The transparent barriers made of acrylic or polycarbonate sheets are placed between support railings. These clear sheets are available in various thickness, length and colors. These barriers are solely for isolation and meet the strictest criteria of the European standards (EN Norms) regarding devices for the reduction of road traffic noise. Policam Sound block sheet that’s 15 mm thick and weighing in at around 18 kg/m2 reduces the noise level by a noticeable 30 dB (certified according to EN 14388). www.siriusplastics.com.

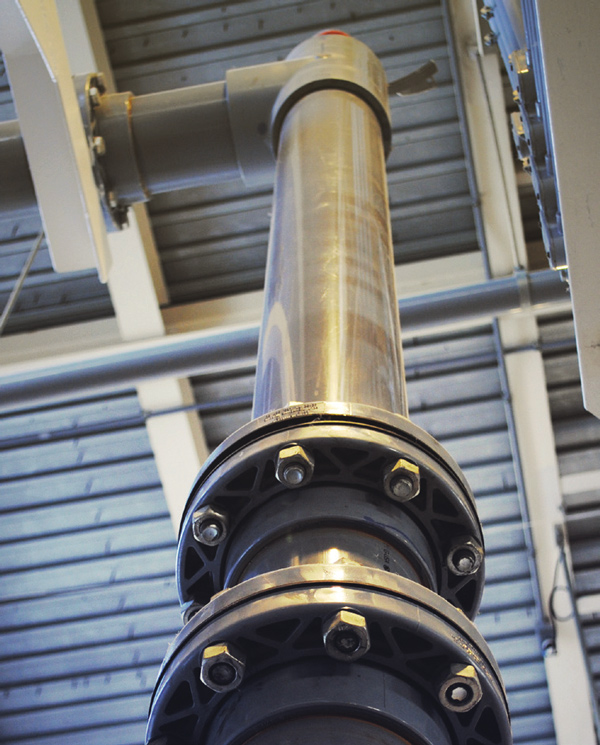

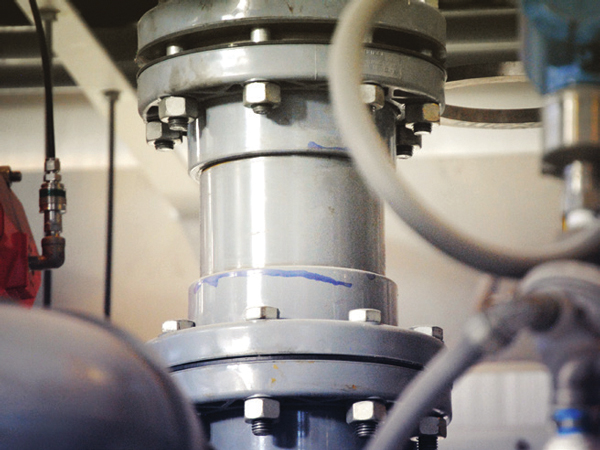

Lubrizol’s TempRite CPVC resin process includes acidic and corrosive materials that generally require exotic piping materials able to withstand contact with the unstripped, acidic resin slurry. Metals such as titanium, however, are expensive and still tend to show the same deterioration as other piping materials.

“TempRite is a 24-hour, seven-day-a-week operation that has often been pushed to capacity,” said Chris Costin, TempRite resin area specialist. “The piping system used must be highly reliable as it transports the manufactured material a distance from reaction to drying. One failure can result in a costly process shutdown that impacts our ability to serve customers.”

Lubrizol selected Corzan CPVC piping for the TempRite resin production area in 1987. The previous system was comprised of titanium and various lined piping components. Corzan CPVC offered purchase price advantages over titanium and other metal piping without sacrificing performance. Schedule 80 Corzan CPVC piping cost approximately 93 percent less than Grade 2 schedule 80 titanium piping and about 46 percent less than schedule 40 stainless steel piping. The Corzan CPVC piping also offered savings throughout the system’s life in the form of increased operational efficiency, less maintenance and minimal downtime.

The plant installed Corzan CPVC piping for applications in other areas, such as the Vycar drumming line, the TempRite compounding city water system and waste pump-out system. Corzan sheet material was used in an inclined plate clarifier application and the B-Line dryer scrubber system.

“Space is usually the greatest challenge during redesigned piping system installations,” said Joe Newton, TempRite manufacturing manager. “But, once the design was complete, Corzan CPVC was simple to install and required minimal time.”

Corzan CPVC piping used in the Louisville plant ranges from ¼” to 8″ in diameter, with 10″ and 12″ piping custom fabricated for the plant’s reactor relief and wastewater neutralization systems.

“The pipes and fittings are well suited to the plant’s process conditions, which are harsh in terms of corrosion, abrasiveness and temperature,” said Lynn Huff, TempRite compound area leader. “Corzan CPVC piping has proven a durable and cost-effective alternative to expensive exotic metals.”

The piping system’s projected life varies and depends on the specific system installed and the application conditions. As an example, Corzan CPVC piping was installed in the facility’s B-Line production unit in 1992 and most of the original piping is still in use today.

Lubrizol will use Corzan CPVC piping for any future applications where the product ensures cost-saving performance and longevity. For more information about Corzan CPVC and the Louisville piping application, visit www.corzan.com.

That’s why entrepreneur Kevin Kennett developed the JIB Box (www.jibbox.com), a sturdy, lockable package receptacle that can be secured to porches for door-front deliveries. “With the state of the economy, there’s been a real increase in the theft of packages,” said Kennett, founder and president of JIB Lock Box LLC. “Additionally, home delivered packages need to be protected from inclement weather.”

After three years of research and development, Kennett launched the JIB Box in May 2020 with two models: one constructed with black 6 mm SINTRA® PVC panels by 3A Composites USA, Inc. and the other with birch panels. “We needed to find the right material and lock,” said Kennett. “It had to be weather-resistant, hold up well and be sturdy enough to keep packages safe. … We consulted a box manufacturer and they recommended SINTRA for its weather-resistance and durability.”

SINTRA is a high-performance moderately expanded PVC board engineered for graphic display projects that require quality material. According to the manufacturer, SINTRA is easily fabricated and known for its printability, quality, consistency, durability and performance. SINTRA is available with a premium bright-white surface for digital and screen printing. In addition to the brightest white and black, SINTRA is available in a broad range of colors in gauges ranging from 1 mm up to 12.7 mm and in standard sheet sizes ranging from 48″ x 96″ up to 2 meters x 120″.

Working with contract designers, the JIB Box was designed with an aluminum frame and premium panels and features an interior storage compartment measuring 19″ wide x 13″ deep x 13″ tall — a size designed to accommodate 90 percent of all packages shipped, according to Kennett, who said hardware is provided to secure the JIB Box to a porch.

The JIB Box features a mechanical digital lock that does not require batteries or keys and is unlocked by owners with a four-digit code. Delivery personnel simply follow instructional stickers adhered to the exterior and interior panels of the JIB Box, place packages inside and turn a knob to activate the lock.

SINTRA has held up well in these JIB Box purchases, according to Kennett, who said the SINTRA model “has received zero complaints for lack of sturdiness, dents or scratches.”

Kennett contracts C & C Manufacturing Inc. in Sterling Heights, MI, USA to manufacture the JIB Box models. Black SINTRA is supplied to C & C Manufacturing by the Warren, MI, USA branch of Laird Plastics and by the Madison Heights, MI, USA branch of Polymershapes LLC.

“The fact that SINTRA can be routed with a CNC machine really helps with manufacturing and production,” said Kennett. “We also are able to easily adhere graphics to the SINTRA panels.”

Kennett uses the JIB Box at his residence and lake house, owning one with black SINTRA panels and the other with birch panels. “The concept is working fantastically,” said Kennett. “Our biggest concern was in getting delivery personnel to use it. They’ve used it from the get-go. They just follow the instructions on the stickers and don’t need a code. JIB Box provides ease of use for the delivery person.” www.3acompositesusa.com.

Kynar Aquatec is a solvent-free PVDF resin for aqueous paint formulations which, when applied as a topcoat, provide lasting protection for the whiteness and reflectivity of paints for up to 20 years. It resists aging and mold and is based on Arkema’s expertise in Kynar® 500 PVDF resins, which have been used for decades to protect metallic coatings on buildings from corrosion and dirt.

Painting roofs white is a common practice to remedy the absorption of solar radiation for areas with strong sunlight. But conventional paints rarely hold up beyond five years. They lose their “reflectivity” with the appearance of dirt and micro-fungi and the intensity of UV rays damage them, making them porous. From an environmental point of view, repeatedly recoating a damaged surface negates the benefits of reflectivity.

The transparent protective coating based on Kynar Aquatec resin helps keep the whiteness of the coating intact for more than 20 years with very little maintenance. This topcoat acts like a varnish: rainwater washes away any dirt that would stick to a traditional white paint. Roof instrumentation repainted in white and protected by a topcoat based on Kynar Aquatec have shown that overall energy costs linked to the air conditioning of the building can be reduced by 15 to 30 percent.

Cool Roof reflective coatings are applied manually or by spraying on waterproofing membranes or on various roofing materials (tar, cement, metal), previously cleaned. In addition to energy savings, white roofs also improve the living conditions of city dwellers by combating the effects of urban heat islands. These coatings are able to return up to 95 percent of solar radiation back into the atmosphere.

The importance of passive air conditioning through reflective roofs was first seen in the 2000s in the United States. The Intergovernmental Panel for Climate Change (IPCC) in Europe considers it “one of the fastest and cheapest solutions for adapting to climate change.” The IPCC has calculated that painting the roofs white would save 1 Gt / year in greenhouse gas emissions, or the equivalent of 250 million vehicles worldwide. Candidates for cool roofing include hypermarkets, storage warehouses and factories. Cool Roof estimates that in France alone, flat commercial roofs and terraces represent around 500 million square meters (that’s more than 5.3 million square feet). www.arkema.com.