UHMW and Nylon in Heavy Equipment Applications

By Will Holdsworth, Mitsubishi Chemical Group

here may be no better example of performance plastics being seen as the engineering materials they are than their presence in construction and heavy equipment. The environment these large machines — mobile cranes, excavators, material handlers, graders and bulldozers, to name a few — operate within are some of the most demanding found in any industry. From the outside, these machines look to be made entirely of metals such as steel and cast iron, but look under the surface and you will find ultra-high molecular weight polyethylene (UHMW-PE), high density polyethylene (HDPE), nylon, acetal and even thermoset laminates hard at work enabling motion, reducing weight and maximizing the performance of the machinery.

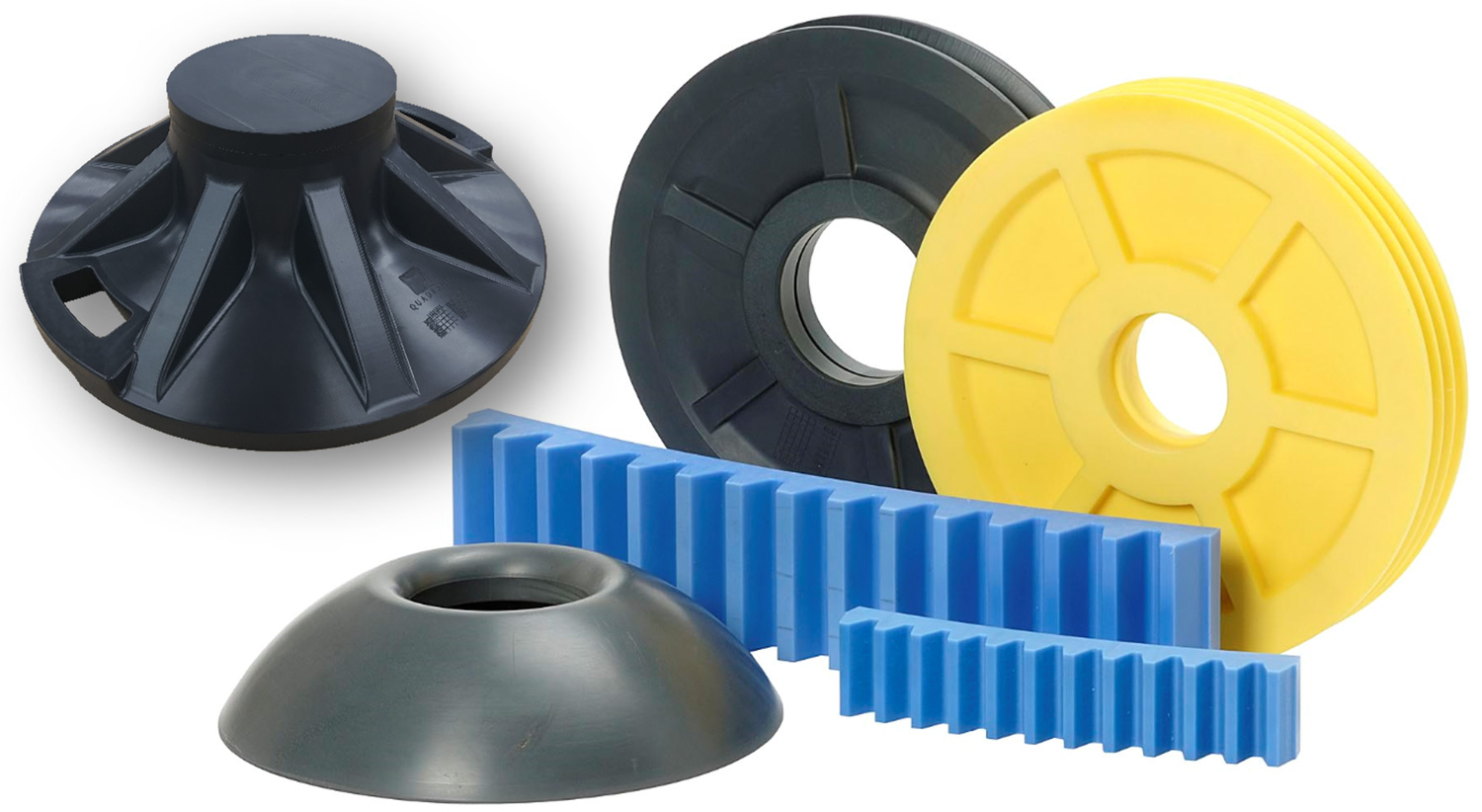

History has shown that finding the right material for a given application requires a wide range of base polymers and formulations designed for specific performance within construction and heavy equipment. The most common applications using these materials include wear pads, pivot bearings, sheaves, rollers, outrigger feet and outrigger pads.

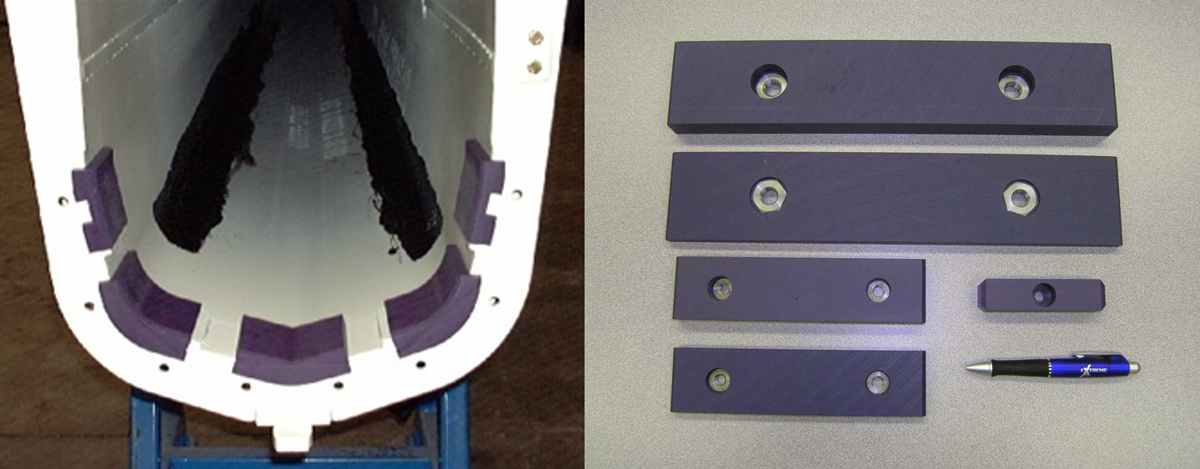

Contoured (left) and traditional wear pads (right) machined from Nylatron 703XL will significantly reduce or eliminate boom chatter.

Cast nylon 6 parts shown using MCG Nylatron (spun-cast sheaves, outrigger feet, gear segments and pivot point liners).

Nylon and UHMW wear pads or slide bearings enable telescoping booms to extend and retract with minimal external lubrication. These parts were once made from bronze and other soft metal alloys that required constant greasing. In a typical wear pad, recessed steel inserts allow the pads to be rigidly fastened to the steel or aluminum boom. A typical example of wear pads is shown above. The size and shape of the boom, type of paint used and access determines the size and shape of the wear pad as well as how it gets attached. The maximum stress determines the base material. Small booms with lower resultant stress often glide on UHMW-PE based wear pads. When the maximum contact stress is less than 750 psi and extension/retraction speed slow a UHMW pad is often considered. Enhanced glass bead filled and self-lubricating grades generally do best. Cast nylon 6 based wear pads enable design engineers to design around peak loads approaching 6000 psi. Once again, self-lubricating grades do best, especially as stress and speed increase.

Contoured (left) and traditional wear pads (right) machined from Nylatron 703XL will significantly reduce or eliminate boom chatter.

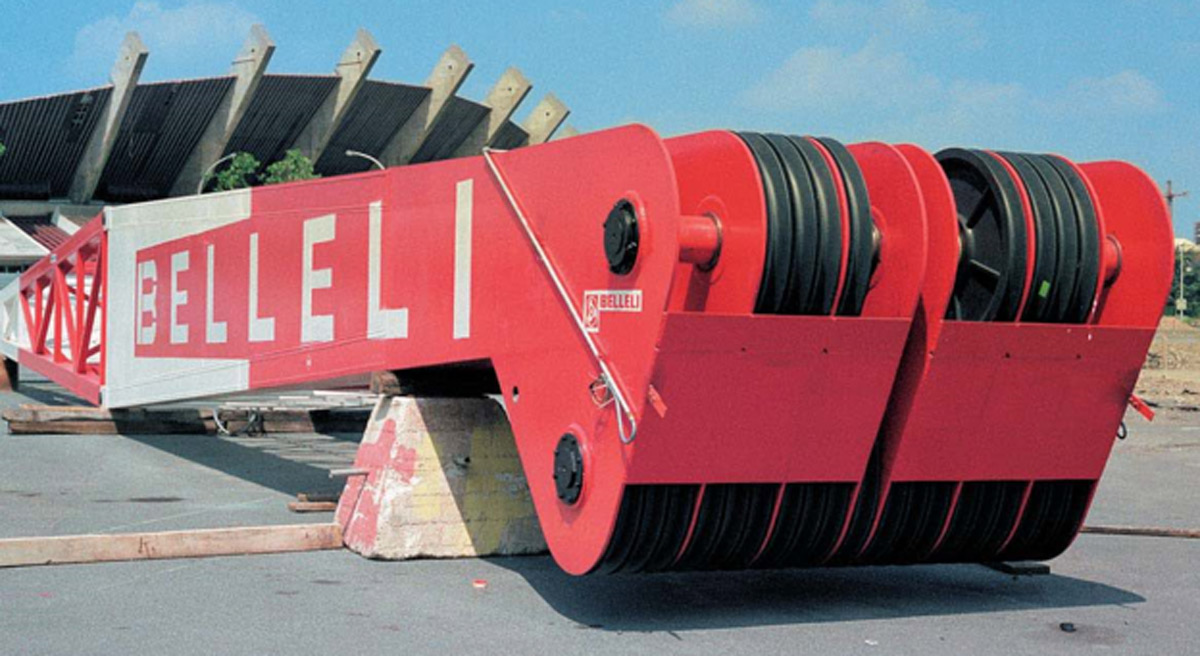

Nylon sheaves have been used in mobile cranes for more than 50 years. Nylon’s lighter weight (1/7th that of steel), high strength and overall durability means increased lifting capacity, lower over-the-road weight and longer wire rope life with no sacrifice in performance. One may ask how it is possible that nylon sheaves can lift as much load as steel sheaves. The wire rope is what dictates the stress limit. These limits and lower contact stress due to nylon’s resiliency means a sheave’s groove stress is almost always within nylon’s operating range, provided a sheave groove to wire rope ratio of 18:1 to 24:1 is used. These nylon sheaves almost always include roller bearings, especially when part of a reaving system. The bearings are selected based on expected service conditions, especially maximum line pull and rope speed making these parts engineered assemblies. Engineers at the OEM, understanding the expected service conditions and nylon’s maximum stress limits, design parts so that the stress at the bearing-nylon interface remain below 3500 psi. Bearing retention is also part of what design engineers must consider. Internal and/or external snap rings may be specified to prevent bearings from moving axially due to side loading.

Sheaves larger than 14″ diameter are commonly spun cast using dedicated tooling allowing for cast in webs, ribs and even lightening holes to be incorporated into the design. These design features provide significant weight and cost reductions, especially when production volumes are high enough to warrant spinning in custom molds. Sheaves smaller than 14″ diameter are typically machined from rod or tube but can even be made from plate via CNC routers.

Nylon and UHMW are also used to stabilize units that have extended booms during operation. Castable nylon outrigger feet are replacing welded steel and cast aluminum outrigger feet as they are less prone to theft while offering weight savings. These feet are often positioned over outrigger pads or cribbing plates made from UHMW-PE, a much more durable option than plywood.

One of the most surprising applications where you can find engineering plastics is in the tracks of tracked vehicles such as excavators, trenchers and even cranes operating in swampy marshes. When soil conditions require low ground pressure, equipment designers can use tracks made from cast nylon or even UHMW which can be made in longer lengths to provide additional surface area, thereby reducing the pressure under the tracks. Ground pressures of 1-2 psi are possible using these engineering materials when undercarriage designs allow for longer lighter-weight tracks.

Track plates made from Nylatron PA6 achieve low ground pressure by increasing surface area and lowering weight.

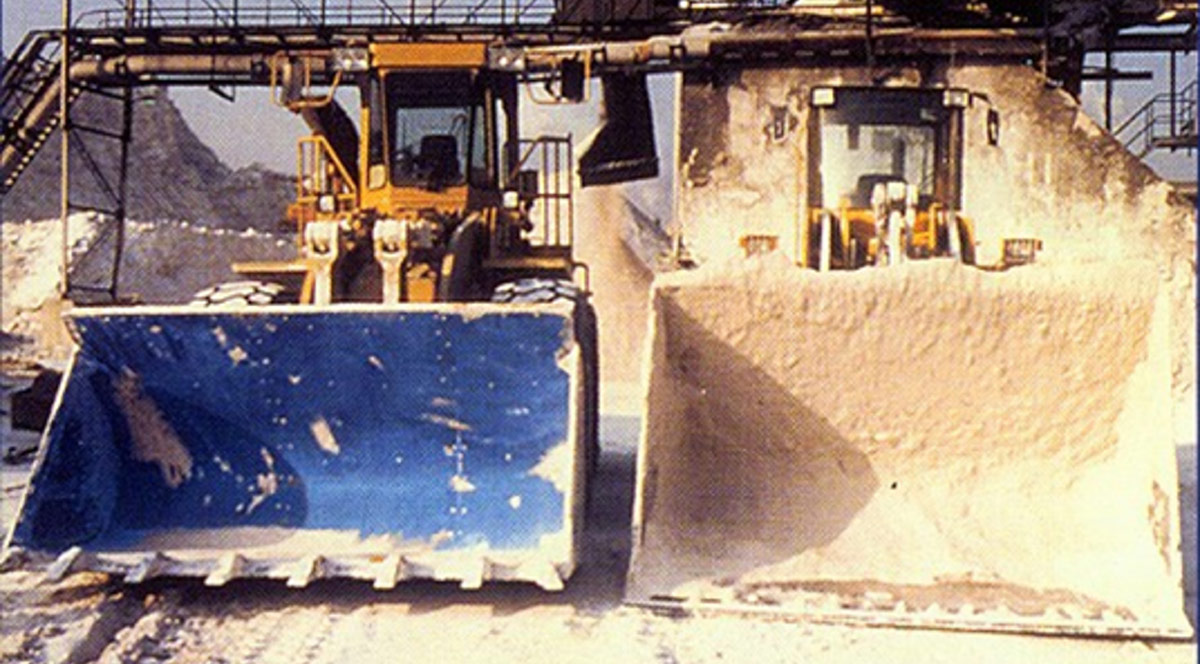

In addition to the above-mentioned components, UHMW linings systems improve the transportation of aggregate in many off-road construction vehicles, especially those used to transport gravel, clay and asphalt. Low coefficient of friction, abrasion resistant UHMW liners in a truck bed or loader bucket protect metal surfaces from damage and degradation, while accelerating unloading and eliminating aggregate carry-back. These systems can be replaced at end of service life at a much lower cost than the steel surfaces they protect. The material and design are carefully matched to the operating conditions and overall design of the vehicles. Lining systems should always be engineered systems rather than sheet simply fastened to metal structures.

When durability matters, nylon and UHMW excel. Both material families offer the balance of strength, low friction, good wear and abrasion resistance that heavy equipment requires. The equipment is large and many of the parts are, too. Custom nylon castings help many of these shapes and parts be economically produced while large UHMW sheet and rod help fabricators efficiently mill and turn parts.

Will Holdsworth is a sales engineer for Mitsubishi Chemical Group. For more information, contact Mitsubishi Chemical Group at 2120 Fairmont Avenue, Reading, PA 19612-4235 USA, (800) 366-0310 or (610) 320-6600, fax (800) 366-0301, william.holdsworth@mcam.com or www.mcam.com.