uckland, New Zealand is experiencing its worst drought in 25 years. With only half of the typical rainfall and a dry six months in the forecast, officials enacted tough water restrictions in June 2020. In the midst of this crisis, a bottling company came to IAPD distributor member Supply Services Ltd. with a problem: They were consuming 360,000 liters of water (approximately 95,000 gallons) per year lubricating the OEM bushes and lifting rollers in just one of their bottle filling machines. Under pressure from the local council to cut their water consumption, and additional penalties for exceeding their water allocation, this customer was looking for a simple solution to cut their water consumption drastically.

Mark Brown, Supply Services Ltd.’s technical manager of performance plastics, realized that this customer could reduce their water consumption with the implementation of high performance engineering plastics and composite materials. The high performance plastics would let this customer remove the use of water from this operation and become completely dry running.

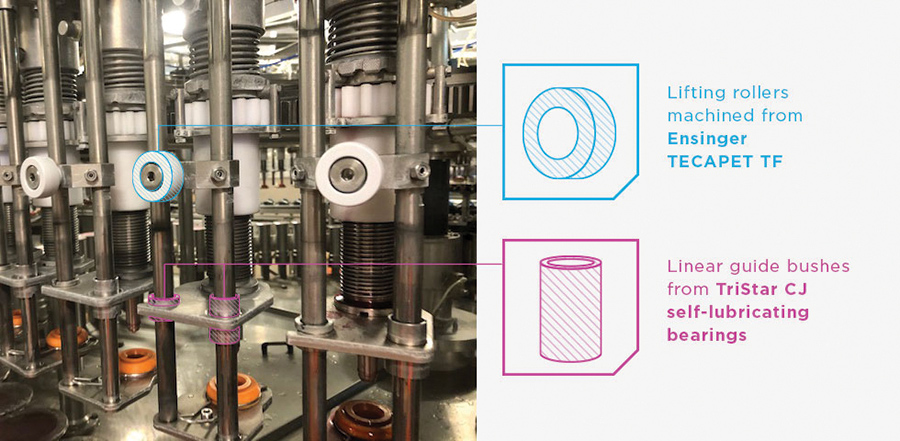

Two high performance materials were required to achieve the dry running of this bottling line: Ensinger TECAPET TF for the lifting cam rollers and TriStar Composite Journal (CJ’s) Bearings for the linear guide bushes. The team designed the finished parts, which were then CNC machined ready for installation at the customer’s site.

TriStar CJ’s bushes were selected because the bushes had to be thin walled and required a super low coefficient of friction with no additional lubrication. The bushes selected are dimensionally stable in fluids and temperatures from -320°F/-195°C to 300°F/149°C, chemically resistant and are self-lubricating. This was the appropriate bearing choice for nonlubricated, high load/low speed applications.

“This customer story is just one example of how performance plastics are having a positive environmental impact,” said Brown. “Water scarcity is causing everyone to be mindful of their usage and conserve when we can. The added benefit for this customer is that these changes will save them money year on year. Plus, because the performance plastics used are self-lubricating and dry-running, there was no need for the bottling plant to use additional greases or other lubricants, which carry their own environmental problems. We’re very proud to be part of this solution that will save both water in Auckland and money for this customer. Win-win for all.”

For more information, contact Supply Services Ltd. at 67 Newton Street, Mt. Maunganui, 3116 New Zealand; phone +(64) 7-575-0125, fax +(64) 7-575-0210, sales.mtm@supplyservices.co.nz or www.supplyservices.co.nz.