he installation of clear temporary thermoplastics sheets as safety shields protects employees and customers from the spread of airborne virus such as COVID-19. The business community has realized that safety shields will be a part of the new normal for some time to come. However, a primary concern is keeping these safety shields looking their best.

Proper cleaning will help ensure your safety shields enjoy a long in-service life. Cleaning and disinfecting best practices for acrylic and polycarbonate safety shields as described in this article are important to keep them looking great.

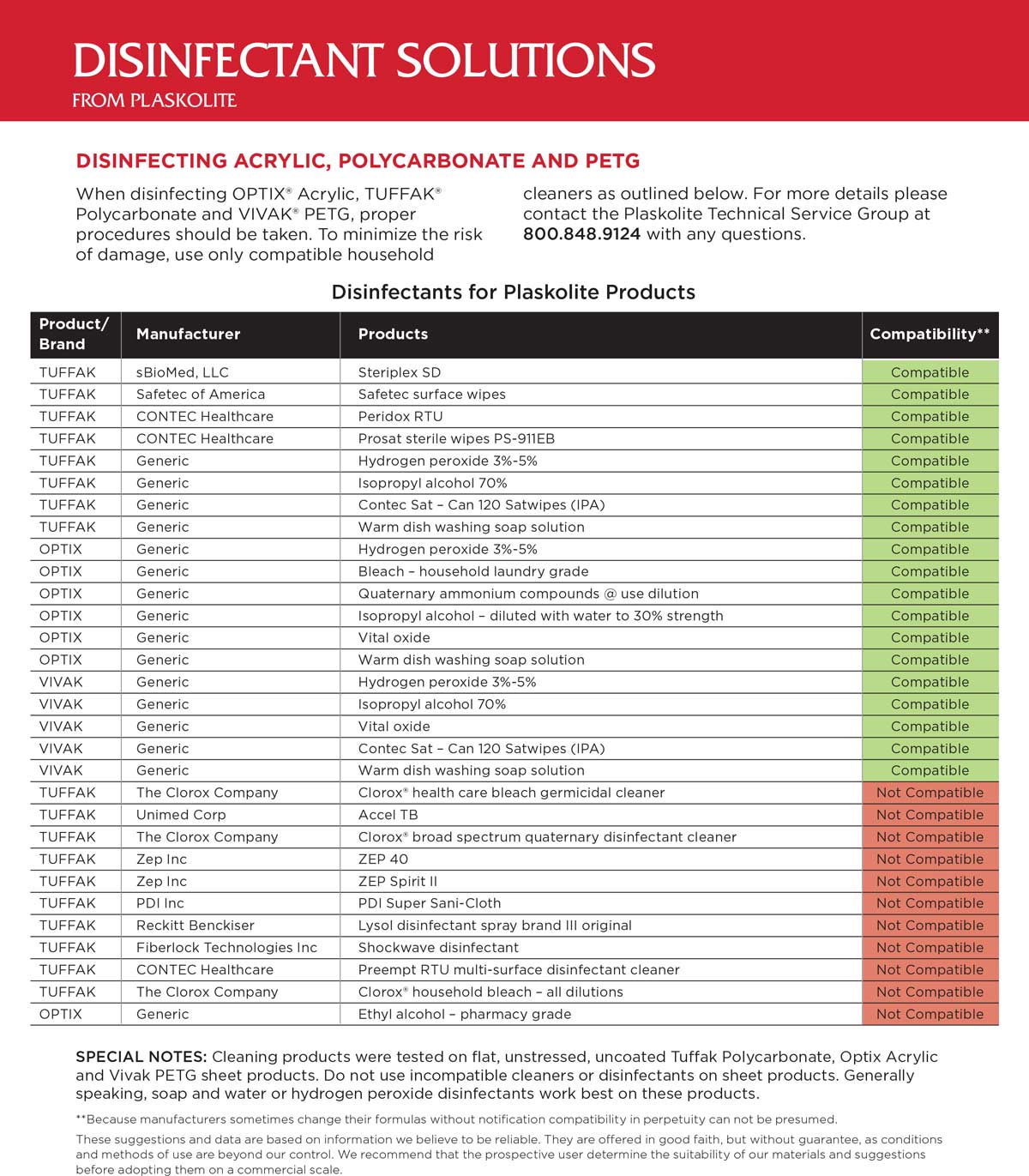

Acrylic sheet can be cleaned with a mild soap solution or a commercially available plastic cleaner and a lint-free cloth. To remove grease, oil or tar deposits, use hexane or kerosene, followed by a mild soap solution and clear water rinse. Avoid cleaners containing alcohol.

Polycarbonate sheet products are available in uncoated and coated options. To clean an uncoated sheet, thoroughly pre-rinse the sheet with warm water to loosen and wash away surface residue, grit and grime. Using a soft microfiber cloth or moist non-abrasive sponge, gently wash with a mild diluted soap or detergent. Rinse completely with clean water. To prevent water spots, finish with a dry soft cloth.

Note that the edges of coated polycarbonate sheets are not protected with the chemical-resistant coating. Therefore, prevent the exposure of these edges to incompatible cleaning solutions and solvents. Always rinse edges thoroughly with generous amounts of lukewarm clean water.

For an additional line of defense between cleanings, antimicrobial treated options are available in coated and uncoated acrylic or polycarbonate safety shields. Antimicrobial additives such as silver ion technology protect the sheet by continuously reducing microbial growth, keeping the surface free from microbial degradation. Such antimicrobial additives are incorporated into the sheet and are not wiped away during regular cleaning and can last the lifetime of the safety shield.

Tip from the experts: When cleaning the surface of the sheet, it is important to remember to prevent the cleaning solution from running down the surface of the sheet and pooling along or in the framing’s edge engagement. If this happens, the cleaning solution can remain wet against the unprotected edges of the sheet for an extended period, giving the solution time and opportunity to chemically attack the exposed edge.