“Polycarbonate sheet has natural protective properties for any number of applications,” said Jeff Bostic, vice president of the polycarbonate division of PLASKOLITE. “TUFFAK CA delivers all of those benefits as well as fire resistance, making it an ideal option for everything from decorative panels and wall and ceiling finishings, to protective coverings for artwork and other displays.”

TUFFAK CA sheet is offered with a five-year limited product warranty against breakage. It adds to the TUFFAK polycarbonate sheet portfolio used in safety shields, signage, face shields, mass transportation windows, skylights, forced entry and ballistic glazing, as well as many other applications requiring a combination of strength and clarity. www.plaskolite.com.

The materials used in optical components for automotive headlamps, high-power floodlights or road lighting are usually subject to high standards. However, new trends in product design increase the thermal requirements on the materials.

Increased heat deflection temperature is synonymous with loss of optical quality, even if such a loss is minimal. ACRYLITE Optical HT combines increased heat deflection temperature with excellent optical properties in one product.

“ACRYLITE Optical HT was designed specifically for applications where high-performance LEDs are used,” said Dr. Rüdiger Carloff, project manager at Röhm, who has managed the product development. “It can resist temperatures up to 221°F/105°C. This is confirmed by the RTI rating according to the UL 746B standard. It is also suitable for lighting guides with extended light paths.”

Dr. René Kogler, head of product management for lighting, extrusion and optics at Röhm added, “We responded to the market’s demand for higher heat deflection temperature of optics to provide greater design flexibility for luminaires with ACRYLITE Optical HT. 15°C increase in continuous service temperature compared to the current standard. This opens new doors in luminaire design without loss of clarity and transmittance. Customers can continue to rely on the established ACRYLITE properties such as high UV and weather resistance as well as recyclability.” www.roehm.com.

Kynar Flex 3030-50 resin maintains the same properties as other Kynar PVDF resins including high flexibility, good smoke and flame resistance, UV stability and excellent chemical resistance. While its low viscosity counterparts offer low temperature cold bend performance down to -40°F/-40°C, Kynar Flex 3030-50 PVDF maintains this cold bend performance at an even lower temperature of -76°F/-60°C. Cold temperature impact performance is also improved in the Kynar Flex 3030-50 resin. Additionally, the higher molecular weight of the material allows for more efficient cross-linking, which can raise the continuous use temperature from 302°F/150°C up to 347°F/175°C. Applications for Kynar Flex 3030-50 PVDF include cross-linked automotive cable, downhole cable, automotive fuel lines and industrial hoses. Kynar Flex 3030-50 PVDF is complementary to the lower viscosity Kynar Flex 3030-10 and Kynar Flex 3030-15 resin grades. www.arkema.com.

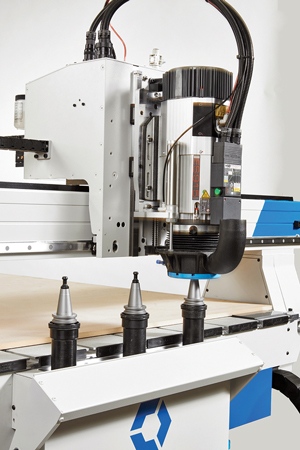

The AXYZ Innovator is available in two standard sizes: 4′ x 4′ (1.2 m x 1.2 m) and 5′ x 8′ (1.5 m x 2.4 m), with a gantry clearance of 6″ (152mm). Compact in size, the machine is powerful enough to cut aluminum, plastics and hardwoods, creating higher quality finishes and short lead times.

Popular industries and benefits include:

- Educational institutions — a new curriculum option is offered for basic CNC training

- Sign and graphics shops — easily processes 2D/3D signs in woods, metals and plastics

- Prototyping shops — takes the guesswork out of projects with simple prototyping jobs

- A heavy-duty frame with cast gantry legs for added rigidity

- Integrated servo motors replacing stepper servos for smoother motion and higher speeds

- Premium helical racks offering a new level of cut quality

- Designed to be more easily upgradable for option installations in the future

The Innovator comes standard with option ready installation packages so you can grow your machine along with your business. The exclusive three-position tool changer, available for the first time for all Innovator machines, saves time by keeping the machine running continuously without the need for operator input. At the same time, the automated cover protects the toolholders from getting contaminated, reducing maintenance and downtime. www.cncshop.com.

Existing deep ocean design literature stressed the importance of considering high hydrostatic pressure when choosing materials for deep water applications, but there was a lack of scientific research showing how plastics and composites performed in those conditions.

This paper delivers the engineering details of how polymers behave in deep ocean environments. For this study, Röchling Industrial immersed 13 thermoplastics and seven composites in pressurized artificial seawater. The plastics and composites were then tested to determine how this environment changed their mechanical properties. https://info.curbellplastics.com/deep-ocean-submersion-research.