GEHR Plastics, Inc. announced ECO-GEHR PLA-HI® sheets based on renewable raw materials consisting of 90 percent PLA. They are produced — as all GEHR products — CO2 neutral according GHG Protocol Scope 1+2. The sheets have high impact strength and are suitable for demanding applications. Mechanical processing of the sheets is easily possible, as are post-processing techniques such as deep drawing, printing, gluing, sawing, drilling and punching. The sheets are available in thicknesses of 2, 3 and 4 mm; width: 1000 mm; length: 2000 mm. The sheets are in stock in natural/translucent color but can also be dyed. www.gehrplastics.com.

*Corresponds to 1,3 lbs CO2 (emission of greenhouse gas) for the production of 1 lbs ECO-GEHR PLA-HI® sheets in comparison to ABS: 5,5 lbs CO2.

Curbell Plastics, Inc. announced new additions to their orthotics and prosthetics suite of products.

Super-EZ™ Release Spray — This eco-friendly formulated product is made for orthotics and prosthetics fabricators. The proprietary water-based Super-EZ Release Spray is intended for use with carved foam molds to make plastic pulls easy without having to pull a sacrificial layer or use an expensive stockinette. Formulated with the environment in mind, it is made from natural plant-based resources, is non-toxic and volatile organic compounds (VOC)- and silicone-free. It is applied directly onto the stockinette covered mold using a standard trigger spray bottle. Super-EZ Release Spray is available in one-gallon jugs.

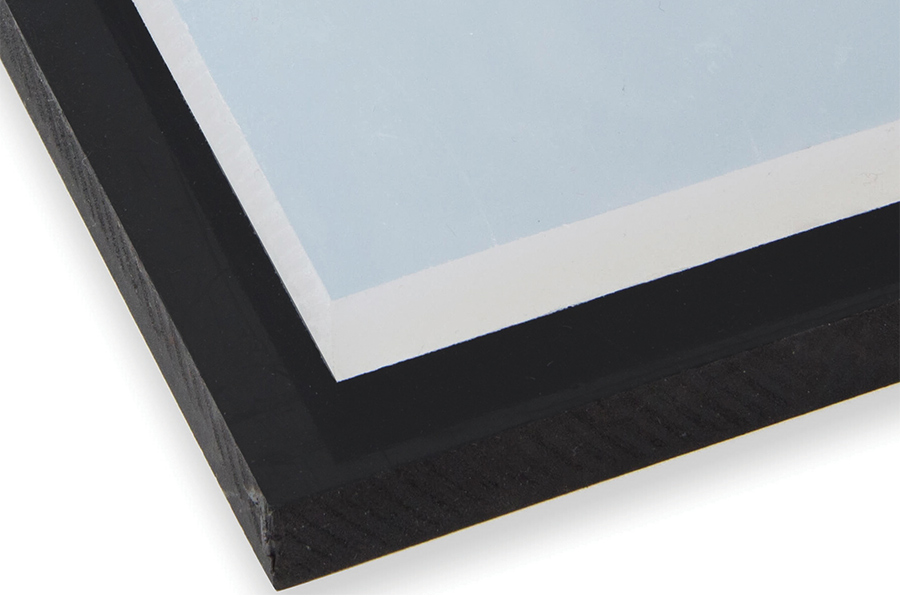

OP-TEK® Flex Comfort Black — Curbell’s OP-TEK Flex Comfort material is now available in both black and white sheet. OP-TEK Flex Comfort Black is silicone-free, which improves wall thickness consistency during fabrication and has 20 percent greater melt strength compared with silicone-filled flexible inner liner materials. It is internally lubricated for decreased friction, making donning and doffing more comfortable for the patient. The new OP-TEK Flex Comfort Black sheet is available in 3/8″ and 3/16″ thicknesses.

“Bringing together the performance of plastic materials and fabrication capabilities, Curbell O&P will continue our focus on developing and releasing innovative products,” said Jeff Wilson, senior business development manager for Curbell O&P. “Our desire to bring new products to the O&P market stems from our mission to help O&P professionals and the patients they serve.” www.curbellplastics.com.

Asahi/America, Inc. has expanded its building information modeling (BIM) library on its website to include three additional product lines:

- PP-Pure® pigmented PP high purity piping system

- Super Proline® chemical grade PVDF piping system

- PolyPure® natural PP high purity piping system

The library also contains CAD files for the company’s Air-Pro® compressed air piping system, Asahitec™ PP-RCT commercial HVAC and plumbing piping systems, Proline® single wall industrial piping system, Purad® ultra high purity PVDF piping system, as well as manual valves.

Engineers, estimators and designers can download CAD files through the online catalog at http://cad.asahi-america.com.

Users can access the files by choosing the desired part, file type and then download, print or email the files. The interface supports 32 formats. BIM software platforms include Revit®, AutoCAD® MEP and CADmep™. Supported CAD software platforms include AutoCAD®, Pro/ENGINEER®, Catia®, SolidWorks® and Solid Edge®.

Asahi/America valves, actuators and piping systems are used in a variety of applications and industries including chemical processing, water and wastewater treatment, commercial plumbing, pharmaceutical and semiconductor manufacturing, aquariums, mining, landfill and oil and gas. www.asahi-america.com.

AGRU America, Inc. has received FM Approvals’ Standard 1613 for its AGRULINE HDPE pipe fittings. FM Approved pipes and fittings are rigorously tested to meet certain stands of quality, technical integrity and performance in support of commercial and industrial facilities. AGRULINE HDPE fittings with FM Approval help certify that these products will perform under the toughest conditions.

“AGRU America has a long, rich history of manufacturing precision-engineered pipe and fittings,” said Melissa Grace, vice president of AGRULINE. “To receive FM Approval certification of our AGRULINE fittings is further confirmation of our commitment to delivering the highest quality products on the market.”

AGRULINE high-density polyethylene (HDPE) pipe fittings are manufactured from the newest generation of PPI- and NSF-listed materials, meeting a range of standards including ASTM D3261, ASTM D2513, NSF 61 and AWWA C901 and C906. AGRULINE HDPE pipe fittings offer superior flow characteristics while retaining the lightweight and flexible properties that have made HDPE products popular in construction.

“AGRULINE HDPE pipe fittings have been used to create solutions in a wide array of applications,” said Grace. Applications include wastewater, potable water, gas distribution, mining, landfill, irrigation and aquaculture. “With FM Approval, AGRU can confidently broaden its end-use applications to the industrial market.”

FM Approvals is an international leader in third-party testing and certification services backed by scientific research and over a century of experience. Its FM APPROVED mark on HDPE pipe and fittings indicates reliable product performance for use in underground fire protection systems.

“We are proud of our AGRULINE team’s hard work in earning FM Approval,” said Robert Johnson, CEO of AGRU America, Inc., “By offering FM 1613 Approved AGRULINE fittings, AGRU is now able to deliver products that have proven reliability for use as underground fire protection lines and more.” www.agruamerica.com.

GF Piping Systems has expanded its full-bore, magnetic FlowtraMag® Meter product line to include two new pipe sizes in 1.5″ and 3″. This complements the existing 1″, 2″ and 4″ sizes to bring the total offering to five sizes under its new 2581 Model Number. A simplified design has been incorporated along with EPDM seals for greater chemical compatibility and application versatility.

The flow meter’s PVC body with standard titanium and optional Hastelloy® C electrodes is designed specifically for high accuracy flow measurement in short pipe runs. High accuracy is achieved for these problematic runs with a modified sensor design that has shorter inlet and outlet pipe length requirements and certified factory calibration. The Hastelloy C electrode expands its chemical compatibility for other media not suited for titanium.

All thermoplastic body construction provides corrosion resistance for long, maintenance-free service life. Available in PVC Schedule 80, the FlowtraMag is two to three times lighter in weight compared to traditional metal magmeters on the market. The unit also offers accuracy of ±1 percent of reading and repeatability of ±0.5 percent.

Streamlined monitoring and added versatility is provided via the meter’s broad communications capabilities across multiple platforms. These include digital (S3L), frequency and analog 4 to 20 mA (passive or active). Visual LED indicators make sensor status clear and easy to read. The 2581 can connect to union ends in sizes 2″ or less, and flanges for 3″ and 4″.

Users can configure and calibrate the 2581 to the parameters required for their system using the GF Configuration Tool Bluetooth® App. After customizing parameters for low flow cut-off and span, the 4 to 20 mA output users can then monitor the 2581 on their Android or iOS device.

The new flow meter can be used in a wide range of applications and industries. Applications include water treatment skids, batch processing, chemical processing and transport, fluid dispensing, water distribution, reverse osmosis, liquid delivery systems, clarified effluent, metal recovery and landfill leachate, as well as many more.

The 2581 features CE, UL, CUL Recognized Component and is RoHS compliant. It is manufactured under ISO 9001 for quality, ISO 14001 for environmental management and OHSAS 18001 for occupational health and safety. It also complies with Part 15 of FCC rules. www.gfps.com.