INDUSTRY

of

A CLOSE LOOK AT SOME INNOVATIVE COMPANIES SERVING THE PERFORMANCE PLASTICS INDUSTRY

Helping People Get (and Stay) Healthy

Lead the Way in Struggle Against Global Pandemic

for Medical Applications

Offer Second Line of Defense

in Medical Applications

For When Seeing Clearly Matters Most

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

IAPD President

s this challenging and difficult year ends, 2021 holds the promise of a vaccine for COVID-19 and, with it, the anticipation of returning to a more normal way of life. While the “new normal” may look different from our pre-pandemic lives, I’m optimistic that we will be able to refocus our attention on picking up where we left off.

When I first addressed IAPD members as your IAPD President, I shared several observations. I had just attended the K-Fair and noticed a stronger-than-ever focus on environmental sustainability and the circular economy among the exhibitors. Since European trends have a way of influencing business in North America, I was convinced that environmental sustainability would soon have to be a priority for IAPD members.

IAPD CEO

he year 2020 has been one of the most disruptive years of our lives. So much of our usual way of doing business had to change due to the COVID-19 pandemic — from “road warrior” salespeople being grounded, to getting up to speed on video conferencing, to the rise of new marketing opportunities via branded virtual backgrounds and facemasks.

Like most IAPD members, IAPD did not have a typical year, either. When lockdowns first started in March, IAPD had a full event calendar planned and was looking forward to numerous golf tournaments, regional Women in Plastics Events, the Leadership Development Conference and, of course, the Annual Convention. Staff was able to convert the Women in Plastics events to monthly virtual events, which have featured insightful speakers and enabled many more IAPD members to participate, as there was no need to travel to these events. In lieu of the opening session at the convention, IAPD presented a lively Membership Celebration video, in which we celebrated this year’s award winners, thanked our outgoing board members, welcomed our new board members and had some fun seeing so many members’ faces. If you haven’t seen the video — or you just want to see it again — visit IAPD’s YouTube channel.

“Polycarbonate sheet has natural protective properties for any number of applications,” said Jeff Bostic, vice president of the polycarbonate division of PLASKOLITE. “TUFFAK CA delivers all of those benefits as well as fire resistance, making it an ideal option for everything from decorative panels and wall and ceiling finishings, to protective coverings for artwork and other displays.”

Receivables over 30 days were 2.20 percent, up from 2.00 percent the previous month and up from 2.00 percent the same period in 2019. Charge-offs were 0.60 percent, down from 0.82 percent the previous month and up from 0.46 percent in the year-earlier period. Credit approvals totaled 72.3 percent, down from 72.9 percent in September. Total headcount for equipment finance companies was down 4.9 percent year-over-year. Separately, the Equipment Leasing and Finance Foundation’s Monthly Confidence Index (MCI-EFI) in November is 56.1, up from the October index of 55.0.

There are sea-based and land-based aquaculture operations. Sea-based fish farming involves placing cages or containment structures in the ocean. Designing durable sea-based fish farming systems that do not fail is essential for sustaining a healthy fish farm as well as protecting the ecosystem. AGRU’s sea-based aquaculture solution incorporates specialized semi-finished products to help engineers create durable, long-lasting and easy-to-maintain sea-based containment systems. AGRU semi-finished products are available in PE 100-RC and more, offering durability, flexibility and chemical resistance.

team of researchers led by Case Western Reserve University (CWRU) will investigate ways to improve how common plastics are recycled, an effort supported by a US$2.5 million grant within the U.S. Department of Energy’s (DOE) recently announced Plastics Innovation Challenge.

The Case Western Reserve-led team will work to develop and test a technique with help from government and industrial partners — one that blends the better parts of an efficient but cost-prohibitive chemical method of plastic recycling with typically high-output but low-efficiency mechanical means to “upcycle” up to 80 percent of the plastic it takes in.

Upcycling is reusing recycled material in meaningful ways, not just for items like trash bags, filler or padding, as is often the case with recycled plastics.

ven though 2020 didn’t go exactly as planned for Women in Plastics, the group was able to present one in-person event in March prior to the shutdown caused by the COVID-19 pandemic. After canceling the other in-person events for the year, the Women in Plastics leadership successfully pivoted to a virtual format. From July through December, monthly Women in Plastics virtual events featured a speaker on a relevant topic, plus the opportunity to network with other IAPD members in small breakout groups. In addition, Women in Plastics hosted three consecutive virtual happy hours on Thursday, October 1, at 5:30 p.m. Eastern, Central and Pacific times. IAPD members were welcome to attend one, two or, for the intrepid few, all of the virtual happy hours. Also new for 2020 was Watch Me WIP day on Saturday, October 3, a day for IAPD members to participate in local service projects and achieve fitness goals. Read on for more information about all of these events.

ach year the healthcare industry grows and changes in ways that we never could have imagined; this year is no exception. Performance plastics are an integral part of the growth of the industry. Performance plastics experts have been able to work with scientists and engineers to make their innovations come to life. The ability of plastic materials to be clear, flexible, lightweight, easily bondable and sterilized are a few of the many benefits that keep the healthcare industry using performance plastics. Put aside the events of the last nine months (although it feels like nine years!), and there are countless applications for performance plastics that have helped improve outcomes of medical procedures and life expectancies.

For example, consider CPAP machines, which are prescribed for people with sleep apnea, a condition in which they stop breathing while sleeping because their airways are closed or blocked. You probably either know someone who uses one or perhaps you use one yourself. These machines have helped to improve the quality of sleep for the patient (and their partner!), plus decrease their chances of heart failure and death. Virtually the entire unit is made of performance plastics including, but not limited to, silicone, polyvinyl chloride (PVC) and high-density polyethylene (HDPE).

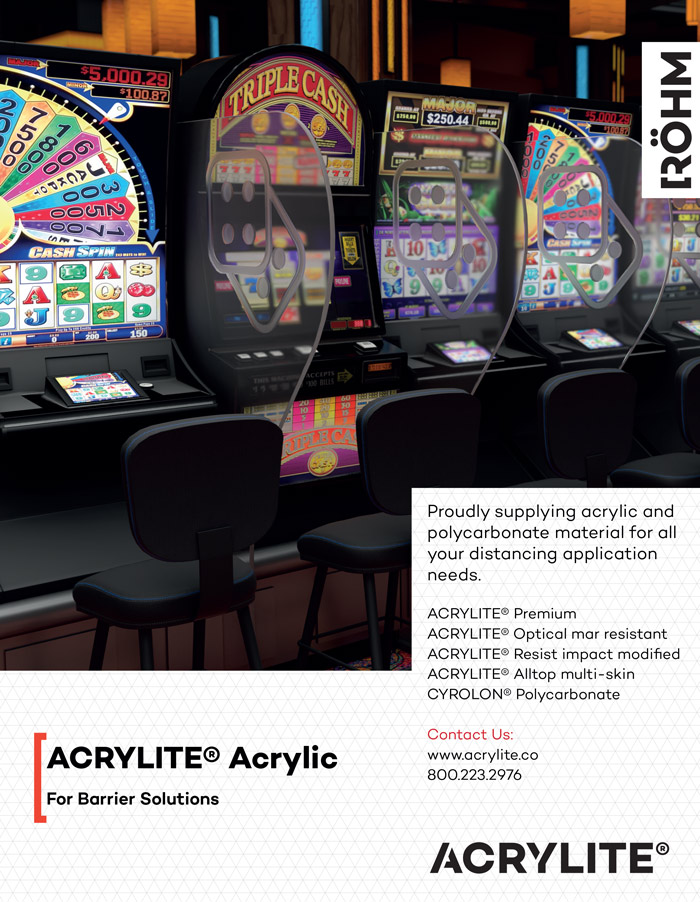

othing has demonstrated the importance of plastics in medical applications quite as clearly as the events of 2020 resulting from the global COVID-19 pandemic. The performance plastics industry was quick to mobilize and step up to meet the needed demand for personal protective equipment (PPE) such as face shields, as well as clear sheet material for barriers that helped essential businesses protect their customers and employees and safely reopening the economy. Not far behind came the need for source controlled and suitable materials such as polyetheretherketone (PEEK) and acetal copolymer (POM C) for ventilator components to care for the critically ill from the COVID-19 virus. And now, to defeat the virus through the use of vaccines and therapeutics, the pharmaceutical industry is looking to the performance plastics industry for the appropriate materials for single use processing alternatives in developing the cure.

As pharmaceutical companies are stepping up the development of cures and treatments for COVID-19 with government direction, new demand for processing equipment is increasing. Filling this demand has been supported with government directives such as Operation Warp Speed in the United States which is designed to ensure priorities are given by manufacturers to key development components in the fight against the virus. Components in direct contact with bio pharmaceutical products are typically single use to avoid cross contamination between batches. Special needs for the performance plastics filling these applications are chemical resistance to solvents commonly used in the process, low extractable potential from the materials and gamma stability, since gamma radiation is the predominant method of sterilization for these components. The materials also need to be source controlled to eliminate any variables in the ongoing manufacturing process. Some of the materials fitting these requirements are PEEK, polyphenylsulfone (PPSU), polysulfone (PSU), polyetherimide (PEI), polypropylene (PP), polycarbonate (PC) and acrylic (PMMA). Recently, a new clear material has been introduced that addresses some of the short comings of polycarbonate and acrylic, while maintaining all their key benefits.

atients expect to receive medical care in clean, warm and welcoming environments. Medical equipment manufacturers are challenged to find aesthetically pleasing materials that can withstand the high traffic and harsh disinfectants found in healthcare facilities. In order to maintain the aesthetics of medical equipment in busy workspaces, durability is imperative and high-touch surfaces require material properties such as impact strength, chemical compatibility and wear resistance.

Because of these factors, manufacturers of medical devices, diagnostic equipment and medical furniture are moving away from materials such as metal and fiberglass and toward durable thermoplastic blends. Examples include polyvinyl chloride (PVC)/polymethyl methacrylate (PMMA) and acrylonitrile-butadiene-styrene (ABS)/PVC blends that are not only easy to thermoform and fabricate, they also meet regulatory compliance and safety standards such as UL 94 Std V-0 and 5V, as well as RoHS.

he COVID-19 pandemic has shown just how vulnerable we are to microscopic threats that can cause tremendous harm worldwide. The failure to gain control of this virus has instilled fear about its long-term impacts and our ability to prevent future disease outbreaks. Fortunately, there are new technologies, strategies and products being developed and implemented today that aim to reduce the threats posed by harmful microbes such as COVID-19.

The first line of defense against the spread of coronavirus today involves practicing guidelines established by the Centers for Disease Control (CDC), National Institutes of Health (NIH), World Health Organization (WHO) and other agencies. These guidelines include disinfection, social distancing, use of personal protective equipment (PPE)/masks and handwashing. Such precautions, along with medical testing and self-quarantine of confirmed and suspected cases, are our primary methods for controlling and reducing COVID-19 transmission until an effective vaccine reaches the public.

aterials selected for medical applications such as diagnostic imaging equipment, mobile carts, hospital beds and exam room cabinetry must be clean, reliable and safe. The need for differentiation in technology and aesthetics, as well as reliable chemical resistance and durability, has led to an increase in the use of thermoplastics in medical device applications

hen it comes to the effective protection of front-line workers against pathogens, the current COVID-19 pandemic has revealed a gap in the clear-view personal protective equipment (PPE) market. Conventional face shields and other transparent safety gear often fail to ensure adequate long-term anti-fog performance, especially in facilities where high humidity and temperature fluctuations can occur. Subsequently, when seeing clearly matters the most, protective eyewear and shields may not be worn as required or must be taken off for frequent wiping, thus potentially risking the safety of users. A polycarbonate film with a special one-side anti-fog coating helps personnel in healthcare and other exposed environments maintain a clear view over longer time periods even in areas subjected to high humidity and sudden temperature changes.

Dedicated research in polymer and coating technology to overcome these constraints has resulted in a film that extends the time-to-fog under these conditions. This allows the users of visors and goggles manufactured from this film to concentrate on their jobs in the safest way without being impaired by fogging.

ince we weren’t able to get together in person this year for the Annual IAPD Convention, we wanted to find a way to celebrate our members and look back at the good 2020 has brought us. On October 28, 2020, hundreds of IAPD members gathered virtually for the IAPD Celebrating Members virtual event. This video presentation featured membership milestones, recognition of the 2020 IAPD Award winners, an introduction to the 2020-2021 IAPD Board of Directors, an address from IAPD President Craig Saunders and more.

If you missed the live event, you can view it on-demand on IAPD’s YouTube channel or by scanning the QR code below.

Medford

Priewe

“Primex offers the opportunity to fully utilize and expand my sales background and experience in the plastics industry,” said Priewe. “The wide range of leading products offered by Primex will allow me to grow the business while providing customized solutions to our customers.” According to Priewe, other things that attracted him to Primex were the company’s 50 years in business and its constant upgrades to its facilities and product lines. Prior to beginning his business career, Priewe served in the United States Marine Corps in San Diego, CA, USA.

Corporate Profiles

geared towards excellence

ith more than 45 years of experience in plastics manufacturing, Polymer Industries is proud that the quality standards they initially promised to their customers are still in place. As they grew their product portfolio, their goal was to manufacture quality products and, today, quality continues to be the cornerstone of the business.

Their capabilities include: polyolefin sheet extrusion, ram extrusion, mechanical sheet and rod extrusion, compression molding and fabrication. They strive to continuously introduce innovative products to meet the needs of customers while staying competitive in an ever-changing marketplace. Polymer Industries products include: Densetec® high density polyethylene (HDPE), polypropylene (PP), high molecular weight polyethylene (HMW), low density polyethylene (LDPE) and Polyslick ® ultra-high molecular weight (UHMW-PE). Their mechanical division produces a variety of Mechetec® high performance materials, acetals and extruded nylon. They have one of the widest ranges of polyolefins and high-performance plastics available from a single manufacturer. At Polymer Industries, innovation is a core value and an integral part of their capabilities and products.

traditionally innovative

öhm, the inventor of “acrylic glass” is the global innovation leader in methacrylate chemistry, PMMA and acrylic sheet, film, rod and tube. Invented in 1933, “acrylic glass” was polymerized in cast sheet form between glass panes and the acrylic cell cast sheet process evolved creating a global market for transparent, weatherable “acrylic glass.” This development led to innumerable creative uses for this crystal-clear transparent and brilliant new thermoplastic material that can be formed, cut, drilled, polished and converted into parts and components for applications across most industries and markets.

Röhm rapidly innovated with this new material, including chemical modifications of MMA to develop a wide variety of methacrylate monomers, dispersions and resins; polymerization processes for conversion of MMA to PMMA; and casting and extrusion processes to create new forms with different properties allowing a wider variety of uses and applications. Röhm continues to innovate in the MMA chemistry and conversion processes as demand increases throughout the world.

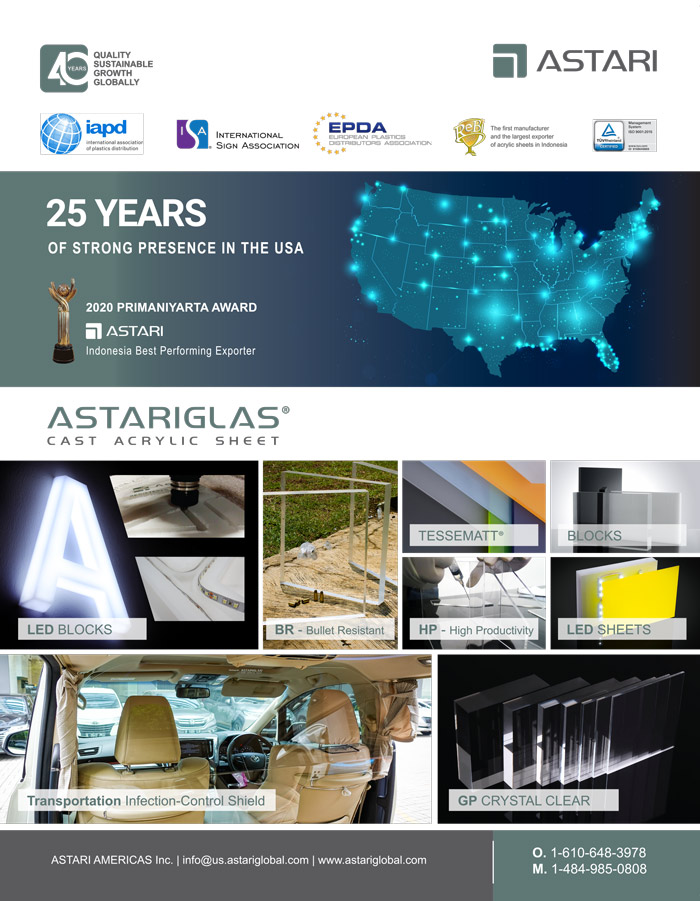

40 years of quality sustainable growth globally

s one of the largest cell-cast acrylic sheet manufacturers and a trusted supplier globally, ASTARI manufactures the world-recognized ASTARIGLAS® brand. ASTARI has been serving the U.S. market for more than 25 years with nation-wide distribution points.

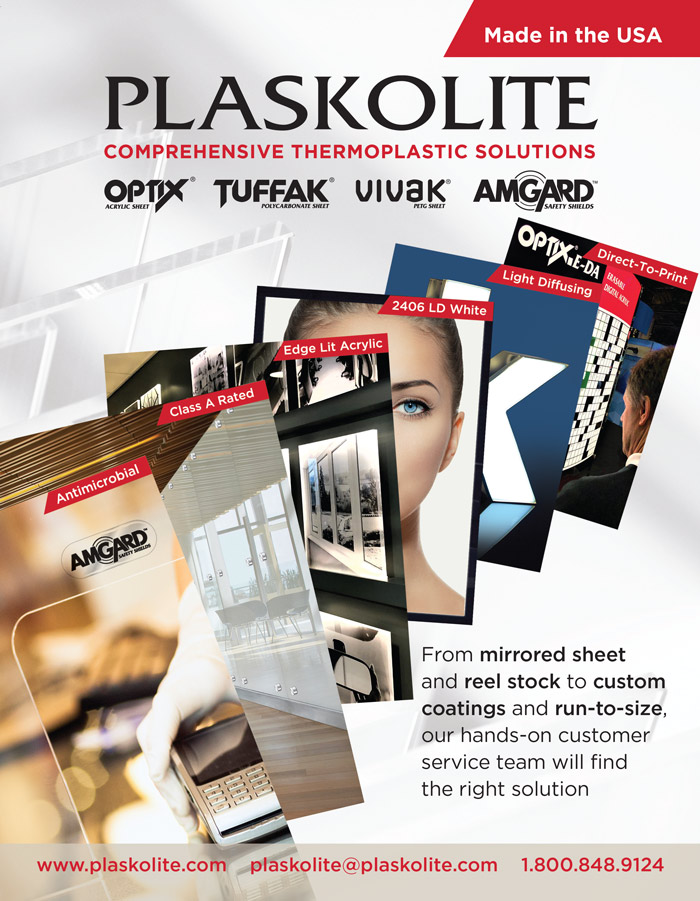

comprehensive thermoplastic solutions

LASKOLITE is North America’s leading manufacturer of acrylic sheet, polycarbonate sheet, acrylic polymers, ABS, PETG, acrylic mirror and performance enhancing hard coatings. Founded in 1950, by Donald Dunn and family, PLASKOLITE has a reputation for providing the highest quality products in the industry. PLASKOLITE’s innovative thermoplastic sheet solutions are used in a wide variety of applications, including windows, doors, lighting, signs and point-of-purchase displays.

PLASKOLITE produces superior thermoplastic solutions for customers worldwide. Headquartered in Columbus, OH, USA, PLASKOLITE operates 10 manufacturing plants: Columbus, OH; Zanesville, OH, USA; Compton, CA, USA; Olive Branch, MS, USA; Monterrey, Mexico; Memphis, TN, USA; Sheffield, MA, USA; Grand Saline, TX, USA; and Malatya, Turkey. Their Linden, NJ, USA facility excels in the development and application of high-performance lighting profiles used by most major LED lighting manufacturers.

a global leader in plastics innovation

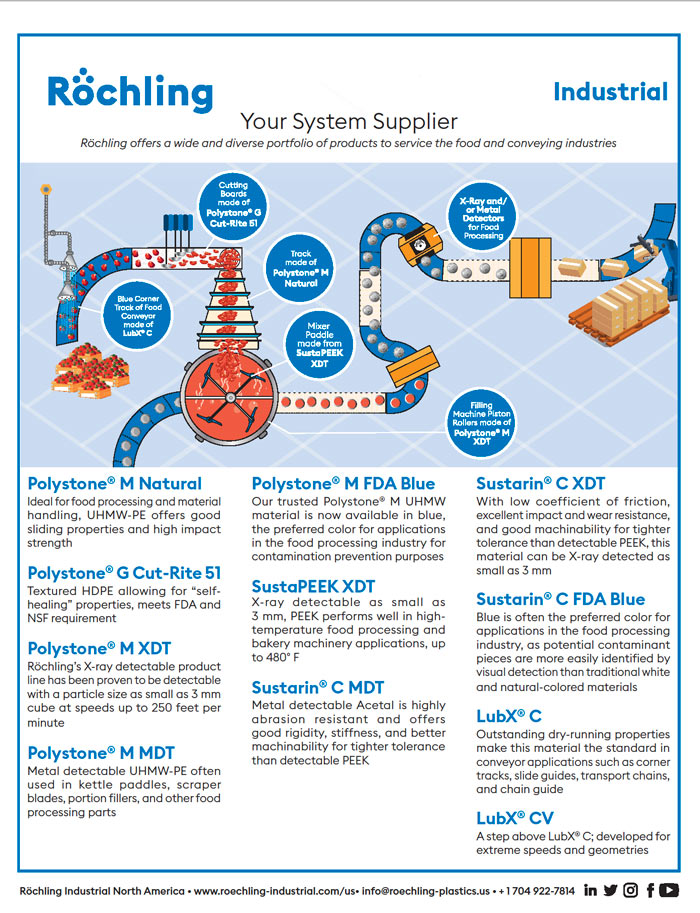

he Röchling Group, made up of industrial, medical and automotive divisions, employs nearly 11,000 worldwide at 90 locations in 25 countries. Backed by a global network, Röchling Industrial North America is one of the world’s leading manufacturers of high-quality semi-finished thermoplastics, engineering products and composites. Featuring what they believe to be the most comprehensive product line within the United States and Canada, Röchling is committed to developing efficient, innovative and sustainable solutions for their customers.

Through continuous investments and improvements in new manufacturing technologies, Röchling products are used and specified by engineers and cater to a wide range of industries.

industry leader in engineering thermoplastic stock shapes

ecognized as a worldwide leader in plastics processing technology and application development, Ensinger has the ability to combine the optimum material solution with the most suitable manufacturing method, and thus provides the industry with the most innovative and cost-effective engineering solutions available today. Ensinger designs and manufactures semi-finished and finished products tailored exactly to the customer’s individual requirements. Your projects can benefit from Ensinger’s vast knowledge base and many years of experience in finding the best solutions for problems involving engineering thermoplastic materials.

Ensinger offers a broader array of engineering materials than any other plastics processor. From general industrial materials such as polypropylene, polyethylene, acetal and nylon to high performance resins such as TECAPEEK® polyetheretherketone and TECATRON® polyphenylene sulfide, Ensinger has the ability to provide shapes and parts for even the most difficult and challenging applications and environments.

excellence in innovation, design and production for worldwide markets

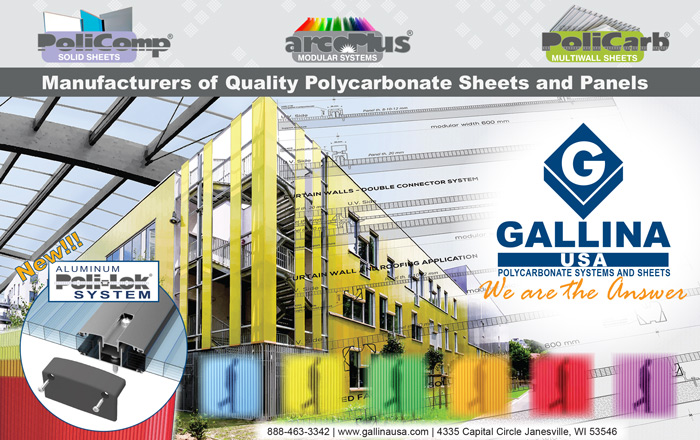

ott.Gallina Srl was founded in 1960 in La Loggia, Italy thanks to Dr. Pier Aulo Gallina’s entrepreneurial spirit. Dr. Gallina’s ingenuity and love of automobiles provided the impetus to produce and supply profiles for the automotive industry. This industry development provided the foundation for decades of growth in the production of polycarbonate sheets and systems throughout Europe, North and South America and the Middle East.

Today the company is a renowned player in the production of sheets and polycarbonate systems used for windows, roofing and vertical façades for the construction industry. With plants in Italy, United States, Greece, Turkey, India and Germany; along with offices in Spain, France, Germany, Belgium, Sweden, United Kingdom, United Emirates, Morocco and Colombia, Dott.Gallina represents excellence in innovation, design and production for worldwide markets.

panel processing technology

or almost 70 years, Hendrick has been the foremost innovator in panel processing and machining. Their commitment to quality is evident in their entire product line of horizontal saws, vertical saws and CNC routers. No matter what your production requirements are, Hendrick is up to the task.

As we enter the New Year, Hendrick is thrilled to announce the recent launch of several new product lines including the HK5 Series Computerized Panel Saws, SPN Series Vertical Beam Saws, the HM3 Automatic Beam Saw and HSR Series CNC routers. These lines are superior to their predecessors, with innovative features and precision components. If you have been thinking about upgrading your machinery, now is the time to do it with Hendrick as your trusted partner.

committed to quality and continuous improvements

ince their inception over 50 years ago, Hudson Extrusions, Inc. has been dedicated to a singular goal: “Total Customer Satisfaction.” They strive to exceed their customers’ expectations through outstanding customer service, quick turnaround times and producing extruded plastic tubing and profiles of exceptional quality.

Having been family owned and operated since 1956, they value the personal service that has become scarce in today’s technologically advanced environment. Their knowledgeable sales staff has a combined 40+ years of experience in the plastics industry and are ready to help with any questions or inquiries you may have.

Our Innovation. Your Imagination.®

ing Plastic Corporation is a leading manufacturer of quality polymer sheets, slabs and massive shapes — including several products pioneered by the company. Its polymers are made in the United States and sold worldwide through a network of top plastics distributors to customers who fabricate products for the marine industry (King StarBoard® brand), signage, food service, healthcare, architectural, industrial and other markets.

machines built for a lifetime

omo Machine, Inc. designs, manufactures and supports an entire line of high quality precision CNC machining centers in Lakewood, NJ, USA. A wholly owned subsidiary of PMC Global, Inc., KOMO is now one of the largest manufacturers of CNC routers with several thousand installations worldwide.

For more than 50 years, KOMO has been driving the changes and setting higher standards of performance industry wide. KOMO has built an organization that continues to define the cutting edge, from hardware to integrated software, all while maintaining the superior customer support for which the KOMO name has become synonymous.

thermoset prepregs | sheets | shapes

orplex-Micarta is a leading manufacturer of high performance thermoset composite materials based on impregnation and lamination technology. Norplex-Micarta manufactures the highest quality specialty sheet products, prepregs, rods, molded shapes and tubes to meet demanding applications around the world. The global headquarters of Norplex-Micarta is located in Postville, Iowa, USA. To support the demand for thermoset composite materials worldwide, the company also operates a facility in Changzhou, Jiangsu, P.R. China.

With a history dating back over a century, Norplex-Micarta has made significant innovations in thermoset laminate materials. Not only suppling the world with industry standard materials (NEMA, ASTM, MIL and IEC), Norplex-Micarta’s engineering staff has designed composites for specific markets. Norplex-Micarta materials can be found in aerospace, oil and gas, rail and mass transit, power generation and many other markets.

delivering creative thermoplastic solutions to today’s challenges

ince the company’s inception, Palram’s mission as a manufacturer has been to consistently push thermoplastics beyond their limits to innovate cutting-edge solutions to market challenges as they emerge.

Today, Palram is staying true to their mission by now offering the industry’s largest selection of antimicrobial thermoplastic products — the HYG series. These antimicrobial sheets are infused with silver ions to protect their surfaces from the growth of bacteria, molds and mildew that cause stains and odors. Palram’s antimicrobial HYG products are already being used within healthcare suites and hospitals, schools, locker rooms and gyms, daycare, offices and manufacturing facilities.

Palram’s HYG series of sheets are phthalate free, nonflammable, 100 percent recyclable, easy to form and fabricate, impact and chemical resistant and are printable while maintaining their full antimicrobial properties that are actively protecting the sheet’s surface.

POLYCARBONATE STRUCTURED SHEETS AND ACCESSORIES | POLYCARBONATE, ACRYLIC and PETG SOLID SHEETS

lazit-Polygal is a pioneer and world leader in the design, development and manufacturing of thermoplastic sheets and profiles. Their products are used worldwide in a broad range of markets and applications. By bridging innovation, quality and service as their cornerstone for success, Plazit-Polygal continually provides products known worldwide for outstanding durability, strength, light transmission, specialty coatings, ease of installation and superior quality. These products provide optimal performance and solutions for walkways, canopies, pool coverings, skylights, roof systems, clerestories commercial and residential greenhouses, interior design, P-O-P displays, signage, window glazing and much more.

Plazit-Polygal has earned an industry-wide reputation for uncompromising quality and innovation and is certified for ISO 9001:2000 and ISO 14001 as well as other international engineering standards such as CSTB (France), BBA (UK), B1 (Germany) and numerous others. With product development and technical support throughout the world, Plazit-Polygal is dedicated to offering world-class customer service, ensuring the company’s ability to maintain their competitive edge on the market.

one-stop shop for plastic sheet extrusion

owmark LLC is a custom extrusion company that offers its own proprietary line of engraving sheet stock. The company has been extruding custom sheet products at their manufacturing facility in Findlay, OH, USA since 1986, with more than 5,000 different stock SKUs available. This year the company added a 60,000 square foot warehouse that houses more than 5,000,000 square feet of sheet material to quickly serve its customers. The company also has additional stocking warehouses in Sparks, NV, USA and Burnsville, MN, USA.

Amarillo, Texas, USA

the high performance coating company

ciCron Technologies Limited, LLC specializes in top quality, high performance coatings for plastics. For more than 20 years, the industry leader has produced a wide range of superior coated plastic products. Whether you need sheets, film or parts, the experts at SciCron can help.

Archbald, Pennsylvania; Newcomerstown, Ohio; Findlay, Ohio USA

THREE MANUFACTURING SITES IN NORTH AMERICA OFFER A DIVERSE RANGE OF PRODUCTS AND SERVICES TO DISTRIBUTORS

IMONA AMERICA GROUP consists of three independent manufacturing and sales facilities: SIMONA AMERICA Industries, SIMONA Boltaron and SIMONA PMC.

Grand Rapids, Michigan, USA

advanced manufacturing solutions

s the industry’s leading provider of advanced manufacturing solutions, Stiles has been helping plastic manufacturers throughout North America increase their efficiency and productivity for more than 50 years. With world-class machinery backed by the nation’s largest team of field service technicians and support specialists, an extensive inventory of ready-to-ship parts and the industry’s only nationally accredited workforce development program, Stiles is your solution for any challenge and your partner in every success.

Burr Ridge, Illinois, USA

the plastic welding experts

egener Welding, LLC is an international supplier of high-quality welding, processing and testing equipment for thermoplastic materials. Their mission is not only to offer a wide range of quality products, but to ensure that their customers have access to customized solutions, expert advice, training programs and reliable service and support. A dedicated team of knowledgeable personnel are available to aid in defining the proper equipment for the job at hand as well as finding solutions to any welding problems the customer may have with customized machinery.

In 2006, Wegener Welding, LLC emerged as a new entity out of what was formerly known to the industry as Wegener North America, Inc., which had served the market with the Wegener range of primarily sheet-related thermoplastic welding and fabrication products since the early 1980s. The product lines of their partners Wegener International GmbH, Hürner Schweisstechnik GmbH and Buckleys (UVRAL) Ltd. form a comprehensive source of plastic welding and testing equipment unique to the industry.