Swiss lighting manufacturer Regent Lighting developed the JOKER table luminaire with the goal of bringing a professional luminaire to market that provides pleasant lighting for those working from home — in close collaboration with Jungbecker, a company from Olpe, Germany, that specializes in plastic optics. Their material of choice for the optics is ACRYLITE®, the brand polymethyl methacrylate (PMMA) from Röhm in the Americas.

The integrated Tunable White technology makes it possible to control the color temperature at the push of a button. This not only makes working at home more pleasant, but enables everyone to work with the light that they prefer, even in a large open-plan office.

“We did not want to design the 550th table luminaire with a swivel arm, but come up with something completely different,” said Kornelius Reutter, project manager for design and innovation at Regent Lighting. “Especially since the technological advancement with LEDs and optics allows for shallow constructions which are favorable to shapes that are in line with the Regent Lighting design philosophy: timeless, clearly designed luminaires with highly intelligent lighting technology.” With his designs for JOKER, Reutter followed three guiding principles: Light is simple. Light is personalized and serves people. And the luminaire fits in harmoniously with the architecture and the space.

The designer got his inspiration for the surface light from infinity pools — swimming pools in which the water appears to be contained without a visible barrier. The implementation was successful: when the luminaire is on, the view is of a free-floating, homogeneous light area. The frame of the light guide made from ACRYLITE is barely visible and no light emission is visible from the side.

This innovation is the result of the high demands Regent Lighting places on light design, the development and processing skills of Jungbecker and the optical properties of the ACRYLITE molding compounds from Röhm. “It is crucial that the material absorbs as little light as possible. Highly transparent ACRYLITE is ideally suited here,” said Fabian Bürkli, project manager for research and development at Jungbecker.

The optics for JOKER are produced in a special production process. In the first process step, the ACRYLITE molding compound is made into a v-shaped blank with small cones at the thicker end, the optical couplings for the LEDs. In the second step, extremely fine microstructures are stamped into the light guide in a hot-stamping process.

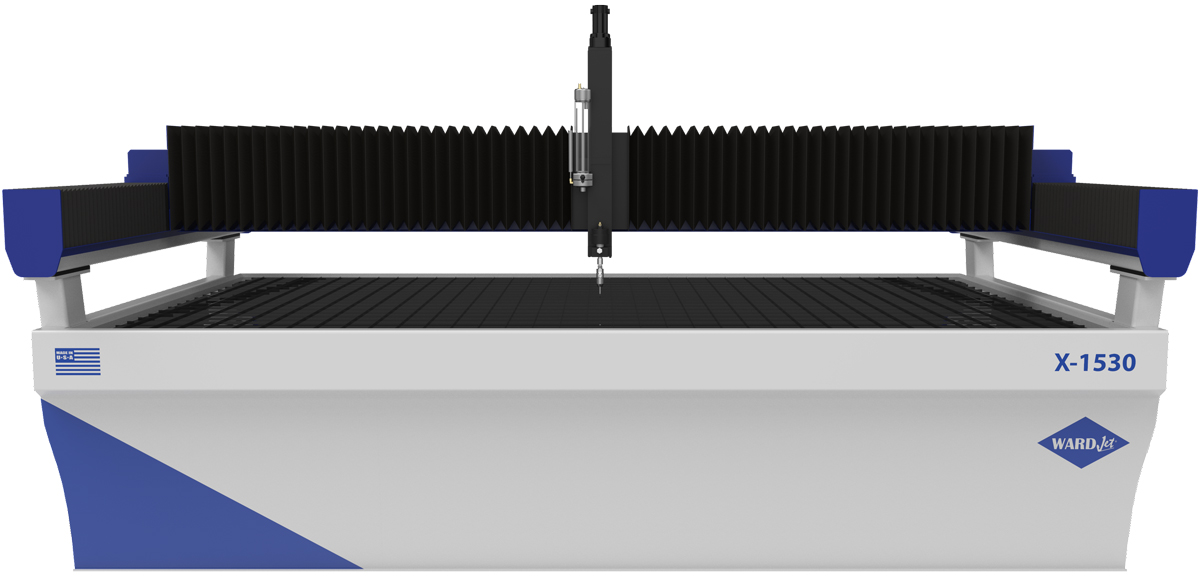

The X-Series is a purpose-built machine that increases productivity for a range of applications. It can be configured with multiple head/tool options, and its tanks feature internal channel and upright supports. With 1/4″ steel as standard (compared to 1/8″ or smaller in some competition) the X-Series provides heavy-duty construction and a drive system designed for long-term ownership. www.cncshop.com.

Gelmart has designed, developed and produced more than 1.25 billion units in underwear, bras and shapewear for the world’s biggest retailers and brands. Gelmart’s kindly bra line is the culmination of more than three years of development, resulting in the world’s first mass-produced, plant-based bra. The kindly product line aims to connect the worlds of sustainability, accessibility and innovation by incorporating more environmentally friendly materials such as Braskem’s I’m green EVA biopolymer, replacing the use of traditional foam materials.

Edison Terra, executive vice president of Braskem, commented, “As a global leader in bio-polymers, Braskem has a long-standing commitment to creating a more sustainable future. Our innovative portfolio of I’m green plant-based materials is helping global consumer brands and manufacturers transition from legacy fossil fuels based raw materials to more eco-friendly solutions. We couldn’t be more excited to announce our partnership with Gelmart. Their visionary leadership is helping transform the world’s apparel industry with creative new offerings that bring the same high-quality and comfort, but also deliver a more sustainable footprint on the planet.”

Gelmart International CEO Yossi Nasser stated, “We’re thrilled to bring the world’s first plant-based bra cup to market, but real sustainability does not exist without accessibility. It’s important to us that our brands are known not only for quality products, but more for creating a movement toward a more eco-friendly and attainable lifestyle for all. Finding the right partner to provide the high-quality eco-friendly materials at scale was an essential factor in our strategy. Braskem was the natural choice for us as a leading supplier of biopolymers, their deep expertise in Green EVA and their collaborative approach were a perfect fit.”

Braskem’s I’m green bio-based EVA is sustainably produced from sugarcane, a renewable source that contributes to the reduction in greenhouse gas emissions by CO2 capture. It is suitable for use in apparel, footwear, children’s toys, general foams and more.

Giancarlos Delevati, account manager and business development of Braskem, commented, “Today’s consumer is taking a more holistic approach when making their purchasing decision and this increasingly calls for selecting products that are developed and produced with a focus on sustainability as a primary consideration. At Braskem, we partner with our customers to help them make the transition from legacy materials to more environmentally friendly materials. We are proud to work with Gelmart to help move the apparel industry forward on its sustainability journey and deliver products that meet the needs of their customers who are passionate about creating a better future for the planet.”

Eve Bastug, chief product officer of Gelmart International, stated, “In my 40-plus years working in the industry, this was the most challenging project I’ve worked on — and it certainly feels the most rewarding. It took us three years to work toward a sustainable cup that is more than 80 percent plant-based. Our goal is to never make consumers choose between function, plant and price, by creating a more sustainable future with beautifully crafted products that people can feel good about wearing.” www.braskem.com.

Curt Wolff of the American Wheelchair Bowling Association (AWBA) came to Colorado Plastic Products with a challenge: he had an old parabolic ramp made from 1/2″ polycarbonate and was looking for something newer and more affordable so more wheelchair bowlers can get back out on the lanes.

The new generation of ultrafiltration membranes is produced by Polymem, a French manufacturer of modules for water filtration, and made from Kynar PVDF resin. The material demonstrates long-term resistance to oxidants and mechanical strength in a microporous structure. The water to be treated passes through the microporous fibers, like hollow spaghetti less than one millimeter in diameter, to be ultra-filtered with the scale of the pores in the 10-20 nanometers range. Repeated, long-term cleanability is a key feature of these membranes. Due to the long-lasting hydrophilic property of the membranes, filtration throughput is high while cleaning frequency is between 20-30 percent lower than with other polymer materials.

“Working hand-in-hand with Polymem and downstream users enables us to move faster and to accomplish far greater results than simply working alone. It is an outstanding example of a market driven solution,” said David Silagy, general manager for fluoropolymers at Arkema.

“It is an extremely safe system. After passing through the membranes, all suspended solids and any elements in the order of 15 nm including bacteria and viruses are eliminated. The system thus perfectly fulfills its role regarding everything that is pathogenic, offering the best guarantees to prevent issues of quality non-conformity,” stated Julie Ducrot, process and water treatment engineer at the Toulouse Métropole Cycle de l’Eau Department. “The treated wastewater we obtain is top quality that is suitable for its intended use, namely currently just the watering of green spaces (within the facility as well as the nearby golf course).”

The reuse of treated wastewater is strongly encouraged by public policies in France, in that it helps adapt the country to climate change. The goal is to reduce the pressure on water resources, but also to reduce the products needed for treatment and the energy cost in comparison with other technologies. www.arkema.com.

One of the main design challenges with this project was determining the constructability of the proposed upgrades due to the size of the pipe and structures. In the areas where the pipe would be installed, there were site constraints that limited the length of pipe that could be installed as well as the available working space required for installation.

To overcome installation constraints, engineers used two sizes of AGRU HDPE pipe, which provided enough flexibility to allow the contractor to complete the installation while also managing the site constraints. Horizontal directional drilling (HDD) was used as the installation method.

Additionally, because some segments of the existing system could not be increased in diameter, the engineer designed a solution that utilized sections of 48″ and 63″ diameter pipes in SDR 11.

The project’s construction is ongoing, but the contractor has been able to successfully install the pipes without issue. Furthermore, the engineering team’s choice of piping product and installation approach have already provided significant time savings as the alternative would have been tunneling under the creek. Once completed, this project will become the largest OD HDPE HDD project in North America. www.agruamerica.com.