of

Cover photo courtesy of Vycom.

Solving Today’s Design Challenges

Additives

Advantages and Guidelines

Safety and Design Options

Properties with Additives

How to Maximize Plastic Performance with Fewer Additives

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

IAPD President

lot has changed in the world since we entered the “lock-down” because of COVID-19. Now, with more people getting vaccinated, we can start looking forward to life returning to something that’s closer to “normal.” Our post-COVID life may look different than what it was like before March 2020, but we are resilient and we will make it work. I’m happy to see that associations, like IAPD, are scheduling in-person conferences and tradeshows again, and I look forward to seeing you all in Louisville, KY, USA in August at IAPD’s Annual Convention. In addition, companies are beginning to reestablish travel and, most importantly, we can start to plan much-needed vacations outside our homes.

IAPD CEO

he Toxic Substances Control Act (TSCA) was originally passed by Congress in 1976. It gave the Environmental Protection Agency (EPA) the authority to require reporting, record-keeping and testing requirements, as well as restrictions relating to chemical substances and mixtures. In 2016, it was overhauled, updated and signed into law as the Frank R. Lautenberg Chemical Safety for the 21st Century Act.

While the legislation was being drafted, IAPD’s government relations (GR) team became aware of an effort to push material testing downstream. Language in an early draft of the legislation would have moved the responsibility for product testing from the resin companies to manufacturers and distributors. This change would have been both expensive and devastating for IAPD members. Due to the cost of testing alone, it’s possible that many IAPD members would have been forced to go out of business.

SWM International recently launched ArgotecTM 49510-60DV-AM anti-microbial film. It is a high performance aliphatic TPU material with an additional antimicrobial TPU hard coat top layer. The top layer is formulated with a zinc-based formula to provide antimicrobial properties that protect against the growth of mildew and bacteria. It is designed to protect shared surfaces that may regularly be in contact by multiple users. Applications include electronic displays, touch screens, vending machines, public transportation handles and other shared surfaces. It has been effectivity tested against standard JISZ-2801 and provides excellent performance, according to the company.

IP Retail is a world leader in supermarket design, retail design and décor fabrication that serves independent and chain retailers to provide customized solutions that connect with their clientele. At its plant just outside of Cincinnati, OH, USA, the company runs an extensive design, project management, engineering and fabrication operation, including digital printing and routing processes to create bespoke visual display experiences. The company operates wide-format digital printers, cutters and routers over two shifts, using a variety of substrates including Celtec® expanded PVC sheets from Vycom.

Being “Aware of the World” is a core value of CIP Retail and it strives to use materials and processes that minimize the company’s footprint and conserve resources. Keeping true to this value presented a conundrum: as a considerable user of PVC and other plastics, how could it also reduce its environmental impact? The company had amassed a significant quantity of PVC scrap over the years as it searched for a solution to prevent it from going to a landfill.

he installation of clear temporary thermoplastics sheets as safety shields protects employees and customers from the spread of airborne virus such as COVID-19. The business community has realized that safety shields will be a part of the new normal for some time to come. However, a primary concern is keeping these safety shields looking their best.

Proper cleaning will help ensure your safety shields enjoy a long in-service life. Cleaning and disinfecting best practices for acrylic and polycarbonate safety shields as described in this article are important to keep them looking great.

urbell Plastics, Inc. recently donated more than 2,500 pounds of plastic materials to the international nonprofit Range of Motion Project (ROMP).

While attending the American Orthotic & Prosthetic Association (AOPA) exhibition in San Diego in 2019, Jeff Wilson, senior business development manager – Curbell O&P, met Lauren “LP” Panasewicz, director of development at ROMP. Learning about ROMP’s mission to provide high quality prosthetic care in underserved populations to enhance mobility and unlock human potential captured Wilson’s attention. In early 2020 as Curbell O&P was consolidating their Arlington, TX, USA locations, Wilson remembered that conversation. Even with a new optimized racking system, Curbell O&P realized they did not have enough space to house the inventory of two locations in one. Taking a look at the extra plastic materials, which included uncommonly used sheet sizes for O&P fabrication, Curbell staff compiled a list of EVA materials for flexible inner liners (OP-TEK® Flex, OP-TEK® Flex Comfort and Proflex with silicone), Polypro, Copoly, LDPE and Orfitrans™ Stiff.

y two favorite questions from those new to the plastics industry are: How did we get so many plastics? and How do you select the best material for a given application?

It’s impossible to answer either question without discussing the role of reinforcements, additives and blends on the properties of plastics and the influence they have on the number of material choices engineers have today. The number of polymers is finite, although trying to get performance plastics professionals to agree an actual number may be challenging. Let’s say there are less than 100 unique chemistries that we identify as manmade polymers (i.e., plastics). They include:

- Polyolefins such as polypropylene (PP) and polyethylene (PE) in all their forms and molecular weights; nylons in all their chemistries (approximately 10 varieties)

- Acetals

he most common additives used in manufacturing polymer sheets are colorants. Customers typically have a strong vision of what they want their product to look like, and the first attribute in generating that look is the color. So how do you generate color? The answer is not always simple, because colorant packages behave differently depending on the use conditions. For example, products intended to be used primarily indoors or for which outdoor use and exposure is short have different color stability requirements than products that are intended to be used extensively, or exclusively, outdoors.

How does an end user determine color requirements? Is it simply understanding interior vs. exterior use? This article can help provide a pathway to first understand how to choose between types of colorants and how to make sure the choices are the right ones.

itigating the presence of microorganisms on plastic parts has become a priority for consumers since the COVID-19 outbreak. In response to these concerns, a wide variety of plastic products are being treated with antimicrobial additives, such as:

- Floor coverings, exercise equipment and cutting boards

- Door or floor mats, bed rails and shopping carts

- Food distribution carts and trays

- Pallets and playground equipment

- Storage containers, waste bins and luggage

These antimicrobial additives provide inherent microbe-fighting properties that control the spread of bacteria, fungi and algae on the surface of treated products. Antimicrobials prevent microorganisms from growing, producing energy and/or replicating when the microbe encounters the protected surface.

Gears, machine parts, sprockets, star wheels, wear strips and more.

Gears, machine parts, sprockets, star wheels, wear strips and more.

aw material additives play an important role in the manufacturing of extruded sheet products. Additives can be used to aid in more efficient manufacturing — allowing for easier production — and they can be used to enhance the features of finished products, providing greater application benefits. Here are some examples of how additives contribute to materials that enhance safety and provide creative design options.

ltra-high molecular weight polyethylene (UHMW-PE) is a high-performance plastic resin that is commonly converted via compression molding and ram extrusion into sheet, rod, tube, film and profile shapes. These products are typically machined into industrial parts often used in applications demanding a low friction coefficient and/or stout resistance to impact and abrasion, such as truck bed liners, hopper and chute liners, bearings, bushings, sprockets, wear strips, chain guides and marine fendering.

While UHMW-PE in its virgin natural state is considered one of the highest performing thermoplastics currently available, the preprocessed resin will also almost limitlessly accept liquid or dry additives, which can enhance or add performance characteristics or minimize negative attributes. When properly disbursed, the benefits of additives will generally be consistent throughout the cross-section of the material. There are also coating materials that can completely transform UHMW-PE’s surface while maintaining all the toughness of the base virgin material.

esins such as high-density polyethylene (HDPE) are inherently capable of being manufactured into highly capable products. With minor alterations to the chemical composition of the mixture through additives, manufacturers can enhance the performance of the material in certain areas to meet more stringent project demands. While additives can bring new capabilities to plastic products such as geosynthetics, some additives can migrate out over time, causing the products to lose those benefits. For this reason, manufacturers should consider the qualities of the chosen resin first.

This article describes the purpose of additives in plastics, how the performance of plastic products can be improved through a materials-first policy and ways manufacturers have leveraged the benefits of coextrusion to min-max the benefits of certain additives.

Black

Hopkins

Fisher

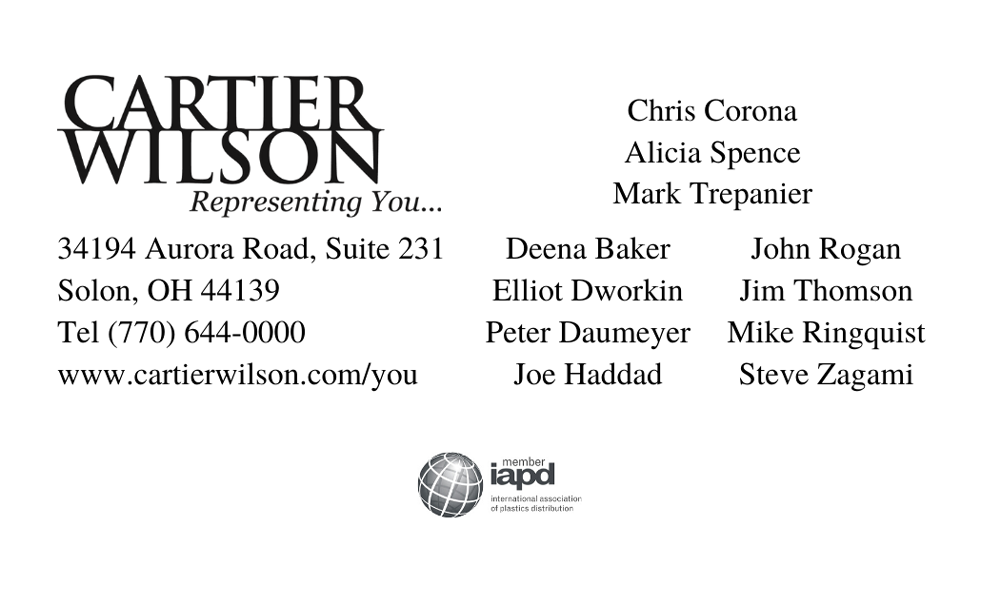

“Mick, being a longtime friend and partner of CartierWilson, is an ideal fit for our team. His experience and knowledge of engineering plastics, combined with his strategic vision, brings tremendous value to our distribution, OEM, manufacturer partners. We look forward to Mick continuing his legacy of being an advocate for performance plastics in the Great Lakes territory,” said Principal Chris Corona.

“I am pleased to be part of an organization that exhibits energy, integrity, and sincerity in helping companies, as well as their people, reach their full potential,” stated Fisher.