of

Development Conference

Innovation

Performance Plastics Workforce

Program

Cover design by Mackenzie Diekmann,

IAPD Senior Multimedia & Design Manager.

FOOD & BEVERAGE

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

IAPD President

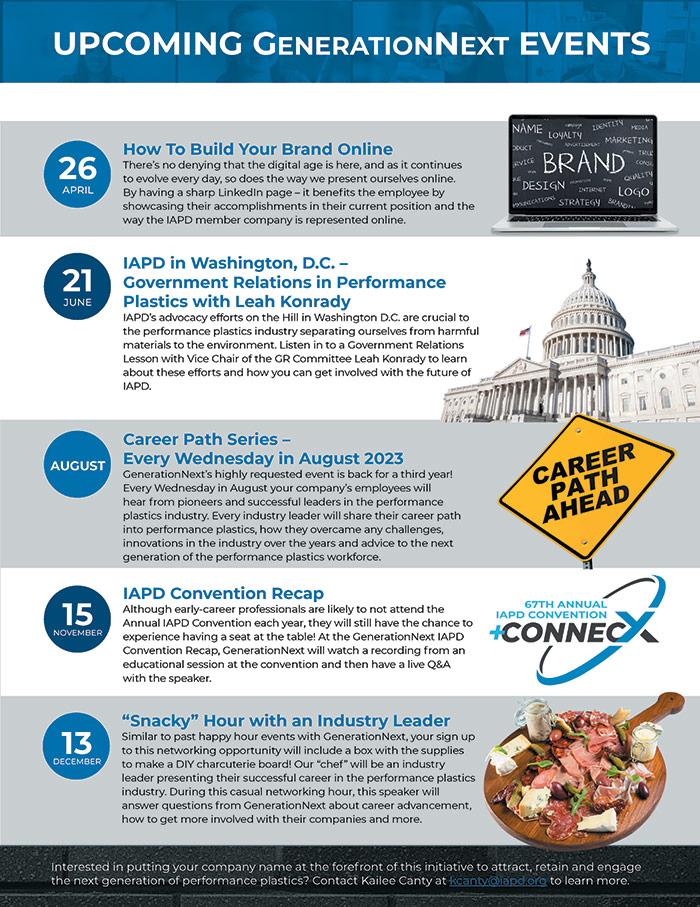

t is time again for IAPD to gather for the 2023 IAPD Leadership Development Conference. In the many years I have been blessed to be a part of the IAPD – The Performance Plastics Association, I have attended many annual conventions, committee meetings, board member orientations and Leadership Development Conferences. I have learned so much from all of these that I attended, but looking back, I really believe that the Leadership Development Conference is where I was able to learn the most. It turned out to be exactly what the name implies; a chance for all IAPD members in every aspect of the plastics industry to come together, and be given tools to help them develop into the leaders needed to carry this industry into the future.

When are most of us given an opportunity to meet with others that share the same common goals as us, with the same interests as us, and that want to do something to make a difference for ourselves, our companies and our association? When are most of us asked how we feel about topics that are meaningful enough to us that we made the decision to get involved, to join a committee to make a difference? When are most of us given an opportunity to meet with employees from our own company, sister companies, competitors or to meet vendors from the performance plastics industry? Not only to meet these people, but to be able to spend time networking with these people, spend relaxing time over a drink or a meal and having the opportunity to know these people. These are the kind of interactions that happen at the LDC, and that we will continue to have year after year, with different people and different topics. The IAPD Leadership Development Conference is a goldmine of opportunities for our industry leaders to meet one another, network and meet strategically to discuss the short and long-term solutions for what our industry is facing today.

IAPD CEO

eadership has always been a critical factor in driving success and growth in organizations. The demands placed on leaders have never been higher. Rapid technological advancements, shifting demographics, unpredictable global events, a pandemic, labor shortages, supply chain disruptions, and soon, a global recession, have created an environment that demands adaptive, empathetic and innovative leadership.

One of the key traits of successful leaders in 2023 is adaptability. The rate of change in the world today is unprecedented, and leaders who cannot quickly adapt to new circumstances will struggle to stay relevant. This requires not only a willingness to change, but also the ability to navigate complexity and uncertainty.

To be adaptable, leaders must be willing to let go of the past and embrace new ideas and approaches. They must be willing to take risks and experiment with new strategies, even if they may not initially understand the full implications of these changes. This requires a certain level of humility, as leaders must be willing to admit when they don’t have all the answers and seek input from others.

Kim Ansel has been promoted to inside sales manager based in Seattle, WA. Ansel has worked for the company for more than ten years and has continually grown her expertise and responsibilities. In her new role, she is responsible for managing inside sales representatives to achieve a business plan that includes markets, key accounts and target accounts. Her continuous contributions, ambition, and extensive knowledge of the location and plastics industry, makes her the perfect fit for the job.

Beth Gee-Knotts, a new inside sales representative, is responsible for building and maintaining relationships with customers in the Northeast Georgia area. She plans to create new business, focus on customer retention, establish post-sales relationships and follow up with clients to ensure all expectations are met. Knotts brings 13 years of plastics distribution experience to her new role and she looks forward to becoming an integral part of the ProPlas team.

Articles reporting on plastic products are prepared from information furnished by members of the IAPD and non-member magazine advertisers. The information provided is deemed reliable but is not verified. It should not be assumed that the publisher has reviewed or tested any of the products. For more information, contact companies by visiting their websites.

Eastman, provider of specialty materials, and Exolon Group have started a collaboration for the extrusion of solid sheet materials based on Eastman’s healthcare copolyester resins.

Vivak® Med

Exolon® Multi UV HX50

Made using Eastar® 6763, Vivak® Med answers the increasing demand for thermoplastic solid sheet products and meets ISO 10993/USP Class VI biocompatibility requirements. Vivak® Med solid sheets for rigid medical packaging from the Exolon Group is extruded using Eastar 6763. The product is available in thicknesses from 0.6 to 8 millimeters. “Eastar® 6763 has been the standard for decades in rigid medical packaging applications,” says Michael Burkardt, Eastman’s business development manager, specialty plastics. “For Eastman, it is crucial to team up with renowned partners like Exolon Group, who have the industry experience and expertise needed to deliver superior value to their customers.”

DURABIO™, a plant-derived bio-engineering plastic created by the Mitsubishi Chemical Group, has been adopted for the body surface (outer layer) of ZOOM L1, a cap-type water-based gel ink ballpoint pen of the design stationery brand ZOOM, a registered trademark of Tombow Pencil Co., Ltd.

DURABIO™ is a bio-engineering plastic made using the renewable plant-derived raw material isosorbide. Its use can reduce the consumption of petroleum, which is an exhaustible resource, and can also contribute to the reduction of greenhouse gases since the plant that is the source of the raw material absorbs carbon dioxide during its growth process. Due to its outstanding impact strength and durability, DURABIO™ is used in automotive exterior and interior parts and other applications. DURABIO™ is also characterized by excellent design capability. Its excellent moldability gives a frosted glass-like matte texture to the surface of ZOOM L1. Its high transparency enables a design with depth, and a silhouette that changes depending on the amount of light. These excellent characteristics have been highly evaluated, which has led to its adoption.

ZOOM L1, a cap-type water-based gel ink ballpoint pen

DURABIO™ is used on the body surface (outer layer)

The following documents outline why your company should invest in a recycling program, high-level goals and steps to either begin or improve your current program.

IAPD – the performance plastics association is thrilled to provide this resource in the 2023 April/May issue of the Performance Plastics magazine. IAPD and the Recycling Task Force are confident that members will keep this document as a reference and a guide as they navigate how to incorporate a recycling program at their location or take their current one to the next level.

ue to its inherent advantages, performance plastics are utilized in a wide range of applications in the food and beverage industry. These applications include the transport of drinking water, wastewater and chemicals. Replacing stainless steel process components such as piping, valves, filter housings and tanks with plastics, is becoming more common as the benefits of plastics become more recognized in various industries.

For example, commercial craft brewers have used plastic vessels for fermentation as an economical alternative to stainless steel. A fermenter, in regards to brewing beer, is a vessel that brewers use to convert wort into alcohol. Wort is the mixture of water and grains that has been boiled by the brewer. Fermentation is carried out by adding yeast to the wort.

Plastics have also been used in yeast recovery systems as part of the beer brewing process. Yeast from one fermentation needs to be recovered and used to manufacture the next. High density polyethylene (HDPE) has been used as a replacement for stainless steel in yeast recovery systems. HDPE is an excellent choice for this application given its material properties and advantages it offers over stainless steel.

SpecialFocus

food and beverage

he food processing industry has always used a myriad of food grade thermoplastics in order to satisfy complex application requirements, while remaining safe and detectable. Some plastics are used interchangeably, while others have special properties that cannot easily be replaced. What if many critical material properties could be fulfilled by a single material? Polyurethane elastomers are recently replacing traditional thermoplastics in food processing applications due to their low tooling costs and wide range of properties, ranging from rubber-like to plastic-like.

Traditional plastics have always been chosen based on one or two properties, at the expense of the other critical properties, leading to a shorter part life cycle, or an underwhelming application performance. A few of the key physical properties engineers must keep in mind while selecting materials for a food process are cost, detectability, chemical resistance, heat resistance and flammability, abrasion resistance, weight and rebound rate. There are plenty of other properties to consider, however these are just some of the complex application requirements a process, quality, and mechanical engineer might consider.

Until recently, the food industry has relied on a wide selection of materials, from UHMW and POM, to PP and nylon, each selected to maximize one or two properties, but forgoing other critical properties. One example of this is the commonly used ultra-high molecular weight polyethylene (UHMW-PE). UHMW-PE is a great material chosen for food processing due to its abrasion resistance, X-ray ability and its food safety capability. However, due to a low melt flow, the material often needs to be machined to create complex shapes. This increases labor costs and creates extra waste.

The smart choice for

many high abuse

application

Available in colors: Black and White

The smart choice for many high abuse application

Available in colors: Black and White

istory has shown there is one recession-proof industry that continues to show growth year after year. It exists in the U.S., Canada and Mexico, in nearly every state and province. It is reliant upon engineering and high-performing plastics, thus feeding our industry with both new developmental opportunities and a large base of legacy applications. This is the food and beverage industry.

Over the last 50 years, global meat production has increased 500% and poultry by 1,200%. In parallel, a steady rise in aquaculture to support traditional agriculture yields have delivered similar increases in output. Major brands and their manufacturing facilities have grown steadily as retailers and restaurant chains have increasingly pushed for higher quality and lower cost products, creating a pull-through market launching even more opportunities for performance plastics.

Opportunities for performance plastics within the food and beverage industry generally fit into one of three application areas:

Conveying

Processing

Filling and packaging

eeping milk products at optimal temperature is a critical concern for dairy processing. Safety and quality are both highly reliant on maintaining product holding temperatures in the narrow range of 36 to 38 °F. The industry is highly regulated, so the need for reliable compliance is a perennial concern. At the same time, in common with a wide swath of other industries, dairy processors must increasingly consider the goal of sustainability.

Secondary cooling systems using glycol, chilled water or brine loops, keep dairy foods at temperature after extraction and pasteurization, and during other periods of intermediate and final product storage, such as holding in storage tanks, or cheese maturation. Nevertheless, wise material selection is needed to prevent these systems from creating headaches of their own for process managers.

ong before industrialized food processing was helping the world to grow, mankind was challenged with preserving fresh food and water. Innovative packaging was necessary to preserve and store food for everyday life or travel. In today’s environment, when we think about packaging for the food industry, we recognize the use of polymers as our ‘go to’ solution. Let’s take a short walk back through the evolution of packaging:

In 3500 B.C. the ancient Egyptians discovered glass blowing to create containers for food and water storage.

In 105 A.D. Emperor Ts’ai Lun of the Imperial Court invented paper, the oldest example of flexible packaging.

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Polymer Industries • (256) 657-5197 • www.polymerindustries.com

Ensinger • (724) 746-6050 • www.ensingerplastics.com

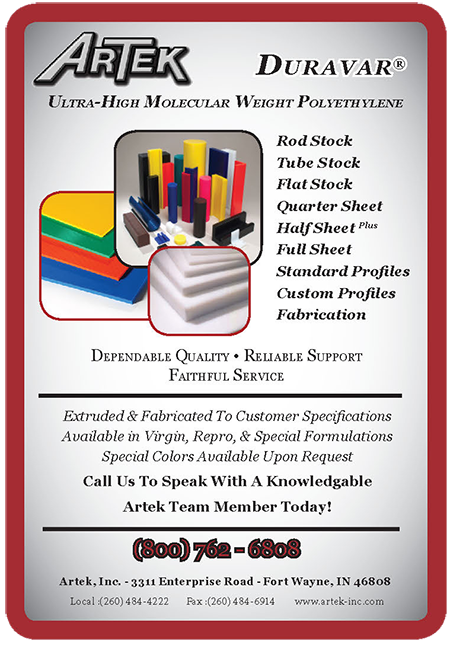

Artek, Inc. • (800) 762-6808 • www.artek-inc.com

Cast Nylons Ltd. • (800) 543-3619 • www.castnylon.com

Vortex Tool Co. • (800) 355-7708 • www.vortextool.com

Hudson Extrusions, Inc. • (800) 837-6015 • www.hudsonextrusions.com

King Plastic Corporation • (941) 493-5502 • www.kingplastic.com

Mitsubishi Chemical Group • (800) 366-0310 • www.mcam.com

BoardofDirectors

Bill Barth, Executive Committee • Piedmont Plastics • Charlotte, North Carolina, USA

Karen Brock-Amoah • SIMONA Boltaron • Newcomerstown, Ohio, USA

Jeff Burke • Curbell Plastics, Inc. • Orchard Park, New York, USA

Chris Corona • CariterWilson LLC • Solon, Ohio, USA

Peter DelGado, Vice President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Dale Delmage • Redwood Plastics and Rubber • Langley, BC, Canada

Stephen Garmon • Primex Plastics Corporation • Richmond, Indiana, USA

Hayden Hess • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Plastics • Sacramento, California, USA

Richard Miller • Braskem • Philadelphia, Pennsylvania, USA

Michael Mraz • Alro Plastics • Jackson, Michigan, USA

Deborah Ragsdale, President • Polymer Industries • Henagar, Alabama, USA

Jim Richards, Executive Committee • PLASKOLITE • Columbus, Ohio, USA

Drew Schwartz, Executive Committee • Colorado Plastic Products • Louisville, Colorado, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Publisher

Susan E. Avery, CAE

savery@iapd.org

Editor in Chief

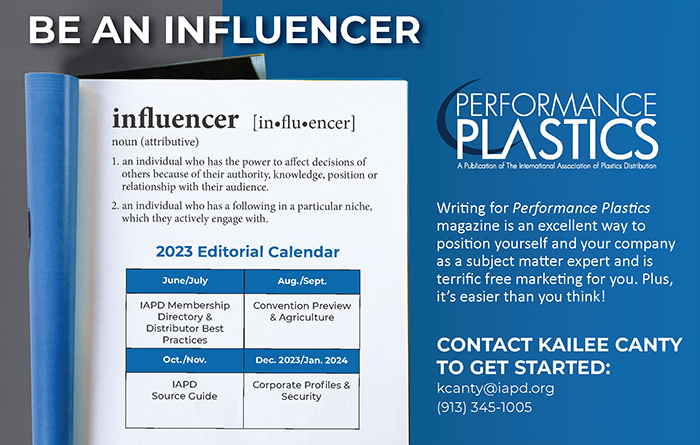

Kailee Canty

kcanty@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Chair • Courtney Kincaid • Polymershapes • Charlotte, North Carolina, USA

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Publishing

Headquarters

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE

savery@iapd.org

Editor in Chief

Kailee Canty

kcanty@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Editorial Committee

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA