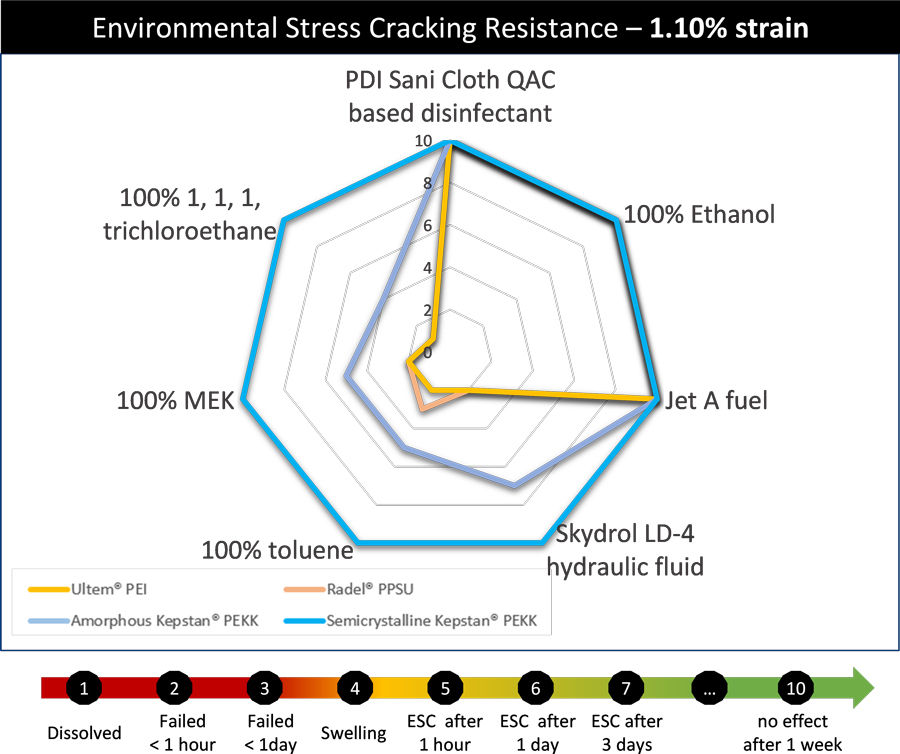

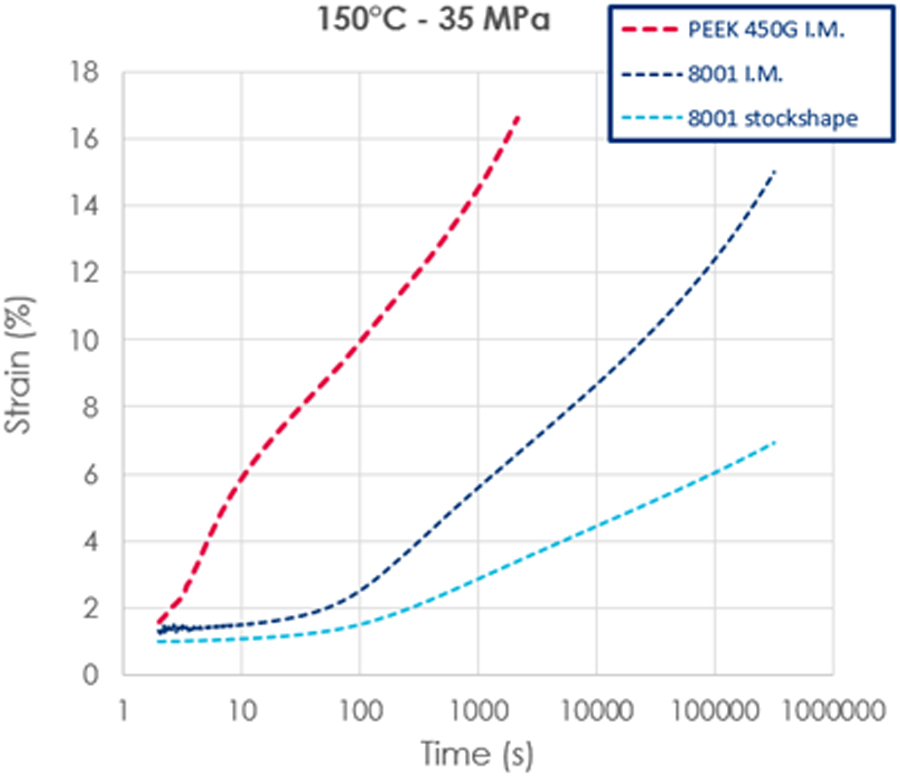

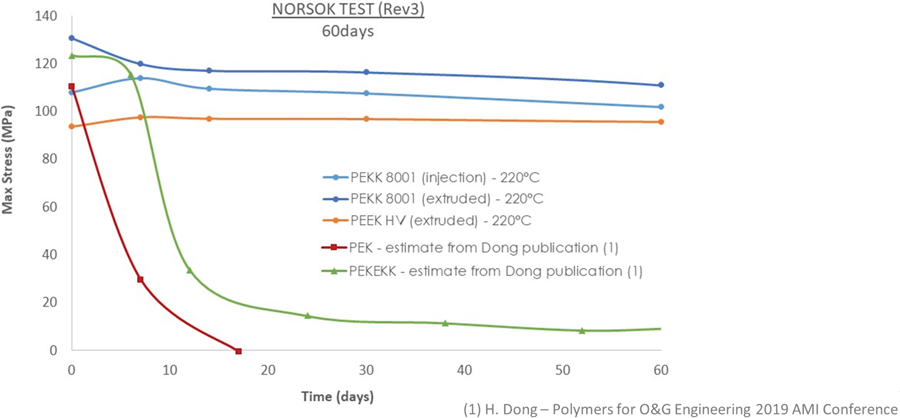

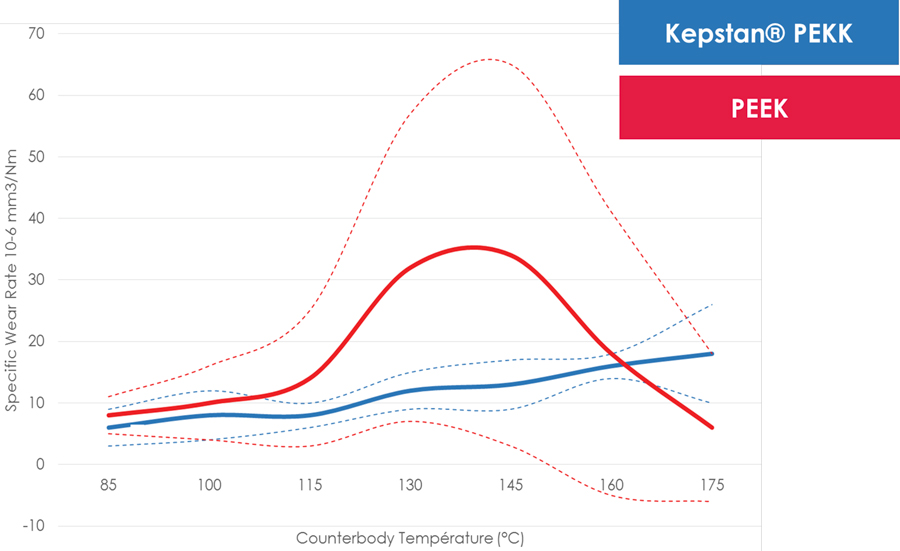

PEKK offers many advantages over other PAEK polymers. PEKK exhibits higher strength and modulus compared to PEEK due to its ketone/ether ratio of 2:1 (compared to 1:2 for PEEK). This higher ketone/ether ratio also increases thermal properties of the material, enabling PEKK to be used in applications with higher continuous use temperature requirements. These advantages allow PEKK to compete on a property basis with other high temperature PAEK materials such as polyetherketone (PEK) and polyetherketonetherketoneketone (PEKEKK) while remaining lower cost and providing more processing options and wider processing windows (tables 1 and 2).

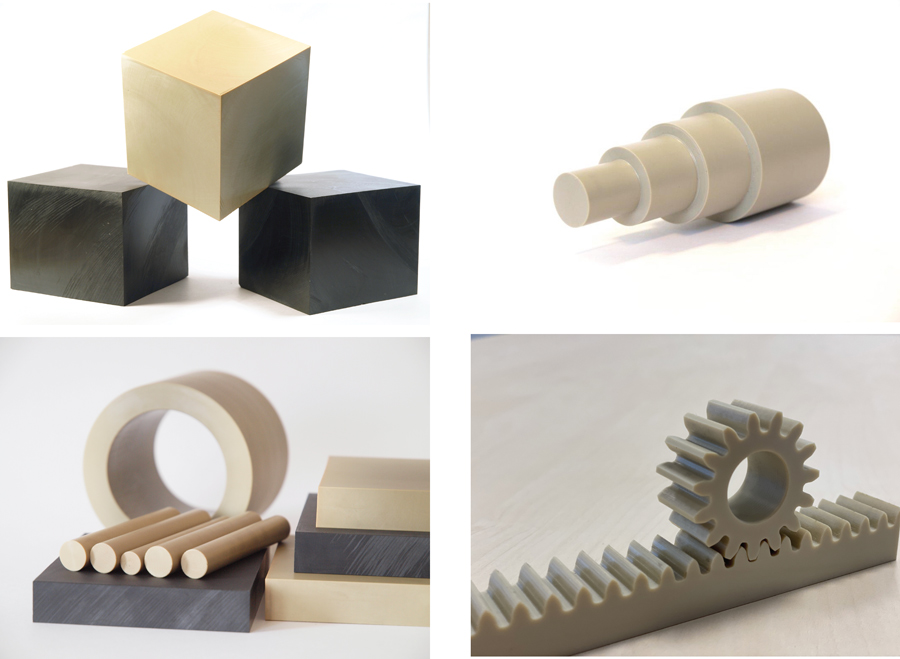

Materials with low dielectric constants are becoming increasingly attractive as electric vehicles go to higher power and voltages. Increased partial discharge induction voltages (PDIV) are required to prevent cross-talk amongst electrical components. Both machined components and insulation for magnet wire can benefit from the low dielectric constant of PEKK (as low as 2.6) and its ability to outperform other PAEKs by better maintaining this lower dielectric constant at the elevated temperatures reached during operation. This same insulative performance makes PEKK an excellent candidate for stock shape applications in the electronics and semiconductors markets, including RFI/EMI connectors, wafer/electronic carriers or trays and semiconductor test sockets.

All the data provided in the article is based on studies by Arkema.

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of the information referred to herein are beyond our control, Arkema expressly disclaims any and all liability as to any results obtained or arising from any reliance on such information; NO WARRANTY OF FITNESS FOR ANY PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY, OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED, IS MADE CONCERNING THE INFORMATION PROVIDED HEREIN. The user should thoroughly test any application before commercialization. Nothing contained herein constitutes a license to practice under any patent and it should not be construed as an inducement to infringe any patent, and the user is advised to take appropriate steps to be sure that any proposed action will not result in patent infringement.