Traditional pipe clamps hold piping in a fixed location. If plastic pipes are held in place too tightly without allowance for thermal expansion, mechanical stress is transferred to the pipe. Stress of this kind on plastic pipes is the leading cause of premature piping leaks and failures. When plastic piping leaks, it is usually near clamping locations.

Stress Less pipe supports are designed to eliminate stress transfer to plastic pipe during thermal expansion. Consisting of a polypropylene insert within a trivalent chrome-coated metal hoop, each Stress Less support leaves room for movement between the inner plastic insert and the pipe. The smooth inner surface of the insert allows the piping to slide freely in the axial direction with minimal stress and wear during each thermal expansion cycle. Meanwhile, the outer metal bracket never meets the pipe, no matter how tightly it is bolted down at installation.

Stress Less also protects pipes from damage during seismic activity. The gap between pipe and support is engineered to prevent severe impact on the pipe in the event of an earthquake. In addition, the steel metal hoop can support the weight of piping even during strong seismic events, meeting ANSI/MSS SP-58 requirements for pipe hangers and supports. GF Piping Systems created Stress Less to protect pipes in a wide variety of conditions, giving users peace of mind.

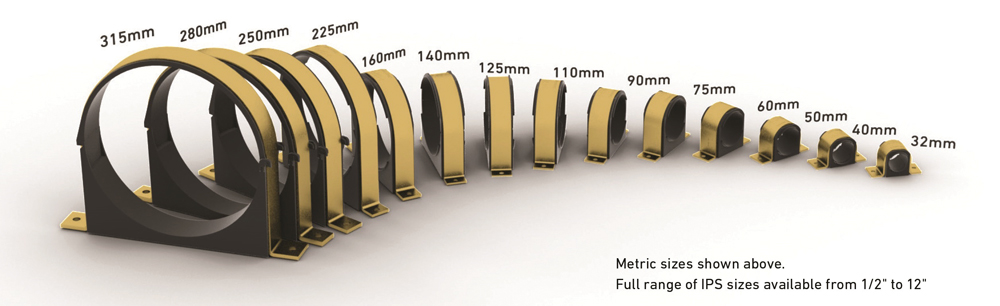

Stress Less guides are available in metric sizes ranging from 20 mm to 315 mm, including the newly available 125 mm, 140 mm, 250 mm, 280 mm and 315 mm sizes. Stress Less guides are also offered in IPS sizes ranging from ½” to 12″, including the new 5″, 10″ and 12″ units.

Stress Less is engineered to protect and extend the life of thermoplastic piping systems. The supports can be used with many materials and systems including PVDF, PP, PVC, CPVC, HDPE, ABS, ECTFE, double-contained piping and pre-insulated plastic piping systems. The hoops are coated with a trivalent gold chromium-coated steel which protects the brackets from rusting, corrosion and wear, and the plastic inserts are made from a UV resistant polypropylene plastic for added durability. These materials make Stress Less suitable for a variety of indoor and outdoor installation settings, from highly corrosive environments to high purity facilities. www.gfps.com/us.

Celtec materials are available in 10 standard colors, three finishes and thicknesses ranging from 1-38 mm in a variety of sizes. Vycom can provide custom colors and run-to-size manufacturing of the entire Celtec line, which can help streamline the production process of high-volume, digitally printed graphics. Print service providers, exhibit houses and fabrication studios that use large quantities of materials can maximize yield and reduce waste by bypassing pre- or post-cutting rigid PVC and go straight into print production once materials are received. Colors tailored to meet clients’ identity or brand needs can also be manufactured, within available thicknesses or finishes. www.vycomplastics.com.

By the end of this year, Arkema plans to offer several SCS-certified grades that meet critical performance standards while also offering a traceable supply chain. SCS is a global third-party environmental and sustainability certification body (www.scsglobalservices.com/about/company). Detailed lifecycle analysis data packages will be available upon request. The grades are produced using only renewable energy.

“More and more, our customers are interested in innovative recycled options in order to drive improved sustainability and circularity in the supply chain,” according to Erwoan Pezron, Arkema’s senior vice president for High Performance Polymers. “The ability to design certified recycled grades with high performance and lower carbon footprint is an exciting step in the sustainability journey of our customers and Arkema. Extending the life of these polymers, sometimes in applications quite unrelated to their original use is gratifying. The growth potential is significant.” www.arkema.com.