SWM International recently launched ArgotecTM 49510-60DV-AM anti-microbial film. It is a high performance aliphatic TPU material with an additional antimicrobial TPU hard coat top layer. The top layer is formulated with a zinc-based formula to provide antimicrobial properties that protect against the growth of mildew and bacteria. It is designed to protect shared surfaces that may regularly be in contact by multiple users. Applications include electronic displays, touch screens, vending machines, public transportation handles and other shared surfaces. It has been effectivity tested against standard JISZ-2801 and provides excellent performance, according to the company.

“Argotec 49510-60DV-AM film is designed for applications that require high optical clarity and low haze, making it perfect for touch screens,” said SWM International Commercial Director Arica Drake.

In a recent survey, a respondent commented, “I would recommend it because the benefits are quite influential and very helpful for the work area. We can stay safe while doing our daily work, controlling bacteria and preventing any contagion that damages our health.”

Key benefits of the material include:

- Formulated to protect against the growth of bacteria

- UV and stain resistance (non-yellowing)

- High durability, self-healing and scratch resistance

- Superior film gauge and gel control

- Non-adhesive and adhesive finished solutions available www.swmintl.com.

Densetec® Marine Board from Polymer Industries is specially formulated to withstand the rigors of harsh outdoor environments. It is UV-stabilized to resist damage and retain its beauty, even after years of direct sunlight. Densetec Marine Board does not splinter, crack, delaminate, rot, swell or absorb water like traditional materials. There is no need to stain or paint every few years, the color is integrated with the polymer and retains its vibrant appearance better than painted wood. www.polymerindustries.com.

Arkema will increase its fluoropolymer production capacities in Changshu, China by 35 percent in 2022. This investment is fueled by demand in the lithium-ion battery business as well as opportunities in the water filtration, construction coatings and semiconductor industries.

The Changshu plant was the company’s third global integrated PVDF production plant with the first batch of Kynar® PVDF produced on February 17, 2011. This plant, known as Arkema’s “Tiger Plant,” as it was constructed in 2010, the year of the Tiger, represented a major strategic step for Arkema in its commitment to supply global customers from each region. The plant was expanded several times over the decade, most recently in December 2020. Throughout its evolution, the plant has demonstrated a commitment to employee safety and product quality. It is capable of producing almost every grade in the fluoropolymers portfolio. www.arkema.com.

Palram Americas, Inc. recently launched a new series of antimicrobial surfacing and panel solutions for hygienic environments. These polymer sheets are versatile, durable, non-flammable, 100 percent recyclable and can withstand harsh chemicals and frequent cleaning cycles.

Built-in silver-ion technology inhibits the growth of microbes such as bacteria, mold and fungus which may cause odor, degradation, discoloration and staining of the product. It does so by disrupting the ability of these microorganisms to reproduce, helping to create a more hygienic product. As a print substrate, the antimicrobial surface protection of the sheet is unimpaired by ink coverage when the surfaces are digitally printed.

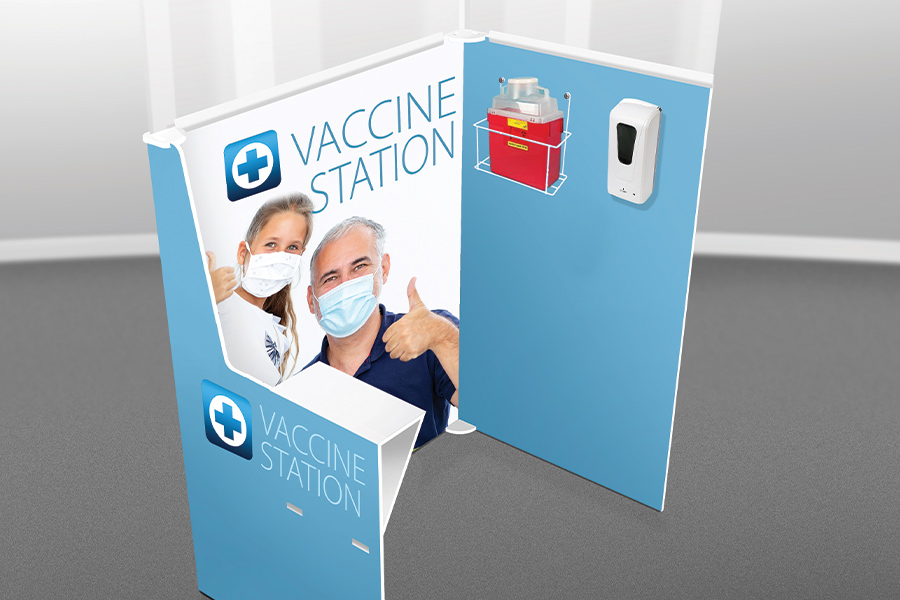

The HYG Series includes: PALBOARDTM HYG which is a multilayer polymer sheet that combines two rigid, ultra-smooth white surfaces with a white foam PVC core. It offers excellent ink adhesion and white index for vibrant color reproduction and is easy to cut and cold-bend using v-grooves. It is suitable for 3D structures, vaccine and sanitation stations, point-of-purchase (POP) displays, shelving, organized storage, retail signage and buy online/pick up in store (BOPIS) counters.

PALBOARD 3D MAX HYG is an extra-rigid variation that combines two black surfaces with a dense, black foam PVC core. The extra rigidity provides long-lasting durability in high traffic areas. The sheets have a fine hair-cell finish on one side, smooth on the other. 3D MAX can be heat-bent and cold-bent with v-grooves, providing endless possibilities. Offering superior ink adhesion, it can be hot stamped or digitally/silkscreen printed and is suitable for 3D structures, POP displays, cosmetic floor and counter-top displays, signage and exhibits.

PALCLADTM PRO HYG is a line of solid polymer sheets that are Class A fire rated and Clean Air GOLD certified (highest VOC certification for indoor air quality). Water resistant, these sheets can be laminated to base substrates such as PALIGHT® PVC, MDF, plywood or particle board. PALCLAD PRO HYG can also be thermoformed for a wide variety of applications. The material is suitable for vacuum formed medical device housings, covers and trays; sanitation stations; and as a laminate for ready-to-assemble furniture, countertops and cabinet doors.

Palram’s antimicrobial HYG products are already being used as the surfacing solution for many common areas in healthcare suites and hospitals, schools and universities, dormitories, locker rooms, gyms, daycare, long-term care, offices, retail environments and manufacturing facilities.

The antimicrobial technology does not protect users or others against disease-causing bacteria, germs, viruses or other harmful organisms. This technology is not a substitute for good hygiene and/or cleaning practices. www.palramamericas.com.

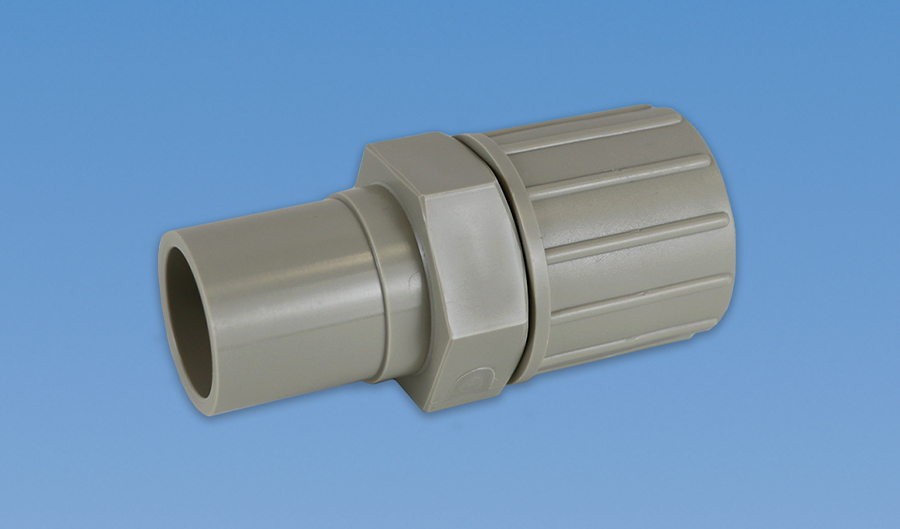

Asahi/America, Inc. now offers flare adapters for its PP-Pure® pigmented polypropylene piping system. The fittings are available now and in stock at the company’s Lawrence, MA, USA warehouse. PP-Pure flare adapters allow for a high purity transition between pigmented PP pipe and PFA tubing. Available in 1/2" – 1" pipe sizes and a variety of tubing sizes, PP-Pure flare adapters come cleaned and double bagged. Asahi’s PP-Pure piping system is best suited for low-end RO/DI applications and non-critical UPW lines in photovoltaic and semiconductor manufacturing. www.asahi-america.com.