There are sea-based and land-based aquaculture operations. Sea-based fish farming involves placing cages or containment structures in the ocean. Designing durable sea-based fish farming systems that do not fail is essential for sustaining a healthy fish farm as well as protecting the ecosystem. AGRU’s sea-based aquaculture solution incorporates specialized semi-finished products to help engineers create durable, long-lasting and easy-to-maintain sea-based containment systems. AGRU semi-finished products are available in PE 100-RC and more, offering durability, flexibility and chemical resistance.

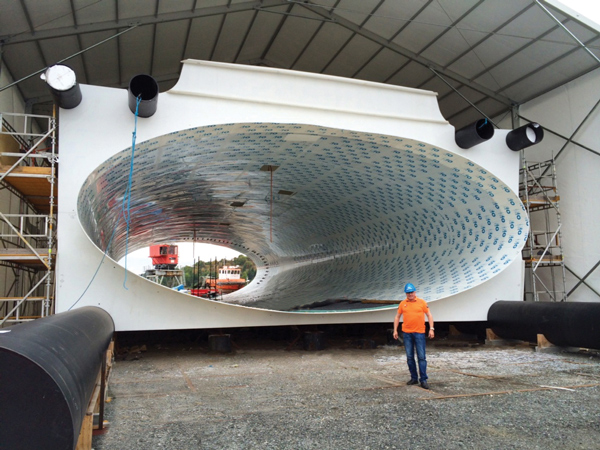

In 2014, a client sought to create a sea-based fish farm to expand their aquaculture capabilities. In this project, the client wanted to create an enclosed system using a containment tank rather than the more commonly used cage method for sea-based fish farming. Sea-based containment systems can be difficult to create, transport and maintain, especially if they are manufactured from traditional materials such as concrete or steel. Seeking a better solution, the client turned to AGRU for a solution using AGRU polyethylene sheets that were fabricated into specified dimensions for the containment system, an innovative design to construct floating sea farm structures. The sheets were made of PE 100-RC, an enhanced resin with improved strength, durability and stress crack resistance.

In 2009, a client sought to create a land-based fish farm in Smolten, Norway. The salmon and draught breeding farm would be used to raise stock that would later be transported to a sea-based system. Maintaining the health of the fish during the hatchery phase can be difficult, especially if tank conditions are poor. Seeking a better way to line their tanks, the client turned to AGRU for a land-based aquaculture solution using its CPL Sure Grip Type 560, which was fabricated into specified dimensions for easy installation. The 3 mm CPL was stabilized against ultraviolet radiation and was food grade certified. www.agruamerica.com.

The production of wind energy, on and off shore, is expected to play a major role in the transition to low-carbon energies. Tens of thousands of blades are produced around the world every year, but they are based on thermoset resins, which are difficult to recycle and are often buried or incinerated at the end of their life cycle.

When wind turbine blades made from Elium liquid thermoplastic resin reach the end of their useful life, the parts are ground and then heated to depolymerize the resin so it can be separated from the fiber filler. After purification and reformulation, a new liquid thermoplastic resin is obtained with the same characteristics as the virgin resin.

Created in 2006, the Pierre Potier Prize highlights and rewards initiatives in the field of chemistry that promote sustainable development as well as the development of eco-responsible approaches in the sector. www.arkema.com.

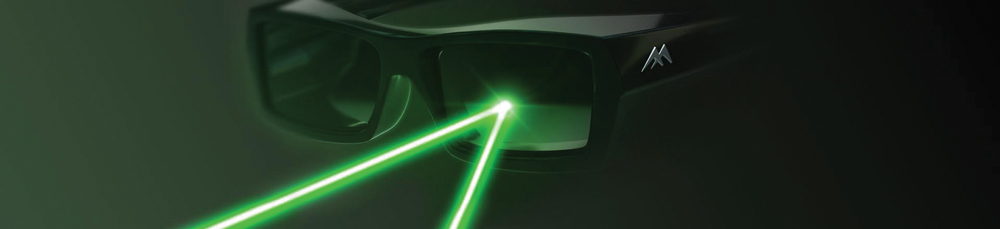

META selected Bayfol HX photopolymer film and worked with Covestro LLC – Specialty Films to customize it in order to meet three challenges:

- The raw material had to cover areas of at least 1m in width and several meters in length.

- The film and its photopolymer coating had to provide high optic diffraction and transparency, along with color-balanced red-green-blue (RGB) filtering.

- It had to retain stability when matched with other materials such as adhesives, coping with varied temperatures and humidity.

Fine-tuning the film properties in several production runs, the refined Bayfol HX120 film enabled META to design the metaAIR. In wide format web rolls with triacetate (TAC) substrate, the film can be recorded with laser light in the 440 nm to 680 nm wavelength range, achieving 99.999 percent diffraction efficiency to protect pilots from harmful laser attacks. With the volume, holographic optical element (vHOE) recorded in the film, natural color is preserved, with high transparency and stability. www.films.covestro.com.

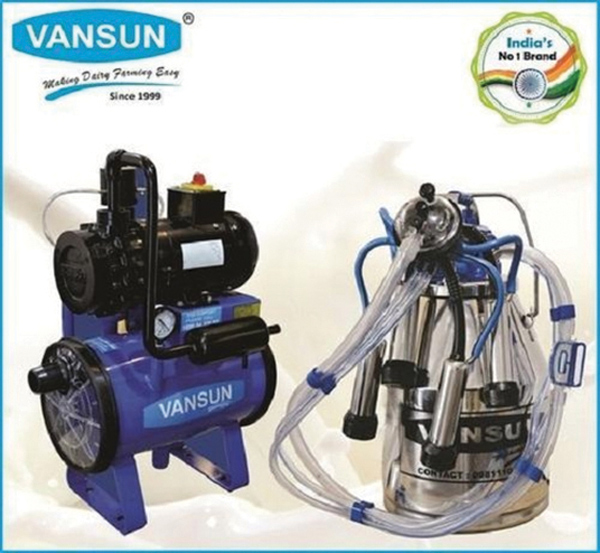

Automated milking machines work on the principle of vacuum — just like the calf suckling its mother. The vacuum applied to the teat opens the liner (milking phase) and milk flows down. Milking machines need transparent plastic material in the critical area where users want to observe the flow of milk.

In the past, Vansun used polycarbonate (PC) and polyphenylene sulfide (PPSU), but farmers complained about breakage during use and machines becoming hazy. Because cow and buffalo milk have a high fat content, the milk flowing through the machines left a residual haze that hindered transparency.

In addition, the milk machine components are subjected to cleaning in place (CIP) treatment at high temperatures of 176°F/80°C in the presence of alkaline and, sometimes, acidic solutions — which causes considerable stress that was affecting material longevity. The machines also took on a yellow tone that customers disliked.

Tritan replaced PC and PPSU in many applications with its unmatched balance of properties. Products made with Tritan are clear, durable, safe and stylish. In Tritan, Vansun found the solution to its material problems.

“The right design combined with the right polymer properties ensured the final product was liked and appreciated by our customers, and it was encouraging to get the positive feedback from them. Selecting Tritan for our product design was very appropriate,” says Sandeep Raina, director of Vansun Technologies Pvt. Ltd. India. Vansun sells automated milking machines to dairy farmers across India, and market response to Tritan has been good. www.eastman.com.

Antimicrobial plastics can be used in these applications because they inhibit the growth of microorganisms on the surface of the material which cause staining, mildew and foul odors.

In many places, vets and boarding houses choose bright and cheerful colors to make up their doggy playrooms and living areas. Multi-layer colored materials, such as Polytone® from SIMONA AMERICA Industries are used to route out fun paw print cat whisker designs. www.simona-america.com.

Representatives from the Butterfly Pavilion reached out to the plastics companies in the Denver, CO, USA area asking for bids on a device to be used for enrichment with their octopuses. Since octopuses are naturally curious, they need these kinds of activities to keep them busy. In addition, visitors enjoy seeing the octopuses interact with the devices.

Charlie Waychoff at Colorado Plastic Products jumped on the opportunity to develop the toy for the Butterfly Pavilion. “I was a biology major and octopuses are my favorite animal, so I was absolutely determined to get this project. The Butterfly Pavilion people said that mine was the most enthusiastic response to their inquiry.”

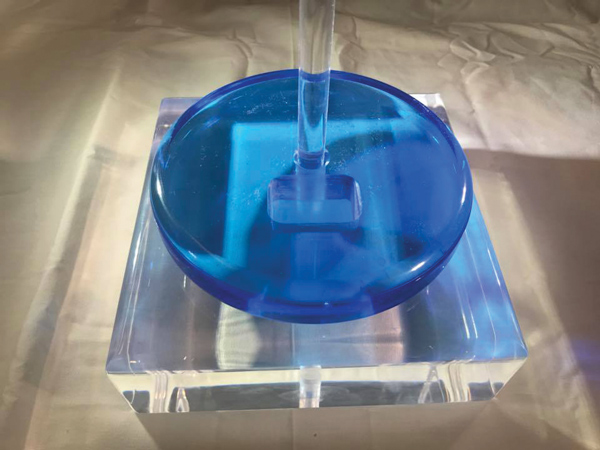

The Butterfly Pavilion did not provide too many parameters for the device, so Waychoff used his knowledge of octopuses and of performance plastics to develop an acrylic version of a rainbow stacker toy that kids might have. The largest ring, in blue acrylic, has a pocket cut out that’s large enough for the handlers to place a shrimp (a tasty treat for the octopus). They then put the other rings on top of it, and the octopus has to take off the rings to get to their treat.

Waychoff knew that he wanted to use acrylic because it’s submersible, and they didn’t want the toy to float. Since most aquariums are made from acrylic, he knew it would stand up to the salt water and octopus play. Waychoff also knew that he wanted to use bright neon colors for the toy, and that acrylic looked good in those colors. In addition, the neon colors show up well in the dim lighting in the aquarium, which mimics the natural habitat of the octopus.

“People are able to relate to octopuses in a way that is unrivaled by any other invertebrate,” noted Butterfly Pavilion aquarist Sara Stevens. “Due to their intelligence and almost childlike way in which octopuses interact with the world, our guests seem to connect and fall in love with them very easily. It’s an animal that instantly creates a sense of awe and wonder, making them fun and important ambassadors for ocean conservation.” For more information about the Butterfly Pavilion, visit http://butterflies.org.

To see a news story about the octopuses at the Butterfly Pavilion, including an octopus interacting with the toy created by Colorado Plastic Products, visit www.youtube.com/watch?v=e2CnGh3367Q.

www.coloradoplastics.com.