of

Water Solution for the World

Tampa, FL, USA

SPECIAL ADVERTISING SUPPLEMENT

A CLOSE LOOK AT SOME INNOVATIVE COMPANIES SERVING THE PERFORMANCE PLASTICS INDUSTRY

HEAVY EQUIPMENT

Cover photo courtesy of Mitsubishi Chemical Group — Engineered Shapes & Solutions.

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

Working together for success

IAPD President

s 2022 winds down, I’ve found myself reflecting on the events of the past year and starting to get excited about the year to come. This year has been characterized by a great deal of change in the association leadership and the performance plastics industry, but I can see us being stronger than ever, thanks to our relationships within the industry. These relationships are due, in part, to the dedication and commitment of members like you, the committee volunteers who do so much for the association and those who have stepped up to become members of the IAPD Board of Directors.

This upheaval means that, rather than stepping down as president at the convention in Tampa, I have been asked to serve a second term and will hand the proverbial baton to Peter DelGado, Curbell Plastics, Inc., at the convention in San Diego, CA, USA, in October 2023. I am looking forward to another year as president and feel that we can do anything if we all work together as a team. My speech at the convention in Tampa was titled “United We Stand,” and I truly believe that if we work together, we can overcome the many great challenges to the industry. Having strong relationships and trust in each other goes a long way toward allowing us to be united when faced with the issues so many of us contend with every day, such as labor challenges, industry reputation, legislative threats, the list goes on.

Editor’sPerspective

IAPD CEO

n her President’s Message in this issue, Deborah Ragsdale describes the changes to IAPD leadership this year. IAPD’s governance model is designed to accommodate the unexpected and ensure continuity in leadership. Our ability to weather the changes and attract new members to the board confirms two of my beliefs when it comes to association governance: First, trust the process. In this case, the process resulted in new board members who each bring excellent experience, insight and vision to the role, from member companies who have not engaged at the board level in the past. Second, I believe that the right leaders are in the right place at the right time. Each association president brings different strengths and skills to the position. Somehow, it always is the exact combination that we need at that given time.

Deborah has brought absolute optimism and incredible relationships with the distributors in this industry to the position. When we needed distributors to put people forward to the board, they responded to her. Peter Delgado, our current Vice President, after serving two terms on the board previously, stepped right into the VP position when asked. I can’t wait to see what Peter will do as president of IAPD.

Resin manufacturing facilities are not often described as a labor of love, but with a story rooted in family history and dedication to the community, it is fitting for ResinTech’s plant in Camden, NJ, USA. The 360,000-square-foot project houses the company’s global headquarters and production facilities. Throughout the 175,000-square-foot cation resin manufacturing facility, a variety of chemicals, acids and other caustic materials crisscross overhead, enclosed safely with Corzan® CPVC piping, chosen for its reliability in harsh conditions, long-term performance and affordable installation.

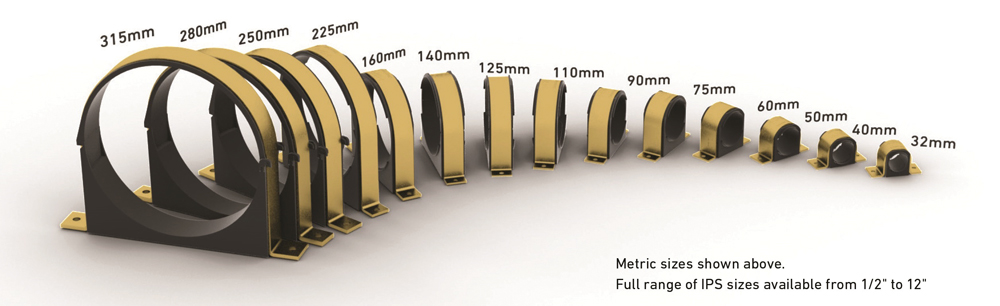

Traditional pipe clamps hold piping in a fixed location. If plastic pipes are held in place too tightly without allowance for thermal expansion, mechanical stress is transferred to the pipe. Stress of this kind on plastic pipes is the leading cause of premature piping leaks and failures. When plastic piping leaks, it is usually near clamping locations.

ew Life International, a non-profit organization based in Underwood, IN, USA, has provided safe water to communities around the world with a cost-effective and simple-to-operate water purification system since 1998.

New Life’s President Duvon McGuire learned the risks of unsafe water as a child. While serving in Ecuador with his missionary family, he contracted a nearly fatal infection from contaminated water. Motivated to study pre-med and chemistry in college, McGuire eventually traveled to India, working in hospitals and witnessing firsthand the health perils and needless deaths resulting from unsafe water.

Through years of research and experimentation, McGuire invented an affordable, lightweight and portable water purifier that can disinfect large amounts of water quickly for entire communities. Since 1998, thousands of recipients in more than 80 countries have received these purifiers, providing safe water to individuals, schools, hospitals and entire communities. The ongoing development and distribution of the water purifiers is managed through New Life International.

Review

n 2022 we brought Women in Plastics back with a bang from the hiatus of the pandemic. You wouldn’t be able to tell that we ever skipped a beat – Women in Plastics continues to be the most engaging and enriching program for women in the performance plastics industry.

Three in-person Women in Plastics workshops were held in 2022: an event on April 6, 2022, in Houston, TX, USA with a total of 48 attendees, a workshop in conjunction with the Leadership Development Conference in Charlotte, NC, USA with 84 attendees and lastly – but certainly not least, the Pittsburgh, PA, USA workshop with 69 attendees.

Year in

Review

ccording to Dale Delmage of Redwood Plastics and Rubber and Board Liaison to the GenerationNext group:

I am excited to be the new Board liaison for the IAPD GenerationNext. This group was established with the following goals in mind, to:

- Create a forum where young professionals can network to share ideas and experiences

- Align topics important to young professionals with IAPD’s vision for the future

- Promote IAPD’s Member companies’ career opportunities to young professionals

- Share experiences and insight from seasoned members with young professionals

- Have fun connecting with peers and industry leaders

Heavy Equipment

by Dr. Ted Trautman, PLASKOLITE

perator safety is paramount on the job site when operating heavy equipment. Heavy equipment cabs are purposely designed with clear lines of sight for manipulating machinery in taxing work environments. High optics and low distortion are critical for working long hours, but high visibility cannot trump operator safety. When hazards such as tree limbs, rocks and projectiles from equipment failure are present, impact-resistant glazing is a critical for protecting operators.

Polycarbonate (PC) sheet offers high impact resistance, low distortion and high clarity, making it the material of choice for window glazing in heavy equipment applications such as forestry, construction, agricultural, mining and forklifts.

SpecialFocus

eavy equipment machinery power has evolved from human or animal to fossil fuels and now electric. The advancements to mechanical power units increased the scale and productivity of equipment. Today, skilled operators can take advantage of advancements in attachment tools that allow equipment to be more flexible and accurate.

Enclosed cabs enhance safety and comfort while maintaining good visibility. The cab is an operator protective structure and is required to meet global or regional safety standards for: rollover protection (ROPS), operator protection (OPS) and falling object protection (FOPS). Industry specific glazing test standards contribute to the safety of the occupant while maintaining the structural integrity of the cab.

UHMW and Nylon in Heavy Equipment Applications

By Will Holdsworth, Mitsubishi Chemical Group

here may be no better example of performance plastics being seen as the engineering materials they are than their presence in construction and heavy equipment. The environment these large machines — mobile cranes, excavators, material handlers, graders and bulldozers, to name a few — operate within are some of the most demanding found in any industry. From the outside, these machines look to be made entirely of metals such as steel and cast iron, but look under the surface and you will find ultra-high molecular weight polyethylene (UHMW-PE), high density polyethylene (HDPE), nylon, acetal and even thermoset laminates hard at work enabling motion, reducing weight and maximizing the performance of the machinery.

History has shown that finding the right material for a given application requires a wide range of base polymers and formulations designed for specific performance within construction and heavy equipment. The most common applications using these materials include wear pads, pivot bearings, sheaves, rollers, outrigger feet and outrigger pads.

SpecialFocus

f the variety of performance plastics available for use in the heavy equipment industry, monomer cast nylon type 6 and type 6/12 materials are a tried-and-true staple. For anything from a pivot bushing in an engine cowling to a cushion pad at the top of a piling, cast nylon 6 and 6/12 has been trusted to perform in a wide variety of applications and environments for more than 60 years. You may ask, what is it about this material that makes it a good fit for heavy equipment and how has it been able to be depended on for so long?

Cast nylon type 6 and 6/12 share some common benefits among many performance plastics materials that are used in heavy equipment. These unique benefits address problems in applications that can arise when using metal materials such as brass, bronze steel and other metals. The obvious ones include their perseverance in the elements. Performance plastics do not rust or corrode. They hold up well to the heat and cold. Also, they are much lighter than steel, metal and alloy materials making equipment more efficient, capable of increased payloads and reducing fuel consumption. Many performance plastics are useful for preventing wear between moving steel components. They also assist in dampening vibration and reducing noise which also improves equipment operation and operator safety. Cast nylon 6 and 6/12 possess these advantages for heavy equipment and many more.

ince the early 1970s, cast nylon 6 has been recognized as a qualifying substitute for metals. Mechanical engineers were initially astonished by the performance of this thermoplastic material’s performance and started using it as a substitute for cast iron, steel and aluminum. Significantly lighter than steel, approximately 1/7th its specific weight and 30 percent lighter than aluminum, cast nylon 6 offers a multitude of advantages and is used in a variety of ways.

Following the advancement of the casting process, cast nylon 6 can be molded into various shapes and wall thicknesses thar are not possible with traditional extrusion or injection molding technology. Through the implementation of various additives, the properties of the cast nylon material can be designed for specific applications. This versatility makes cast nylon 6 an excellent choice for industrial usage.

Originally used as a bearing material, cast nylon is now an industrial favorite for a wide variety of applications. From bushings and wear pads to heavy loaded sheaves for steel ropes, numerous applications are possible.

Convention Coverage

APD – The Performance Plastics Association, the international trade association comprised of companies engaged in the distribution and manufacturing of performance plastics, held its premier annual event September 12-15, 2022 at the JW Marriott Tampa Water Street in Tampa, FL USA. Full convention and one-day delegates participated in educational sessions from renowned keynote speakers as well as industry experts and connected at exciting networking gatherings.

In addition to the numerous learning opportunities, delegates experienced new and creative networking opportunities, from social hours to receptions to a tour of Raymond James Stadium.

The IAPD connecX tradeshow was held on Thursday. It featured booths with meeting areas and the ability to set up appointments prior to the event with an all-new appointment-setting program.

The convention wrapped up with a lively closing party at American Social, featuring a live band that performed something for everyone. Attendees enjoyed fantastic food and drinks, dancing, Thursday Night Football and more!

Save the date: The 67th Annual IAPD Convention will be held October 23-26, 2023 at the Sheraton Sand Diego Hotel and Marina in Sand Diego, CA USA. We look forward to seeing you there!

Thank you

to our

From left: President Deborah Ragsdale presents Past President Craig Saunders with the Paul Davis Award of Merit.

Paul Davis Award of Merit

The prestigious 2022 Paul Davis Award of Merit was presented to Craig Saunders of North American Plastics by 2021 recipient Wayne Gono of Regal Plastic Supply Company, Inc. Saunders served on the IAPD Board of Directors, Executive Committee and two terms as IAPD president from 2019 through 2021. His term as president had just begun a few short months prior to the COVID-19 pandemic. With performance plastics’s role in keeping essential businesses open in early 2020, Saunders was interviewed numerous times by various media outlets. His knowledge of manufacturing and distribution, plus his ability to be calm in a crisis, made him the perfect spokesperson for the industry. In addition, Saunders led the Supply Chain Efficiencies Task Force, which not only developed vital resources for IAPD members coping with Proposition 65 labeling requirements and transportation shortages, it paved the path for IAPD member companies to work together to tackle important industry issues.

The Closing Party

at SPORTS & SOCIAL CLUB

Yamauchi

When asked about his first-year goals at SEKISUI KYDEX, Yamauchi shared “I am looking forward to focusing on our business strategy and product engineering. Over the next year, I will spend time understanding our product, how it’s made and the differentiation factors, ensuring we provide the best service to satisfy customer needs.”

Corporate Profiles

transport critical fluid with confidence

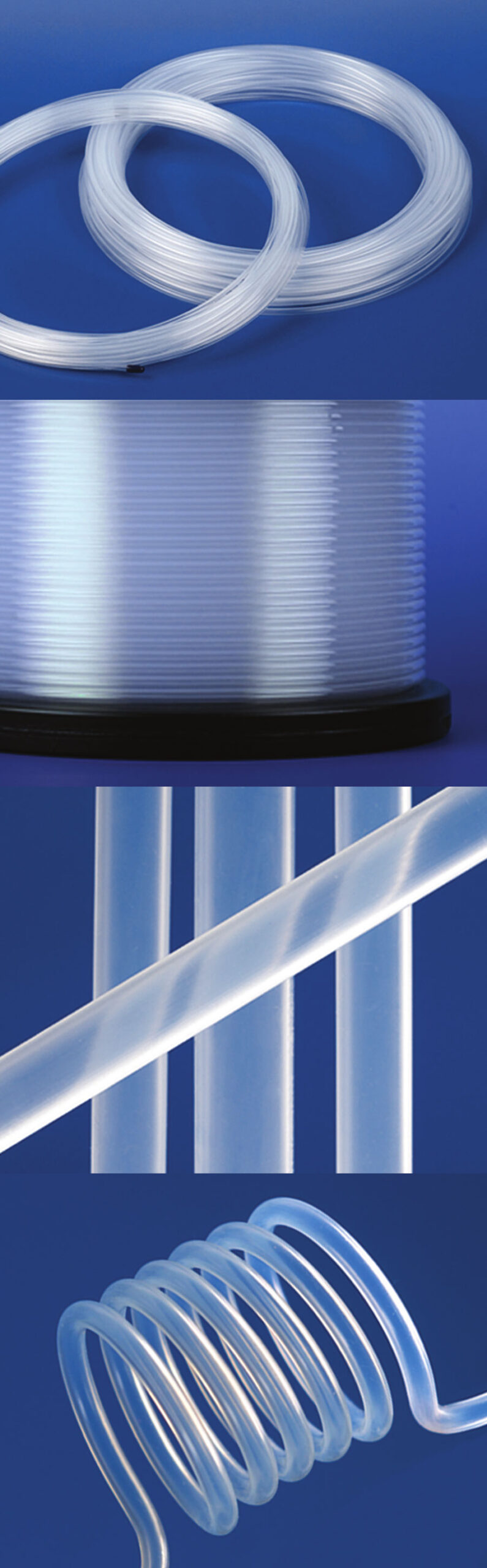

ltaflo, a Pexco Company, is an innovative producer of high performance fluoropolymer and fluoroplastic tubing, pipe and profiles. Since the company’s inception, Altaflo has maintained a consistent focus on the critical requirements of even the most demanding applications.

Their process begins by selecting the highest performance resin grades within each product category. Although there are many resin producers, and various grades offered in each group, Altaflo uses only high molecular weight resin products to ensure optimum performance. These resins provide the highest stress crack resistance, greatest chemical resistance and overall superior performance in their finished products.

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

PTFE

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

Contact Altaflo at 973-300-3344 or sales@altaflo.com.

High Performance Tubing for: Ground Water Testing & Monitoring, Soil and Water Remediation, Air Sampling, Laboratory, Aerospace, Automotive, Environmental, Semiconductor, Laboratory, Food Process and Chemical Process Industries

Overcoming Industry Challenges with Duratron® Polyimide Shapes and Direct-Formed Parts

n the current business climate, it’s understood that OEMs and engineers are under intense pressure to meet material design demands to support increasing loads, with higher speeds, at elevated temperatures. Customers want materials that will adapt to fit their exact needs, but at a lower cost.

Mitsubishi Chemical Group (MCG) has been working on ways to help overcome these challenges and one answer may be Duratron® PI. Polyimides like Duratron PI are high-end engineering polymers that perform at the highest level in extreme environments and can do their job when other high-performance plastics fail.

Created from a resin formulation, Duratron PI is made from monomers to produce fully imidized polyimide parts and does not require post-curing. Because of its chemical structure, it is a non-meltable pseudo thermoplastic polymer, with a well-defined Tg (glass transition temperature) designed for opportunities in state-of-the-art applications. Duratron PI has higher mechanical properties in tensile, flexural, and compressive strengths while providing lower tolerance capabilities and thermal conductivity. Its components can help keep your systems running through improved performance and efficiency and raise part reliability, therefore limiting the Mean Time Between Repair (MTBR).

geared towards excellence

olymer Industries has more than 45 years of experience in performance plastics manufacturing. They are proud the quality standards that formed the foundation of the company are still in place today. As the business expanded to meet the request of its customers, their product portfolio expanded also.

Polymer Industries has one of the largest product offerings from a single manufacturer including: Densetec® high density polyethylene (HDPE), polypropylene (PP), high molecular weight polyethylene (HMW), low-density polyethylene (LDPE) and Polyslick® ultra-high molecular weight (UHMW-PE). Their Mechanical Division produces a variety of Mechetec® high performance materials, acetals and extruded nylon.

the plastics experts

he AGRU success story has been unfolding now for more than seven decades. Founded in 1948 by Alois Gruber Sr., today the company is one of the world‘s most important single-source suppliers for piping systems, semi-finished products, concrete protection liners and lining systems made from engineering plastics.

Seventy years on, AGRU has become a genuine global player. The AGRU Group has plants on three continents and employs more than a thousand staff worldwide. Given that exports currently account for 95 percent of its business, there are AGRU customers all over the globe. Within the industry, AGRU is synonymous with premium quality, customer focus, reliability and professionalism in all areas of plastics engineering. From smartphones to laptops and TV screens, numerous digital devices are now manufactured using AGRU products. Global groups such as SAMSUNG and LG rely on the ultra-pure PURAD piping system made in Bad Hall for their semiconductor production. In the United States, the hidden champion produces large-scale polyethylene pipes with diameters of up to 3.5 m and lengths of up to 600 m. These large pipe strings, weighing up to 1,000 metric tons, are then shipped across the world’s oceans to their deployment locations. One major driver of success in the development of an industrial empire spanning several continents was extensive application engineering expertise, combined with a comprehensive premium plastics engineering portfolio.

over 70 years of experience

endrick has been in operation since 1952. Since their beginning, they have taken pride in providing world-class, high-quality panel saws and CNC routers that make production faster, safer and more precise.

Many people in the plastic industry learned how to cut on a Hendrick manual HPS Rail Saw or the automated Pro-H Saw pictured. The Pro-H revolutionized the plastic industry by marrying a saw with a computer to index cut your material with repeatable surgical accuracy. Their saws have stood the test of time — which is why this add from 1981 is still relevant today.

With the introduction of the Pro-H saw, Hendrick created machinery specifically geared toward the plastics industry. They tailored their machines to have a large depth of cut and high throughput speeds, all the while keeping prices extremely competitive. They offer horizontal panel saws, vertical panel saws, cross-cut saws and CNC routers. Each of these come with the Hendrick commitment that you are getting not only a world-class piece of equipment but also their promise that they are with you for the life of the product. No monthly fees, no subscriptions to manage, just support and parts when you need them the most! Plain and simple.

YOUR GLOBAL PARTNER IN ENGINEERING THERMOPLASTIC MANUFACTURING

t PLASKOLITE, their mission is to produce innovative engineering thermoplastics the right way, through long-lasting customer relationships, hands-on customer service and responsible manufacturing.

PLASKOLITE is a global leader in manufacturing engineering thermoplastics including acrylic (extruded, continuous cast, cell cast), polycarbonate (monolithic, multiwall, laminates), ABS and PETG sheet, lighting profiles and PMMA polymers. Founded in 1950 by Donald Dunn and family, PLASKOLITE has a reputation for providing the highest quality products in the industry. Their innovative thermoplastic sheet solutions are used in a wide variety of applications, including glazing, safety shields, lighting, signs and point-of-purchase displays.

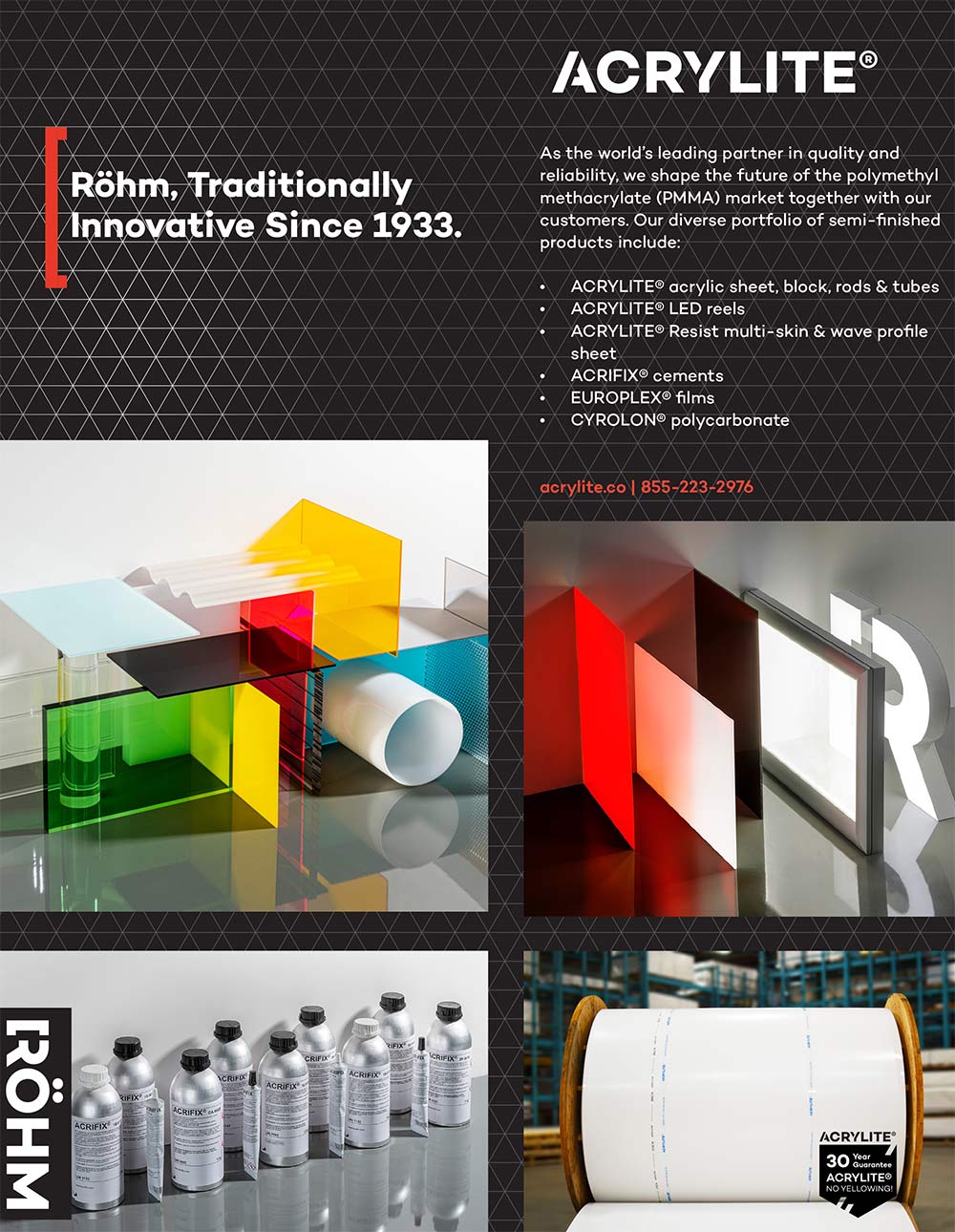

traditionally innovative

öhm is a leading supplier of methacrylate chemicals worldwide. Thanks to their positioning as a global company with 15 production sites on four continents, Röhm is close to their customers and markets. As one of the world’s leading partners in quality and reliability, they are committed to defining the methacrylate markets of tomorrow together with their customers.

With their diverse portfolio of semi-finished ACRYLITE® products, they are one of the world’s leading manufacturers of polymethyl methacrylate (PMMA). Further brands such as CYROLON, EUROPLEX® and ACRIFIX® offer specialist solutions for signage, medical technology, transportation and other industries. A strong partner for industry and trade, the business unit develops innovative products for sustainable applications.

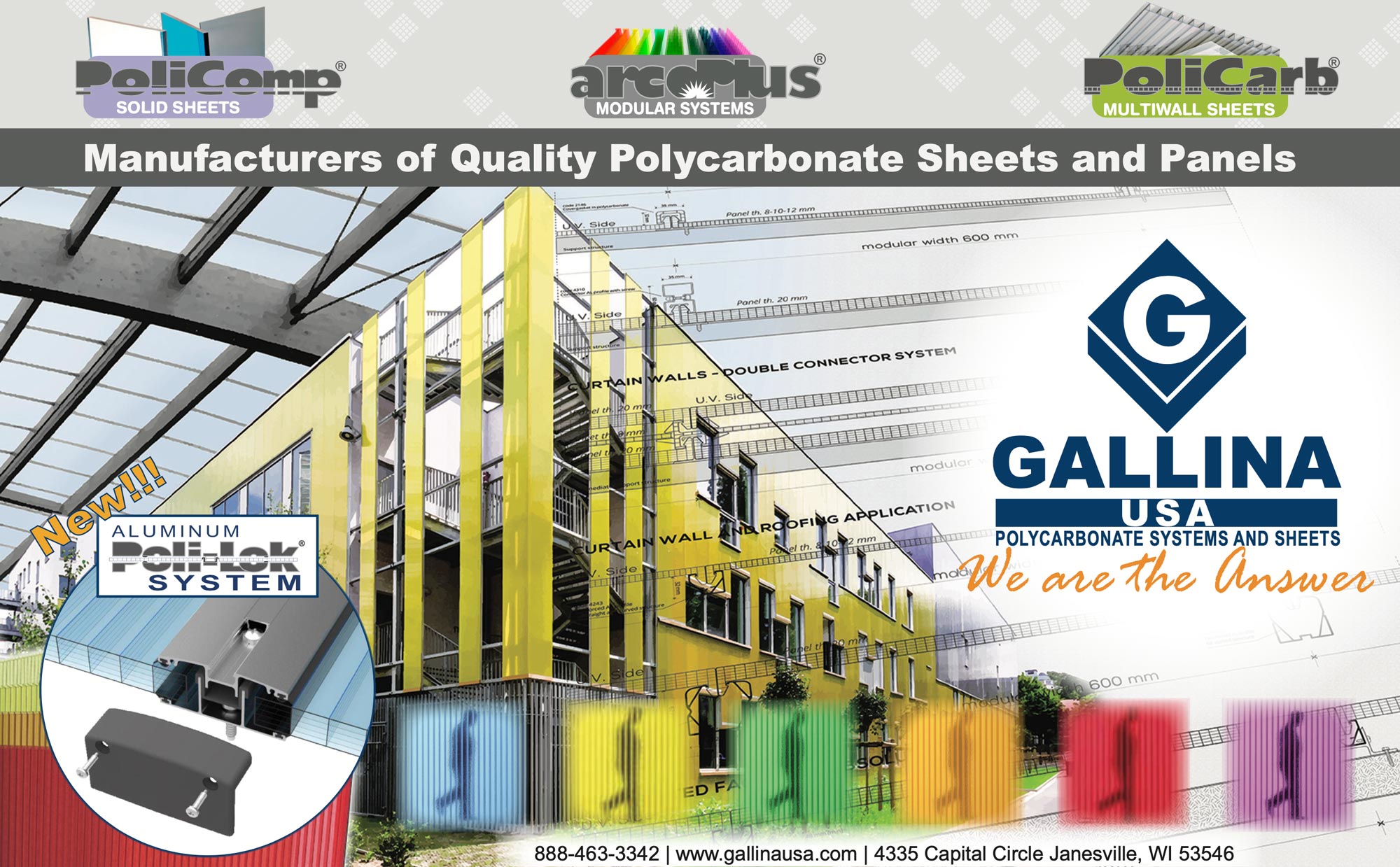

MANUFACTURERS OF QUALITY POLYCARBONATE SHEETS AND PANELS

ott.Gallina SRL was founded in 1960 by Pier Aulo Gallina in La Loggia, Italy specializing in plastic trim production for the automotive industry. Over the subsequent years, Gallina has expanded its product lines and developed polycarbonate sheet and system solutions for the architectural and industrial market sectors. Today, the Gallina companies are renowned producers and suppliers in Europe, the Middle East and the Americas, with production facilities and manufacturing partnerships in Italy, Greece, Turkey, the United States, France, Germany and India with key sales partner- ships throughout Europe and the United States.

Gallina USA, LLC was established in Janesville, WI, USA in 2002 and currently operates a 150,000-square-foot manufacturing and warehousing facility serving the multiwall and solid sheet polycarbonate needs for the distribution, architectural, industrial, horticultural and do-it-yourself (DIY) sectors.

COMMITTED TO QUALITY AND CONTINUOUS IMPROVEMENTS

ince their inception over 50 years ago, Hudson Extrusions, Inc. has been dedicated to a singular goal: “Total Customer Satisfaction.” They strive to exceed their customers’ expectations through outstanding customer service, quick turnaround times and producing extruded plastic tubing and profiles of exceptional quality.

Having been family owned and operated since 1956, they value the personal service that has become scarce in today’s technologically advanced environment. Their knowledgeable sales staff has a combined 40+ years of experience in the plastics industry and are ready to help with any questions or inquiries you may have.

OUR INNOVATION. YOUR IMAGINATION.®

ing Plastic Corporation is a leading manufacturer of quality polymer sheets, slabs and massive shapes — including several products pioneered by the company. Its polymers are made in the United States and sold worldwide through a network of top plastics distributors to customers who fabricate products for the marine industry (King StarBoard® brand), signage, food service, healthcare, architectural, industrial and other markets. King Plastic manufactures more than 20 products including:

- King StarBoard® — The original marine-grade polymer sheet

- King StarBoard® AS — The anti-skid marine-grade polymer sheet

- King StarBoard® XL — The lightweight marine-grade cellular sheet

POLYCARBONATE & PVC POWERHOUSE

023 marks Palram’s 60th anniversary as a global leader in polycarbonate and PVC innovations within the thermoplastic industry. With time-tested resources, proprietary technologies and a rich history of expertise, Palram has become a trusted partner to markets spanning industrial; construction and architecture; safety and security; sign and display; transportation; and outdoor living.

From Palram’s hands-on team and product customization to timely shipping, and sales support, providing world-class service is a priority. In addition, Palram is committed to purposeful innovation, drawing inspiration from emerging market trends and customer requirements to create solutions that are tailored to a wide variety of applications.

Experience the benefits of a nimble, single source supplier of high-quality polycarbonate and PVC.

a global leader in plastics innovation

he Roechling Group, made up of Industrial, Medical and Automotive divisions, employs more than 11,000 people worldwide at 91 locations in 25 countries. Backed by a global network, Roechling Industrial North America is one of the world’s leading manufacturers of high-quality semi-finished thermoplastics, engineering products and composites. Featuring what they believe to be the most comprehensive product line within the United States, Canada and Mexico, Roechling is committed to developing efficient, innovative and sustainable solutions for their customers.

Through continuous investments and improvements in new manufacturing technologies, Roechling products are used and specified by engineers and cater to a wide range of industries.

one-stop shop for CUSTOM plastic sheet extrusion

owmark is excited to announce the expansion of its custom extruded sheet products webpage, www.rowmarkcustom.com. Custom products featured include Rowmark’s LD light diffusing product, impact modified acrylic, ABS sheet and thermoplastic elastomer (TPE) materials.

Mt. Vernon, Indiana, USA

chemistry that matters™

ABIC’s Functional Forms business offers high-quality, engineered thermoplastic sheet and film products across various industries, including building and construction, consumer electronics, automotive, specialty glazing, and air- and rail interiors.

The sustainable design movement aims to reduce the negative impact of residential and commercial buildings on the environment. SABIC’s Functional Forms growing portfolio of LEXAN™ polycarbonate (PC) multiwall sheet products contributes to this movement. It strengthens sustainable building designs by increasing energy conservation, improving working/living environments and promoting recycling. LEXAN sheet solutions can help architects, builders and contractors tap into the “green” building market, a multi-billion-dollar sector and a bright spot in the current construction industry slump. SABIC’s Functional Forms offers its customers a broad portfolio of LEXAN multiwall sheet solutions for roofing, cladding and glazing.

Archbald, Pennsylvania; Newcomerstown, Ohio; Findlay, Ohio USA

THREE MANUFACTURING SITES IN NORTH AMERICA OFFER A DIVERSE RANGE OF PRODUCTS AND SERVICES TO DISTRIBUTORS

IMONA AMERICA GROUP consists of three independent manufacturing and sales facilities: SIMONA AMERICA Industries, SIMONA Boltaron and SIMONA PMC.

Primary materials produced by SIMONA AMERICA Industries include PE, PP, PVC, CPVC, PVDF, ECTFE and PFA. Featured products include:

- BOATBOARD® marine grade HDPE

- Polygrain® woodgrain HDPE

St. Louis, Missouri, USA

improving the shape of tomorrow by bringing innovation to life at 16 u.s. manufacturing locations

very day, in every part of the world, people benefit from the products Spartech makes. They expertly manufacture engineering thermoplastic solutions for the most demanding markets — Transportation, Aerospace, Building and Construction, Healthcare and Medical, Industrial, Packaging, Signage — for products like yours that make our world safer, easier and a better place to live.

Their Innovation Center creates material efficiency by providing the right products for the right applications and greener materials and processes, their specialized solutions for engineered materials deliver high-quality products that are solutions for a better world.

- Six types of engineered materials

- 10 different manufacturing processes

Burr Ridge, Illinois, USA

the plastic welding experts

egener Welding, LLC is proud to introduce the newest sheet butt welding machine to their range of high-quality welding equipment. The MWD manual welding device is now available!

For smaller scale fabrication requiring sheet butt welding of PP, PE, PVDF, PVC and CPVC, the MWD butt welding machine is a perfect balance between versatility, high quality and economic value. The MWD is offered in working widths of 1 m (41″), 1.5 m (61″) and 2 m (80″) versions and has intuitive operating controls. Pneumatic table pressure eliminates the need for hand wheels or cranks while ensuring steady, evenly applied pressure during the welding process.