SustainabilityCorner

The dedicated and diligent volunteers on the IAPD Recycling Task Force presented the Recycling Best Practices document to the IAPD membership at the 2022 Annual Convention in Tampa, FL, USA on September 13, 2022.

The following documents outline why your company should invest in a recycling program, high-level goals and steps to either begin or improve your current program.

IAPD – the performance plastics association is thrilled to provide this resource in the 2023 April/May issue of the Performance Plastics magazine. IAPD and the Recycling Task Force are confident that members will keep this document as a reference and a guide as they navigate how to incorporate a recycling program at their location or take their current one to the next level.

Why invest in a recycling program at your location?

Financial Benefit: The scrap you produce has value. Demand is increasing and supply is limited. Plus, recycling reduces landfill costs.

Support Customer Initiatives: Meet your customers’ sustainability goals, branding requirements and growth in a changing market.

Environmental Impact: Contributes to a circular economy, sustainability and the greater good.

Branding: Promote the value of your recycling program in your community and to the industry.

Risk Mitigation: If we aren’t recycling, there’s a greater chance that the government will demand it via legislation and regulation. This will impact the bottom line.

High-level goals include:

Meet growing customer and market requirements.

Create a net-positive financial impact by attracting new business opportunities.

Promote your program in the marketplace to improve your brand and generate goodwill.

Cost reduction potential.

How to begin recycling or improve your program:

Identify the most common polymers going into your dumpster.

Focus on the lowest hanging fruit: largest polymers by volume first.

Find local recyclers for those polymers. [online tool coming soon!]

Define how to measure your goals (KPIs).

For example:

Recycle 80% of your top 5 polymers.

Reduce landfill costs by 75%.

Create your own goals — this is your program to measure!

Pro Tip

- Get your company managers engaged!

- Your leadership must lead by example and embrace the program.

Establish a dedicated collection space.

- Critical for success: Effective polymer segregation and contamination control

- Make it obvious: Use an organized, clean, well-lit location with good signage.

- Storage: Your recyclers will help identify which polymers can be stored outside vs. inside and the volume requirements for pickup.

WHY DOES THIS MATTER?

- Foreign materials can damage processing equipment.

- Cross-contamination devalues the product.

Ask your recycler or manufacturer about collection requirements.

- Masked or demasked

- Printed or unprinted

- Maximize package density

- Labeling

- Collection supplies (gaylords, totes, pallets, etc.

PRO TIPS

- Keep polymers stored inside your facility away from saws, routers and truck dock doors to avoid cross-contamination.

- Create a wheeled pallet as a dolly to move gaylords easily, allowing them to be placed where needed for collection, then returned to the segregation area. No forklift needed!

PRO TIPS

- Keep polymers stored inside your facility away from saws, routers and truck dock doors to avoid cross-contamination.

- Create a wheeled pallet as a dolly to move gaylords easily, allowing them to be placed where needed for collection, then returned to the segregation area. No forklift needed!

Train your team on recycling … and why it matters!

- Educate your team about the program’s value to gain their buy-in.

- Identify polymers for recycling. Avoid commingling similar materials, such as PC, PETG and acrylic.

- Segregate materials based on your recycler’s requirements.

- Financial benefits of properly segregating materials.

- Detail the risks associated with contamination.

Minimize freight expense

- Discuss costs with your recycler.

- Maximize the value of your return.

- See if you qualify for prepaid freight.

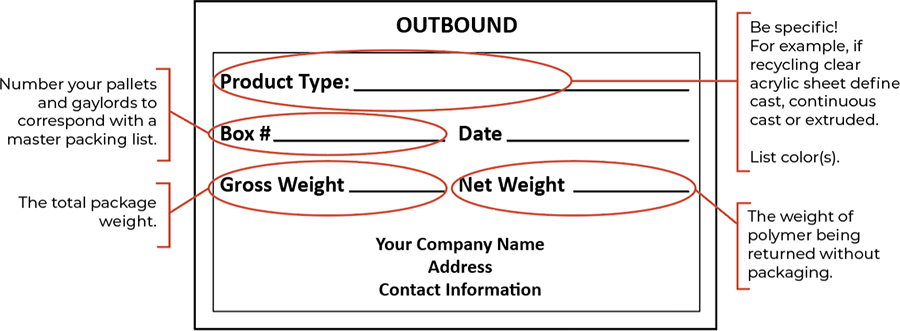

Label clearly

- Be sure the label is visible and easy to read — printed is better than handwritten.

- Include a packing list. Itemize and track this information.

What if you don’t have a local recycler?

- If your company has multiple branch locations:

- Negotiate pick-ups between locations with your recycler.

- Use internal transfers to aggregate material in a centralized location.

- Explore other options when recycling is not possible, such as Waste-to-Energy. [online tool coming soon!]

- Comingled materials

- Contaminated materials

- If creating larger drops, sell those drops to fabricators creating smaller parts or inventory for future jobs.

PRO TIPS

- Cut larger shapes and stack flat to increase package density and scrap value.

- Put a top on your gaylord to allow double stacking in the truck.

- Limit pallets to standard sizes to avoid surcharges.

- Use a bailer to compress lightweight/hollow materials and films.

- Program your router for exit cuts that minimize skeleton/trim size.

- When working with a manufacturer, ask about backhauls when receiving regular inventory to minimize freight costs.