of

Involvement

2023-2024 IAPD

Membership Directory

Best Practices

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

IAPD President

fter returning from another successful IAPD Leadership Development Conference (LDC) in beautiful Columbus, OH, USA, I can’t help but reflect on the people, progress and possibilities of IAPD.

Many thanks to PLASKOLITE for hosting IAPD in its hometown and opening their awesome, thought-provoking corporate headquarters for a reception and tours. They really went above and beyond with all the great activities they sponsored to make our time in Columbus memorable.

The LDC committee meetings were successful and the keynote speakers were enjoyable. The association volunteer leaders brought an energy and excitement to the week that is indescribable.

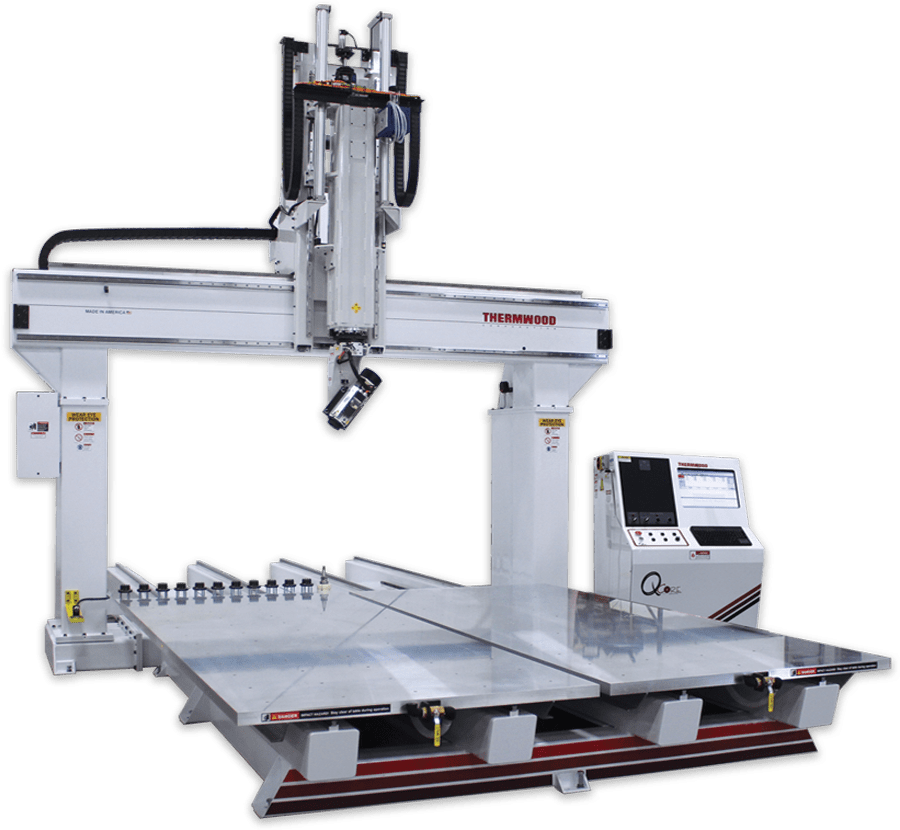

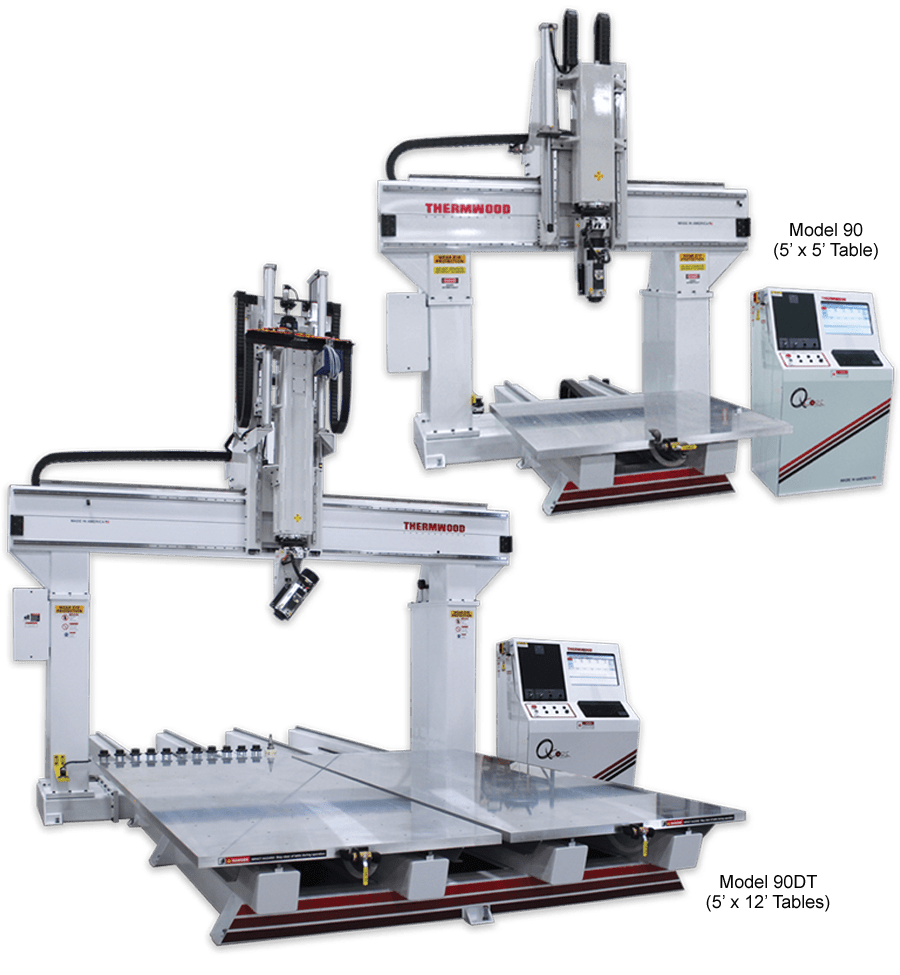

Thermwood Model 90

Heavy Duty 5 Axis CNC for

Three-Dimensional Applications

(5’ x 5’ Table)

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

(5’ x 12’ Tables)

800-533-6901

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

800-533-6901

The Power of a Trade Association

IAPD CEO

n the dynamic and competitive world of business, companies need to explore every avenue available to gain a competitive edge. One powerful strategy that often goes underutilized is joining a trade association and actively participating in industry conventions. These platforms offer a plethora of benefits that can significantly impact a company’s growth and success.

While paying industry association membership dues is a necessary financial commitment, it should not be seen as the sole requirement to reap the full benefits of association membership. Active engagement with industry associations is crucial for businesses to unlock the true value they offer.

Performance plastics companies should not only join to retain membership in IAPD, but engage in the association. At a bare minimum, attend the conventions and leverage the opportunities they offer.

Flat Stock

Sheet Stock

Profile Shapes

Fabrication

3311 Enterprise Road

Fort Wayne, IN 46808

Articles reporting on plastic products are prepared from information furnished by members of the IAPD and non-member magazine advertisers. The information provided is deemed reliable but is not verified. It should not be assumed that the publisher has reviewed or tested any of the products. For more information, contact companies by visiting their websites.

International Space Station Expedition 42 Commander Barry “Butch” Willmore shows off a ratchet wrench made with a 3D printer on the International Space Station.

Redwire Space, NASA advance in-space manufacturing for journeys to the moon, mars and beyond

The smart choice for

many high abuse

application

Available in colors: Black and White

The smart choice for many high abuse application

Available in colors: Black and White

ACRYLITE® Resist multi-skin was used to create giant illuminated letters for the focal point of the stage design for Giacomo Puccini’s opera, “Tosca” at the Halle Opera House in Halle, Germany. The letters spell out “ART” as a stylistic device selected by the opera’s stage designers to put a contemporary perspective on the 1899 opera.

“Normally, Giacomo Puccini’s ‘Tosca’ is a stringently written detective story which takes place at the beginning of the 19th century in Rome,” explained Stage Designer Wolf Gutjahr. “In Halle, we wanted to put the spotlight on the inner states of the people above all else.”

The original settings, which include the interior of a church, a police station and the Castel Sant’Angelo in Rome, were not suited for this purpose. “The main figures are artists who have become caught up in the political system. So, the stage design is intended to display the conflict between politics and art and how we deal with it,” explains Gutjahr.

DEI+BCorner

DEI

Article two in the DEI+B series by the IAPD Diversity Equity and Inclusion Task Force

ecruiting top talent is an essential priority for many organizations. In recent years, there has been a growing recognition of the importance of diversity, equity and inclusion (DEI) principles in the hiring process. To recruit qualified and diverse talent using DEI principles, organizations can begin by identifying and addressing any biases or barriers in their recruitment process that may prevent underrepresented groups (defined as racially or ethnically minoritized populations such as Black, African American, Hispanic, Latino or Indigenous, as well as other realms such as gender minorities including women, nonbinary and neurodivergent populations) from applying or being considered for positions. By actively practicing or embodying DEI principles in their recruiting process, organizations can attract a larger pool of talented candidates and build a more diverse and inclusive workplace.

Prerecruitment efforts

The first step in DEI implementation begins before recruiting starts. Revisiting job descriptions to ensure they are inclusive and free of discriminatory language is essential when recruiting diverse talent. Without intending to, job descriptions can exclude different groups of people based on the words or phrases used. While most know not to use gendered pronouns in job descriptions, gender-coded words can make candidates assume the role is meant for the opposite gender, even if they meet the listed qualifications. For example, some female gender-coded words are “sensitive, support, collaborate, nurture and trust.” Some male gender-coded words are “aggressive, driven, assertive, outspoken and independent.” Other descriptions, such as “fast-paced environments” or “varying work schedules,” might be perceived as a barrier for individuals who are also caregivers and have family commitments.

What is ESG?

ave you heard about ESG in the news, from investors or at work? Maybe customers are asking you to disclose environmental, sustainability and social data. So, what is all this stuff anyway?

In this article we will explore:

- What is ESG and its three pillars?

- Where did the ESG concept originate?

- What are the potential impacts to my business?

- Lastly, we will touch on five steps for you to explore and get started on your ESG journey.

McDaniel has been with Asahi/America, Inc. for over two years as a business development manager for valve and actuation products. During his time at Asahi/America, Inc., he was instrumental in leading technical training and development of the company’s actuation program, including the latest Series 19 actuator product launch.

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Artek, Inc • (800) 762-6808 • www.artek-inc.com

Champion Fiberglass • (281) 655-8900 • www.championfiberglass.com

Ensinger • (800) 243-3221 • www.ensingerplastics.com

Fluoro-Plastics, Inc. • (800) 262-1910 • www.fluoro-plastics.com

GEM Plastics • (706) 779-7791 • www.gemplastics.com

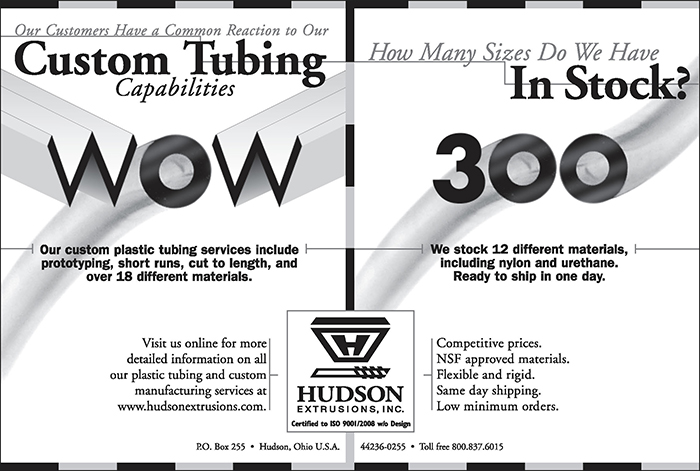

Hudson Extrusions, Inc. • (800) 837-6015 • www.hudsonextrusions.com

King Plastic Corporation • (800) 780-5502 • www.kingplastic.com

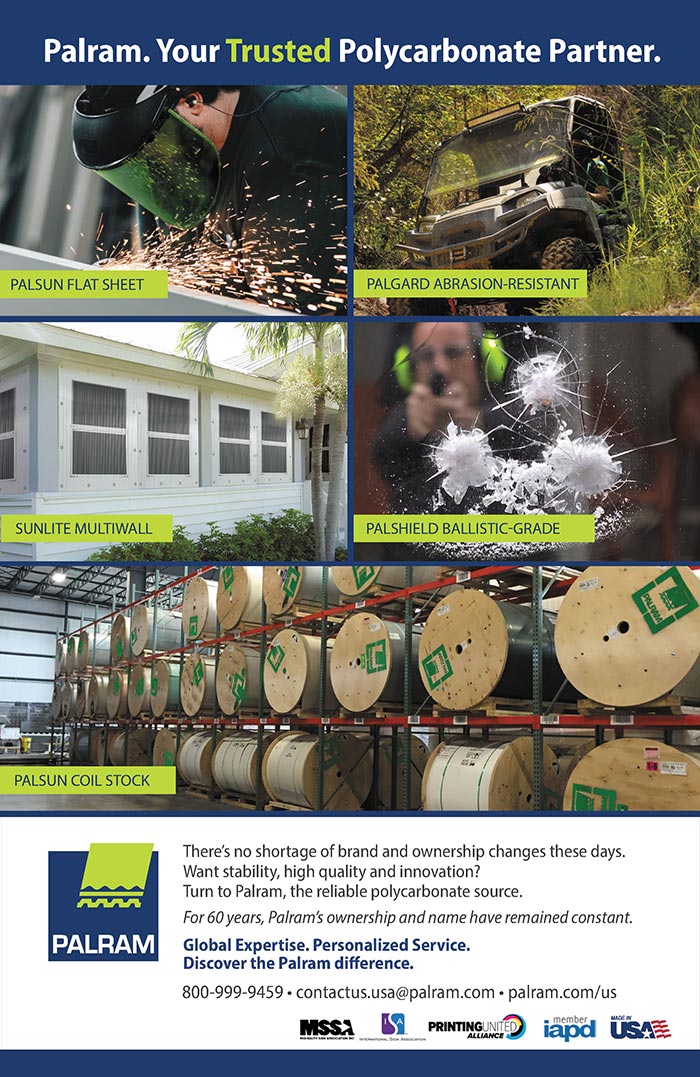

Palram Americas, Inc. • (800) 999-9459 • www.palramamericas.com

Petro Extrusion Technologies, Inc. • (800) 229-3338 • www.petroextrusions.com

PLASKOLITE • (800) 848-912 • www.plaskolite.com

Polymer Industries • (877) 765-9637 • www.polymerindustries.com

Rowmark LLC • (877) 769-6275 • www.rowmark.com

Schelling America, Inc. • (919) 544-0430 • www.imaschelling.us

Thermwood Corporation • (800) 533-6901 • www.thermwood.com

Wegener Welding, LLC • (800) 647-3061 • www.wegenerwelding.com

BoardofDirectors

Bill Barth, Executive Committee • Piedmont Plastics • Charlotte, North Carolina, USA

Karen Brock-Amoah • SIMONA Boltaron • Newcomerstown, Ohio, USA

Jeff Burke • Curbell Plastics, Inc. • Orchard Park, New York, USA

Chris Corona • CariterWilson LLC • Solon, Ohio, USA

Peter DelGado, Vice President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Dale Delmage • Redwood Plastics and Rubber • Langley, BC, Canada

Stephen Garmon • Primex Plastics Corporation • Richmond, Indiana, USA

Hayden Hess • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Plastics • Sacramento, California, USA

Richard Miller • Braskem • Philadelphia, Pennsylvania, USA

Michael Mraz • Alro Plastics • Jackson, Michigan, USA

Deborah Ragsdale, President • Polymer Industries • Henagar, Alabama, USA

Jim Richards, Executive Committee • PLASKOLITE • Columbus, Ohio, USA

Drew Schwartz, Executive Committee • Colorado Plastic Products • Louisville, Colorado, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE

savery@iapd.org

Editor in Chief

Kailee Canty

kcanty@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Junior Copywriter & Editor

Sara Marquardt

smarquardt@iapd.org

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Publishing

Headquarters

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE

savery@iapd.org

Editor in Chief

Kailee Canty

kcanty@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Junior Copywriter & Editor

Sara Marquardt

smarquardt@iapd.org

Editorial Committee

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Thanks for reading our June/July 2023 issue!