The global COVID-19 pandemic has precipitated the widespread deployment of the first generation of transparent safety shields. Schools, retailers and restaurants have been looking for the next-generation of performance plastic that would offer additional benefits for safety shield installations by providing an additional line of defense between cleanings.

“The deployment of safety shields is an important part of reopening plans for businesses, schools and institutions,” said Dr. Ted Trautman, technology director for PLASKOLITE. “AMGARD protects the sheet against the growth of microorganisms such as mold and mildew. AMGARD delivers the dual benefit of a physical barrier and an antimicrobial technology designed to protect the plastic’s surface.”

“Responding to the need of our customers and our community for an antimicrobial surface, PLASKOLITE’s new product development team rose to the challenge and developed AMGARD,” said Ryan Schroder, president and CEO of PLASKOLITE. “Thank you to our team who spent long hours accelerating the development and testing of this ground-breaking acrylic and polycarbonate sheet.”

Manufactured in the United States, AMGARD is available for sale through PLASKOLITE distributors nationwide. www.plaskolite.com.

With Makrofol EC polycarbonate film, customers can benefit from a more sustainable alternative to standard polycarbonate films that exhibits comparable or even better properties, including improved chemical and weather resistance. This partly bio-based film also offers excellent mechanical properties and impact strength, high abrasion resistance and surface hardness as well as good optical properties.

Makrofol EC polycarbonate films can be processed by a variety of technologies, including printing, thermoforming, high-pressure forming (HPF), coating (hardcoat, adhesive), cutting and lamination.

Similar to conventional polycarbonate films, Makrofol EC polycarbonate film can be used in a variety of applications spanning several industries, including:

- Automotive: Speedometers, decorative trim parts and instrument clusters

- Electrical, electronics and appliances: Electrical insulation, electronic housing and decorative control panels

- Graphics: Labels, tags, overlays and signage

- Packaging: Thermoformed packaging for sensitive goods

Makrofol EC features excellent mechanical properties and impact strength, weather and chemical resistance and high abrasion resistance and surface hardness. www.films.covestro.com.

Made of ethylene-chlorotrifluoroethylene, the SYGEF ECTFE system offers excellent physical properties. The high-performance fluoropolymer material allows use in a broad temperature range from -105°F/-76°C to 284°F/140°C, and with aggressive chemicals approved between 32°F/0°C to 176°F/80°C.

SYGEF ECTFE is available in pipe, valves and fittings from 1/2″ – 4″ (d20 – d110 mm) and features quick assembly, long service life and lower initial costs than welded PFA systems. When compared to PFA, SYGEF ECTFE has a 200 percent higher pressure range and 20 percent more efficiency in pipe volume. Combined, these attributes provide more efficient processes, a higher safety standard and higher flow rates in equal or less space. Used in combination with GF’s latest IR welding technology, the IR-110A, the SYGEF ECTFE system provides the highest level of safety for people, the environment and the production process.

“Safety is the number one concern in applications with acids and other toxic chemicals,” said Brian Gordon, head of product management for GF Piping Systems. “This system offers the exceptional reliability that affords owners, plant operators and technicians the peace of mind they need for safe and efficient operation.”

With good chemical resistance, excellent abrasion resistance and high impact strength, ECTFE meets all the requirements for demanding industrial environments, such as chemical processing, water treatment and microelectronics. www.gfps.com.

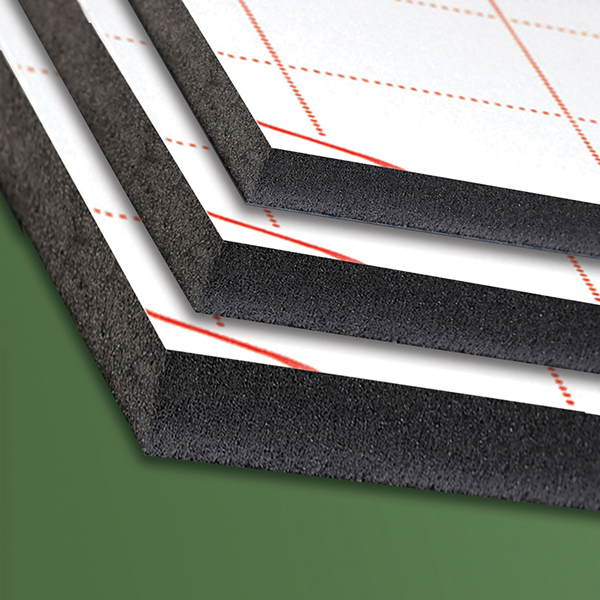

GATORFOAM SELF-ADHESIVE eliminates the need for pressure-sensitive adhesive stock, saving fabricators time and material costs. This extremely rigid and durable foam board offers excellent dent and scratch resistance while its black foam center provides a clean, finished appearance to projects. GATORFOAM SELF-ADHESIVE is a lightweight high-performance substrate that offers good dimensional stability. It routes and cuts cleanly for easy fabrication. Simple mounting instructions are included on the board’s removable red liner.

“We’ve expanded our line of high-performance GATOR® graphic display boards with GATORFOAM SELF-ADHESIVE as an easy and efficient option for mounting projects,” said Chuck Kunze, director, product management and marketing, 3A Composites USA, Inc. “GATORFOAM SELF-ADHESIVE offers the same rigidity, durability and dimensional stability that graphic designers and fabricators have come to expect from original GATORFOAM but with the added value of high-tack adhesive already applied to one side of the board. Fabricators can save time and money in materials when mounting projects on GATORFOAM SELF-ADHESIVE.”

GATORFOAM SELF-ADHESIVE is suitable for projects with medium-term application lives, including: point-of-purchase and point-of sale displays; exhibits and kiosks; interior signage and displays; framing; hanging signage; window displays, promotional campaigns, 3-D displays; and dimensional letters. Recommended fabrication methods include mounting, repositioning vinyl, saw cutting and routing.

GATORFOAM SELF-ADHESIVE is available with black facers and black foam in 3/16″, ½” and ¾” gauges in stocked 48″ x 96″ sheets. Custom sheet sizes are available in minimum quantity orders. www.3acompositesusa.com/display.

Drake made this shape to “lean out” production of parts that were being machined from 1.25″ x 12″ (32 mm x 305 mm) wide Torlon plate. The material savings approaches 50 percent with the added benefit of reduced machining time enabled by turning blanks rather than milling them.

Another success story comes from an Australian dairy and cheese producer who needed to produce a 10″ (254 mm) solid piston for a product-filling machine. The piston had to be FDA-compliant for direct food contact. The piston had to be solid, eliminating the pathway for bacteria, viruses and parasites to enter during the filling process. PEEK was chosen for its unique combination of properties, exceptional mechanical performance, superior wear characteristics and outstanding chemical and steam resistance (clean in place). The requirement for solid rod eliminated compression molding as a method of manufacturing. With their extrusion and process development capabilities, Drake was able to successfully extrude the 10″ (254 mm) rod x 48″ (1219 mm) long billet and deliver it to Australia within six weeks.

This larger diameter rod will enable Torlon and PEEK to serve new applications in aerospace, semiconductor, military and food processing applications.

Drake’s large diameter Torlon rod is made from AMS 3670 and ASTM D5204 compliant resins. Drake’s large diameter PEEK rod is made from Mil-P 46183 and ASTM D6262 compliant resins. The ultra large rod is made possible by proprietary Drake designed and built extrusion equipment. Large diameter rod is available at Drake Plastics Ltd. Co. in multiple Torlon and PEEK grades, in stock or made to order with industry short lead times. www.drakeplastics.com.

In addition to parts, customers can find customized training on a variety of topics as well as service and support via remote diagnostics or scheduled onsite visits. www.cncshop.com.

Braskem’s INSPIRE series of value-added polypropylene products offers enhanced performance attributes delivering performance and sustainability. The new grade has optical properties that approach PET, with improved thermal properties over PET and traditional random copolymer polypropylene. The new grade is suitable for thermoformed applications that demand clarity and heat resistance, such as store and restaurant preprepared and ready-to-heat meals. Due to the improved heat resistance, these containers are dishwasher safe.

Alexandre Elias, Braskem America vice president, polyolefins commented, “Our INSPIRE series offers an attractive balance of performance and sustainability with a simplified pellet management solution. The INSPIRE series allows thermoformers to use a single pellet for a wide range of applications that require varying levels of stiffness, clarity or impact creating a simplified inventory approach. This latest polypropylene grade is designed as an ideal solution to replace PET because of its recyclability and unique properties.”

In June, Braskem announced the construction completion of its polypropylene production line in La Porte, TX, USA. Braskem’s new facility has a designed production capacity of more than 450 kilotons (kt) or 1 billion pounds per year and has the capability to produce the entire polypropylene portfolio including a broad range of polypropylene products including homopolymer, impact copolymer and random copolymers. Initial production test runs began in July with the first full-scale commercial production activity expected in the third quarter of 2020. www.braskem.com.

TUFFAK WC is designed for welding curtain and screen applications. It offers the high temperature resistance and optical clarity and protection required for arc welding applications with a combination of impact strength, light weight and flexibility superior to traditional alternatives such as vinyl strips and sheets. These characteristics also make TUFFAK WC well suited for other applications requiring UV light blocking, including screens in tanning salons and enclosures, walkways and other areas under intense sunlight.

TUFFAK WC is available in four transparent colors with high optical clarity: light yellow, medium amber and red, as well as dark green. It is certified to AWS F2.3M:2011 for transparent welding curtains and screens for light transmission.

TUFFAK LS delivers similar benefits at targeted wavelengths specific to lasers, protecting the eyes and skin from accidental exposure in medical, dental, dermatological, CO2 cutting and research applications. It is designed for use in door and room windows, as standing panels and movable screens, modular barriers and tabletop laser enclosures. TUFFAK LS is available in three standard, transparent colors: IR blocking light gray, visible light blocking bright amber and UV blocking yellow. All colors maintain high optical clarity and visibility. It is certified to ANSI Z136.7: Testing and Labeling of Laser Protective Equipment.

“Welding and laser operations require extreme eye and skin protection due to the intense and harmful light given off by the process,” said Jeff Bostic, vice president of the polycarbonate division of PLASKOLITE. “TUFFAK WC and LS screens provide protection to operators and others in the immediate vicinity. Traditional materials used to deliver this protection have been flimsy and damage easily. TUFFAK WC delivers all of the necessary protective qualities but with the benefits of polycarbonate sheet, specifically light weight, toughness and ease of fabrication.”

TUFFAK WC and LS are extensions of PLASKOLITE’s TUFFAK polycarbonate sheet line, which is used in safety shields, signage, face shields, mass transportation glazing, skylights, force entry and ballistic applications, as well as many other applications requiring a combination of strength and light weight. www.plaskolite.com.

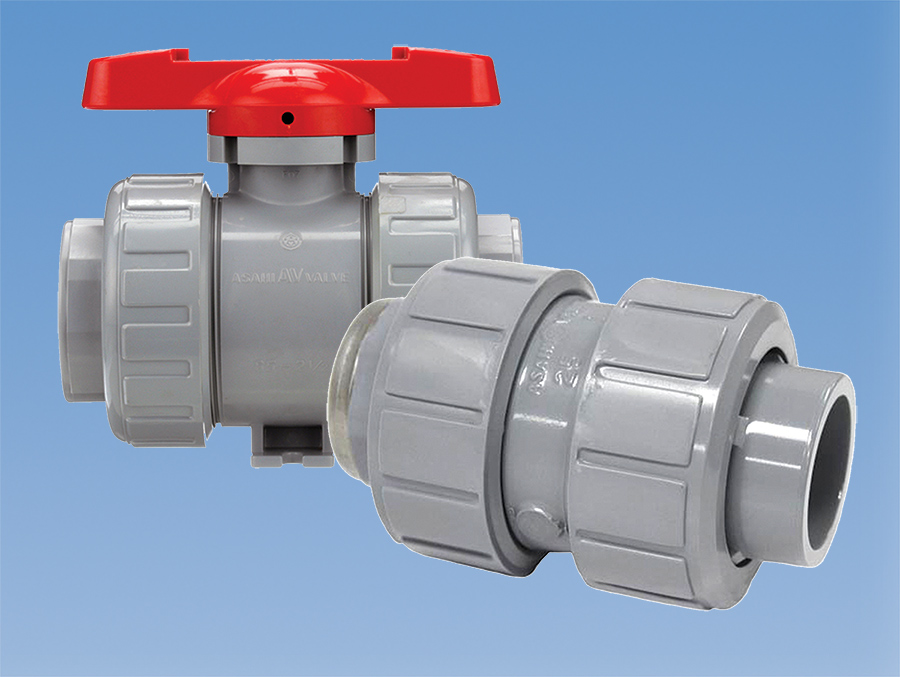

Type-21 ball valves with CPVC bodies and EPDM or FKM seats and seals, as well as ball check valves with CPVC bodies and EPDM or FKM seats and seals meet the requirements of NSF/ANSI/CAN Standard 61 – Drinking Water Components.

Available with socket, threaded or flanged (ANSI) end connections, Asahi/America Type-21 ball valves are pressure rated up to 230 psi and are full vacuum rated in all sizes. Double O-ring seals on the stem add protection and a tapered O-ring groove helps keep end connector O-rings on the valve body during installation. With an integrally molded ISO mounting pad, Type-21 ball valves can be operated manually or actuated. An integrally molded base pad allows valves to be mounted securely or panel mounted. True union design allows for easier installation and repairs without expanding the pipe system. The Type-21 ball valve blocks in two directions, upstream and downstream, which leaves full pressure on the opposite end of the valve.

Asahi/America ball check valves are true union in sizes 1/2″ through 2″ and single union in 3″ through 4″. The solid thermoplastic ball is the only moving part, which unseats to permit flow in one direction, but seals against the seat to prevent backflow. Ball check valves may be used vertically or horizontally, have a minimum shut-off of 5 psi and all sizes rated for full vacuum service. www.asahi-america.com.