ince the early 1970s, cast nylon 6 has been recognized as a qualifying substitute for metals. Mechanical engineers were initially astonished by the performance of this thermoplastic material’s performance and started using it as a substitute for cast iron, steel and aluminum. Significantly lighter than steel, approximately 1/7th its specific weight and 30 percent lighter than aluminum, cast nylon 6 offers a multitude of advantages and is used in a variety of ways.

Following the advancement of the casting process, cast nylon 6 can be molded into various shapes and wall thicknesses thar are not possible with traditional extrusion or injection molding technology. Through the implementation of various additives, the properties of the cast nylon material can be designed for specific applications. This versatility makes cast nylon 6 an excellent choice for industrial usage.

Originally used as a bearing material, cast nylon is now an industrial favorite for a wide variety of applications. From bushings and wear pads to heavy loaded sheaves for steel ropes, numerous applications are possible.

Extrusion or injection molding processes do not offer this flexibility in sizes, geometries or cycle times. This enables cast nylon 6 to be used more cost effectively than other polymer materials.

In addition, cast nylon 6 does not corrode and has good chemical resistance, which is a huge advantage over most metals.

Cranes

A cable crane carying a 25 ton payload with a concrete bucket during the construction of the Three Gorges Dam in China (www.lcs-cablecranes.com/en/projekt/three-gorges-dam/) operated with sheaves with a diameter of 1.5 meter made from nylon while the wire rope span for more than 1 mile over the Yangtze River.

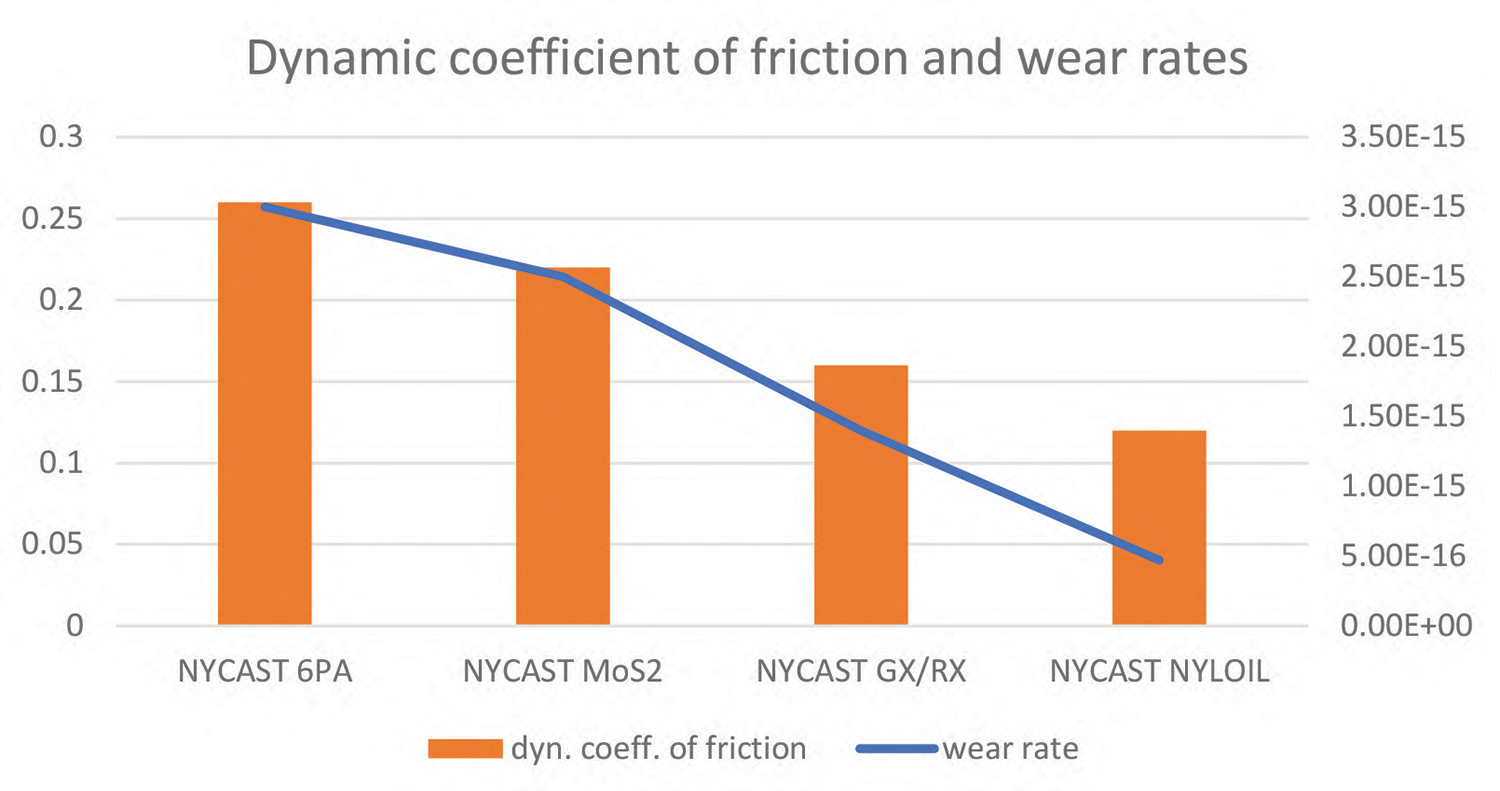

The chemical makeup of cast nylon 6 allows for customization for specific applications. For example, wear pads for telescopic cranes made from cast nylon 6 material are infused with solid or liquid lubricants to enhance the coefficient of friction and ultimately its wear rate. Using lubricant-infused cast nylon instead of bronze bushings provides for smoother operating without the use of additional grease.

Pile driving

A valve assembly in the oil and gas industry.

The concrete pillions of Pier 55 (aka Little Island) in New York, NY, USA were piled into the rock bed of the Hudson River with pile hammering equipment. Each concrete tube is 132 feet long and weighs 80 tons (176,000 pounds). There are 270 concrete tubes piled into the Hudson River to support the new island. Visit https://littleisland.org/design-construction/ to see a video about the design and construction of Little Island.

Cushion pads made from rubber-nfused cast nylon were used in the piling equipment and ensured that the process went smoothly and the piles were not damaged.

Oil and gas

In the oil and gas industry, cast nylon 6 is being used as backup rings in valves. The material must withstand high pressure and maintain its form under load. The strength the cast nylon 6 allows for use in huge valve systems.

Additional applications include:

- Pipe in pipe spacers (centralizers)

- Bundle clamps

- Riser clamps

- ROV thruster nozzles

- Sheaves for launch and recovery systems

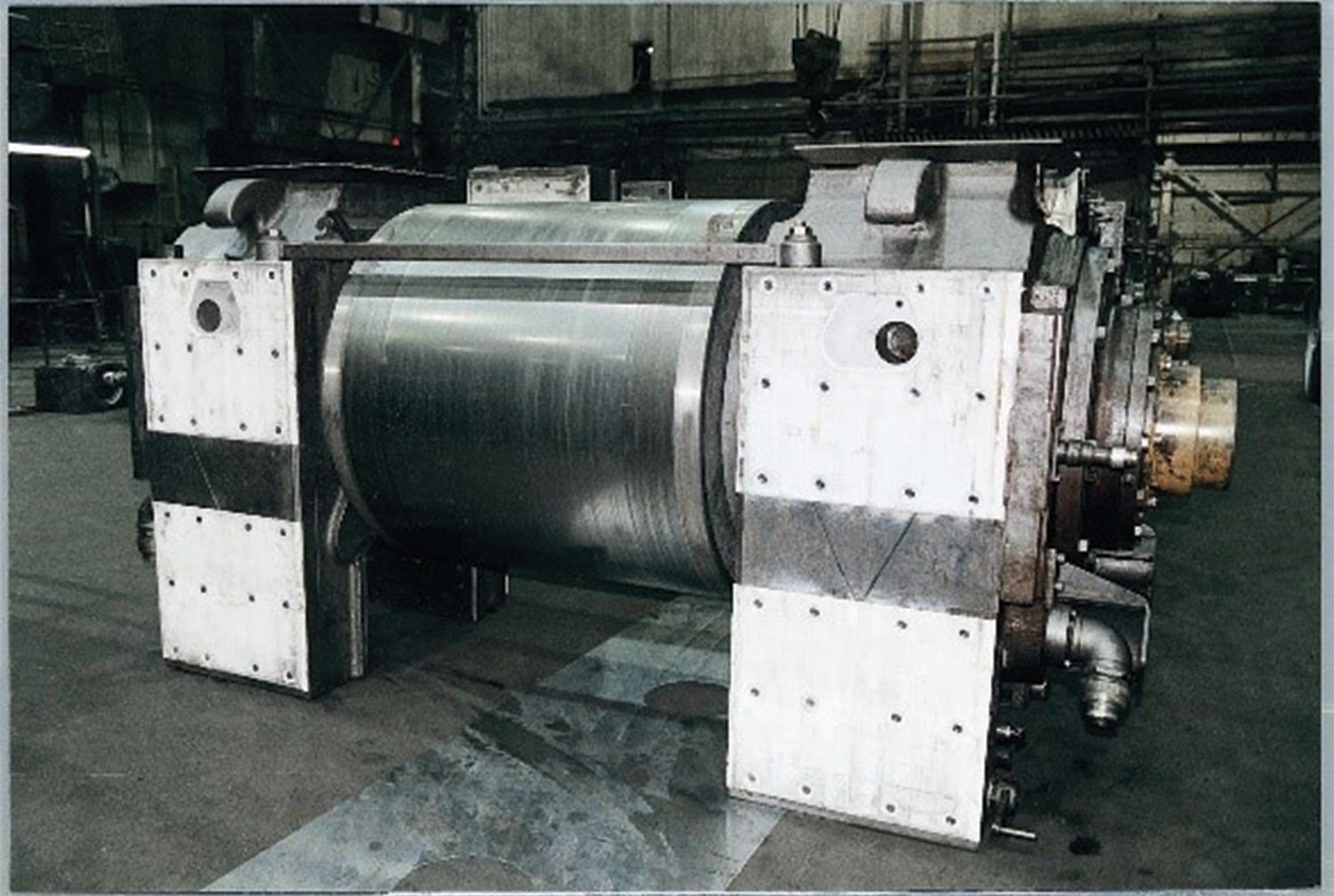

Steel mills

- Friction bearings made from oil infused cast nylon 6 to support the spindles in the stands.

- High impact resistant grades are used in universal spindles as slipper pads, acting as the defined breaking mechanism to ensure costly spindles weren’t harmed.

- Wear plates replacing stainless steel or bronze are used for outer plates in roll assemblies.

The use of special lubricated cast nylon requires less grease in applications, which is a significant environmental improvement.

Due to its dampening factor, cast nylon 6 has been used to reduce noise in various applications.

Cast nylon 6 is fully recyclable. It can be granulated and added to extrusion or injection molding process at a certain percentage. Due to its general UV stability, the material does not degrade over time.

Cast nylon 6 is also used in direct food contact and due to its high abrasion resistant you will find no particles in food if used correctly.