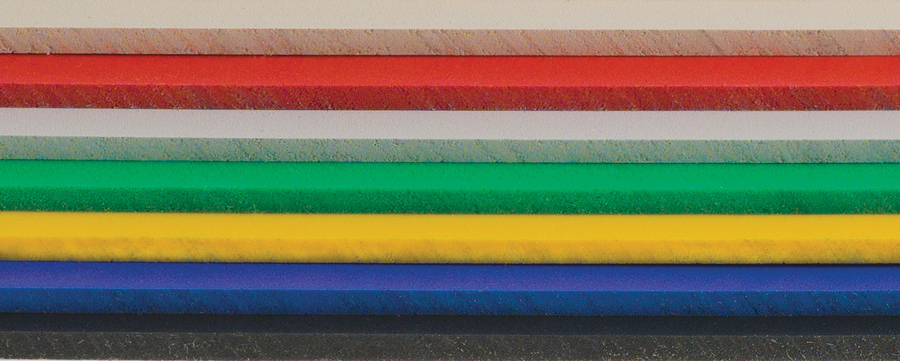

he most common additives used in manufacturing polymer sheets are colorants. Customers typically have a strong vision of what they want their product to look like, and the first attribute in generating that look is the color. So how do you generate color? The answer is not always simple, because colorant packages behave differently depending on the use conditions. For example, products intended to be used primarily indoors or for which outdoor use and exposure is short have different color stability requirements than products that are intended to be used extensively, or exclusively, outdoors.

How does an end user determine color requirements? Is it simply understanding interior vs. exterior use? This article can help provide a pathway to first understand how to choose between types of colorants and how to make sure the choices are the right ones.

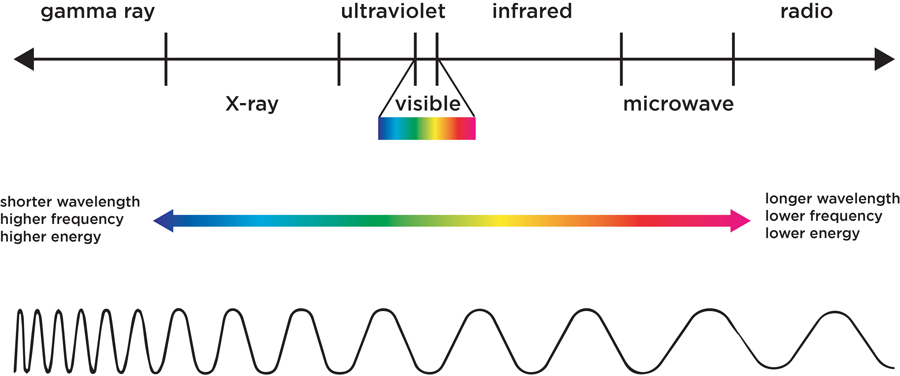

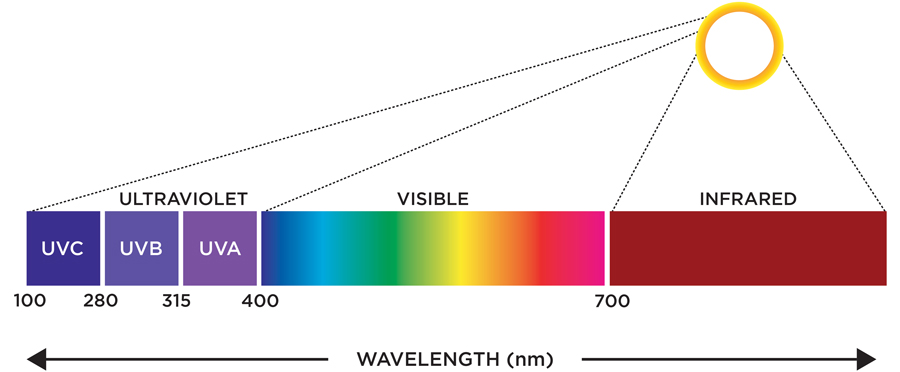

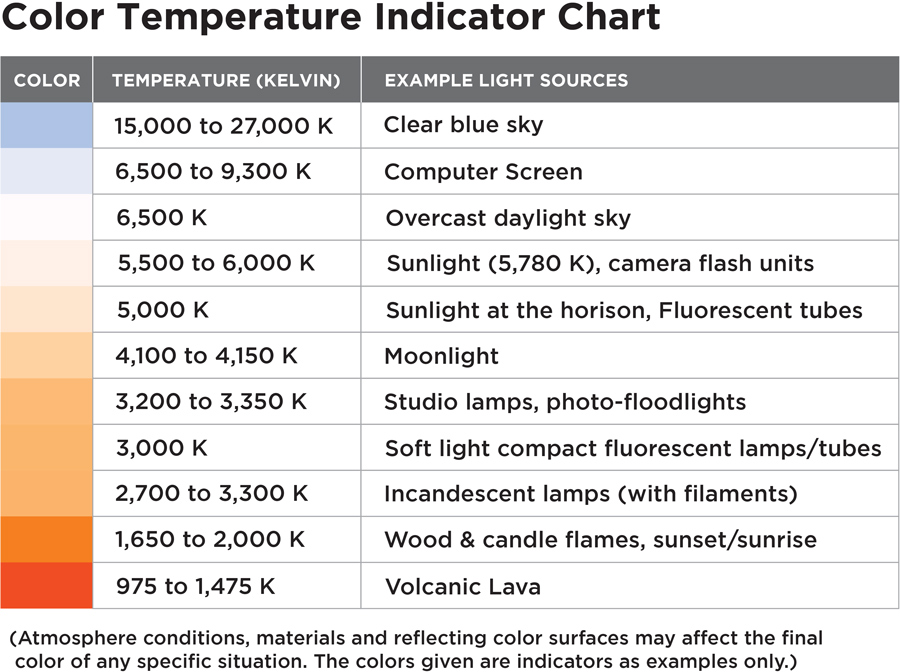

Color is a perception, based on how the human eye interprets visible light that is reflected from objects. Visible light is electromagnetic radiation (figure 1) that is generated by a variety of sources that can be detected by the human eye. The order of colors corresponds to the energy of the light in the visible light spectrum, from red (lowest energy and longest wavelength) to violet (highest energy and shortest wavelength).

Now that you have defined the product’s usage environment, the next step in specifying color is ensuring that the colors can survive in that environment. The key environmental differences are between interior and exterior applications, and again the type of light plays an important role. For this part of the specification process, you need to delve deeper into the materials science of colorants.

Dyes, in contrast to pigments, are almost all synthetic today, although many were originally discovered and harvested from natural resources. An example is indigo, the color used for blue jeans. There are thousands of dyes available today. The biggest advantage of dyes is the intensity of their color when compared to pigments: A little bit goes a long way. Dyes used in conjunction with pigments can help simplify and accelerate color matching. However, many dyes — particularly blues, oranges and reds — do not retain their color over time in outdoor environments. Because of the potential for fading, dyes are most preferred for interior product applications, for products that have very short lifecycles and for which color fading would not be an issue.

- An antioxidant to improve the processing by the manufacturer and to enable re-use and recycling;

- A UV light absorber to intercept harmful UV light and dissipate it without harming the polymer; and

- A hindered amine light stabilizer (HALS) which acts as a synergist to the UV light absorber.