atients expect to receive medical care in clean, warm and welcoming environments. Medical equipment manufacturers are challenged to find aesthetically pleasing materials that can withstand the high traffic and harsh disinfectants found in healthcare facilities. In order to maintain the aesthetics of medical equipment in busy workspaces, durability is imperative and high-touch surfaces require material properties such as impact strength, chemical compatibility and wear resistance.

Because of these factors, manufacturers of medical devices, diagnostic equipment and medical furniture are moving away from materials such as metal and fiberglass and toward durable thermoplastic blends. Examples include polyvinyl chloride (PVC)/polymethyl methacrylate (PMMA) and acrylonitrile-butadiene-styrene (ABS)/PVC blends that are not only easy to thermoform and fabricate, they also meet regulatory compliance and safety standards such as UL 94 Std V-0 and 5V, as well as RoHS.

Polymer blends such as PVC/PMMA and ABS/PVC have been shown to meet or exceed the test requirements for evaluating the resistance of plastics to chemical reagents. PVC/PMMA and ABS/PVC thermoplastic blends do not craze or discolor when exposed to a wide range of cleaners and disinfectants. For the high-touch surfaces in medical environments that require frequent cleaning such as mobile carts, patient headwall systems, overbed tables, stretchers and patient beds, these materials offer a significant performance advantage.

PVC/PMMA and ABS/PVC thermoplastic sheets can be formed to deep draws, resulting in fewer rejected parts. For applications that require enhanced strength and stiffness, support ribs can be formed into the material during the thermoforming process.

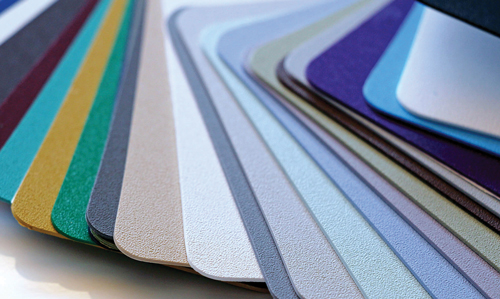

PVC/PMMA and ABS/PVC blends are offered in a wide range of colors, textures and finishes. A metallic palette mimics the look of traditional metal housings. Pearlescent and woodgrain options are also available. These materials have a number of different texture options and normally have low minimum production quantities for custom colors. They are also easy to decorate via screen printing as well as other printing methods.

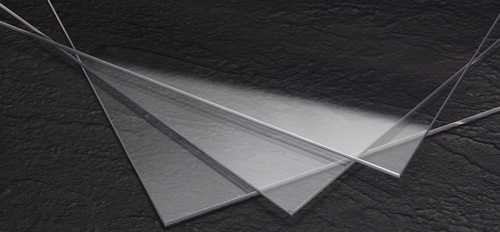

As more medical facilities incorporate protective barriers and partitions into their interior designs, transparent plastics will help to prevent microbial spread while enhancing the aesthetics of interior spaces. As medical equipment manufacturers evaluate their product lines in these rapidly evolving times, antimicrobial acrylic and polycarbonate are likely to see increasing use in medical care facilities.