of

Machining and Fabrication Processes

With Hot Air Tools

for the Performance Plastics Professional

For Cutting Extruded Acrylic

Can Be the Right Fit

For the Job

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

IAPD President

s I write this, we are coming up on the one-year anniversary of the global COVID-19 crisis. In some ways it seems like it’s been much longer than 12 months since we heard the shocking news as major event after major event canceled, from the NCAA basketball tournaments to the Olympics and more.

On a more somber note, as time progresses, it is getting increasingly more difficult to find people who have not been impacted by COVID-19. My heartfelt condolences go out to all who have lost family and friends to the virus.

IAPD CEO

f you’re looking for a new year’s resolution that will benefit you and the performance plastics industry, I suggest you consider finding a volunteer opportunity within IAPD. IAPD’s offerings to its members are only possible through a collaboration between paid staff and a large network of member volunteers. We need your expertise!

What is in it for you? Let’s take a look at some of the many benefits of volunteerism.

Kynar Flex PVDF fluoropolymers impart high chemical resistance, resistance to swelling, UV resistance, high heat stability, high contact angle and good release properties. Rubbers can impart a range of other favorable properties such as impact strength, flexibility, strain recovery, electrical resistance, lightweight, softness and compressibility. The final combination of properties can be tailored by the selection of the base fluoropolymer and the rubber, or combinations of rubbers, which will determine overall cost and performance.

here’s a good chance that you’ve seen the well-publicized images of plastics in the ocean and related horrific photos of ocean life impacted by plastics. You may have to justify your livelihood in the performance plastics industry to friends and relatives who have absorbed this anti-plastics messaging for years, if not decades (or, depending on their generation, most of their lives).

Being in the performance plastics industry, we know that the durable plastics we manufacture and distribute are different from the consumer-grade plastics that usually end up in oceans. We can talk about the many ways in which performance plastics are a means to an end for otherwise unattainable environmental goals. For example, thanks to the use of performance plastics instead of metals in automobiles and aircraft, there is a need for less fuel because the cars or airplanes are lighter and more fuel-efficient.

Although there are many innovative projects that try to remove plastics from the ocean, they haven’t been able to do so in a significant way. There has to be another approach, a way to prevent these materials from getting into the oceans in the first place.

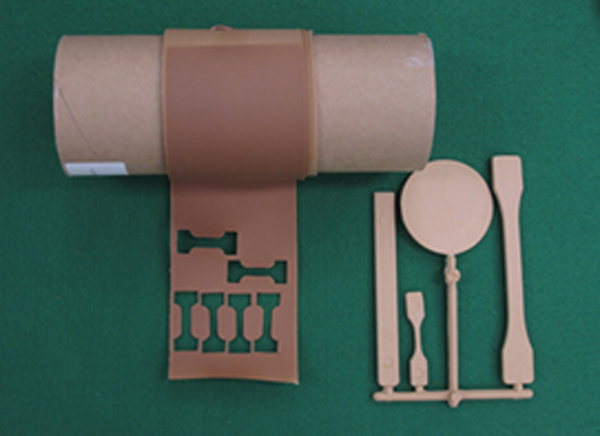

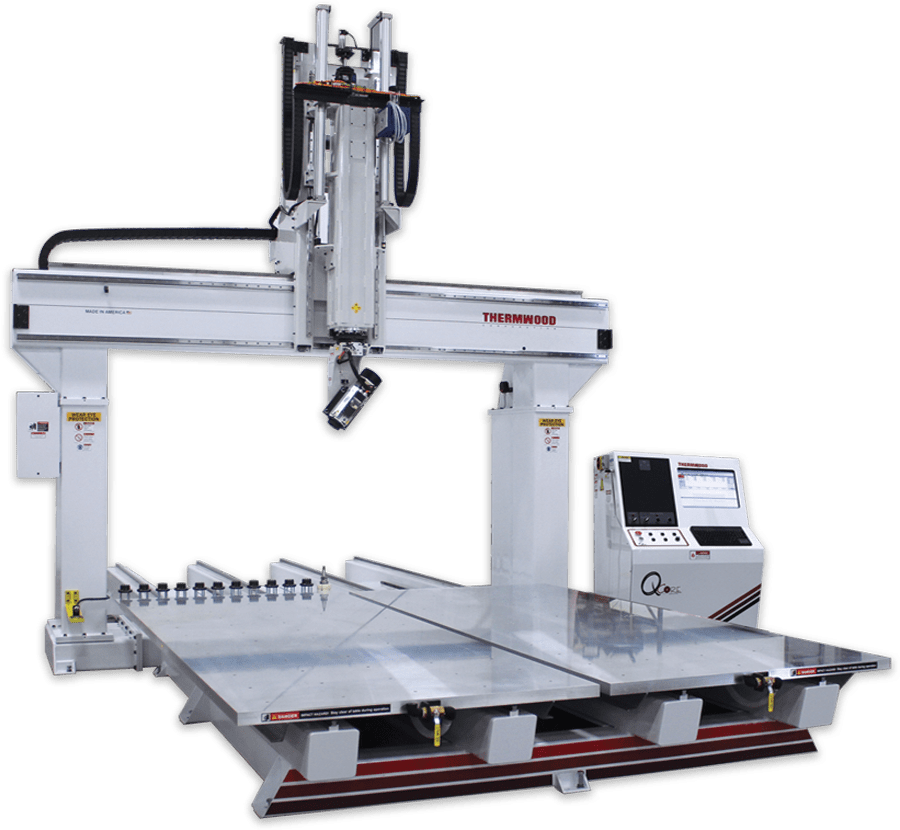

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

800-533-6901

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

800-533-6901

omputer Numerical Controlled (CNC) machinery is everywhere. CNC fabrication of plastic shapes is becoming more common in the performance plastics industry. We are seeing more routers everywhere, and soon most distributors will have at least one router somewhere in their organization. Many distributors already have several routers in different locations.

But what about other fabrication equipment? Besides cutting a 2-dimensional shape out of a sheet of acrylic, what are some machine shops or part manufacturers doing with performance plastics? What different machinery are they using to turn that rod, blank or plate of polymer into a finished part?

Most machine shops simply mill or turn parts. Most of the machines are CNC, but there are still “manual” mills and lathes in use. Manual machines usually have some type of computer control, however, and the measurements are still precise. Let’s take a closer look at the machinery.

oday, there exists a desire — from either a creative or a business perspective — to manufacture products with rigid thermoplastic, using a process commonly referred to as plastic fabrication. This term describes a variety of procedures and processes. This article focuses on describing the process of the joining/welding of rigid thermoplastics using hot air tools, specifically hot air portable extrusion welders. There is another popular fabrication process using hot air hand tools that lends itself to certain situations and applications, but that’s a subject for future consideration.

Gears, machine parts, sprockets, star wheels, wear strips and more.

Gears, machine parts, sprockets, star wheels, wear strips and more.

utt fusion of thermoplastic sheet, also known as heated element butt welding, has become a standard practice for many plastic fabricators as a result of the unmatched high quality of the welded joints. While sheet materials such as polypropylene (PP), high-density polyethylene (HDPE), polyvinylidene fluoride (PVDF) and polyvinyl chloride (PVC) are commonly found in fabricated structures, a variety of other materials are emerging or becoming more popular in applications that benefit from sheet butt fusion.

When using a butt welding machine, sheet material is positioned against a setting bar that also serves to aid in alignment. After the sheet is set into position onto each side, it is clamped in place and the setting bar is replaced by an anti-stick coated heating element. The machine tables press the sheets against the heating element under controlled pressures for the melting/heating cycles. Upon completion of the two-stage melting/heating cycle, the machine tables open, the heating element moves out of its position and the tables come together again, pressing the melted sheet together under a pressure ramp to the full welding pressure. When this high pressure welding/cooling cycle completes, the clamps release the material and the welded sheet can be removed.

The following graph explains the general sheet butt welding sequence (the butt welding pressure ramp):

he growth in demand for extruded acrylic has been exponential over the last decade. Stronger yet lighter than glass, extruded acrylic is the go-to choice for fabricators who want a durable-yet-cost-effective material for a variety of applications.

If you are just getting started with extruded acrylic, you may find it challenging to cut, even with a great router from a trusted manufacturer. These five easy tips can make the entire cutting process easier for you.

hen people hear the word custom, they usually think expensive. Their mental calculator starts adding up charges for design time, prototypes, tooling, molds, etc. Yes, a custom project can cost more than purchasing something off the shelf, but that’s only looking at part of the equation. In some cases, having a tank custom fabricated may even save you money.

What does it mean to have a plastic tank custom fabricated? As the user of the tank, you dictate its size and shape. More importantly, you make the decisions about how many and the placement of the fittings and connections required for your tank. By being able to design the tank to the exact specifications of your space, layout and needs, not only will you have a tank that fits perfectly in the available space, you will save money by not having to retrofit the surrounding area to fit your tank.

he correct tooling makes all the difference in the world for production performance. High-quality, precision tooling is designed to withstand demanding tasks and helps increase production and efficiency. The correct tooling ensures quality and extends the life of your equipment.

A number of factors should be considered when determining which tooling is right or best for you and your application — and it’s not something that should be taken lightly.

The Equipment Leasing and Finance Association (ELFA) which represents the nearly US$1 trillion equipment finance sector, announced its Top 10 Equipment Acquisition Trends for 2021. Given U.S. businesses, nonprofits and government agencies are expected to spend more than US$1.8 trillion in capital goods or fixed business investment (including software) this year, financing a majority of those assets, these trends impact a significant portion of the U.S. economy.

ELFA President and CEO Ralph Petta said, “Not surprisingly, the effects of the COVID pandemic loom large in the list of trends this year. Despite upheaval throughout the economy, equipment acquisition continues to drive supply chains across all U.S. manufacturing and service sectors. Nearly eight in 10 of U.S. businesses use equipment leasing and financing to acquire the productive assets they need to operate and grow. We are pleased to again provide the Top 10 Equipment Acquisition Trends at a time when businesses need to understand the market environment more than ever to make their strategic equipment acquisition plans.”

e were all hoping that when the calendar changed from December 31, 2020 to January 1, 2021, we would be able to leave the worst of last year behind us. Unfortunately, 2021 appears to be more of the same, at least in Washington, D.C.

With the inauguration of President Joe Biden, the same party controls Congress and the White House. However, there is a 50-50 split in the Senate, which has not happened since 2001. Legislating in the COVID era has been challenging, but with control of both legislative bodies we anticipate President Biden will take aggressive action over the next two years. The next election will be the midterms in 2022; historically, the President’s party does poorly in midterm elections.

Courtright

According to Interstate Plastics, “Mark’s influence and significance on Interstate Plastics cannot be understated. He has dedicated his years with Interstate Plastics in building a competitive, integrity focused and forward-thinking organization. His impact will be felt for years to come and will be maintained thanks to his determined effort in developing a solid company culture for those that are not so lucky as to retire just yet.”

The next few months of transition will see several organizational changes at Interstate Plastics. Larry Chavez, currently the company’s CFO, will assume the title of president. Mike McKenna, currently sales development manager, will assume the role of general manager with branch management oversite. Many of the additional duties and activities currently under Courtright’s purview will be delegated to Chavez and McKenna as is appropriate as well as to John Schwenck in his role as director of corporate operations.

Kietzke

Kietzke joined the company in 1984 and has held a variety of positions in sales, marketing and management. His significant contributions include the company’s entry into the polymides market, opening its Texas and Asia locations and establishing effective international marketing tactics. He was instrumental in the development of its CRM software and launched the company’s first eCommerce website, both of which he still oversees and continues to adapt in line with the evolving market. In addition to his chief marketing officer role, Kietzke will also continue in his capacity as executive director of Asia, as well as his advisory role as a corporate board member and executive shareholder.

“Chris is committed to the future growth of the company and will continue to expand and enhance our marketing and eCommerce efforts in his new role,” said Dave Kietzke, Professional Plastics CEO and chairman of the board.

processing — no matter what techniques are involved, Stiles has the CNC technology to get it done. Their machining solutions can be custom-configured to your specific needs. From productivity and high precision, to energy and material savings, Stiles provides proven CNC options for plastics processing. For more information, contact info@stilesmachinery.com or visit www.stilesmachinery.com.

processing — no matter what techniques are involved, Stiles has the CNC technology to get it done. Their machining solutions can be custom-configured to your specific needs. From productivity and high precision, to energy and material savings, Stiles provides proven CNC options for plastics processing. For more information, contact info@stilesmachinery.com or visit www.stilesmachinery.com.

Artek, Inc. • (800) 762-6808 • www.artek-inc.com

Ensinger • (800) 243-3221 • www.ensinger-inc.com

Hudson Extrusions, Inc. • (800) 837-6015 • www.hudsonextrusions.com

King Plastic Corporation • (941) 493-5502 • www.kingplastic.com

Leister Technologies LLC • (855) 534-7837 • www.leister.com

Norplex-Micarta • (563) 864-7321 • www.norplex-micarta.com

Plazit-Polygal Group • (800) 537-0095 • www.polygal-northamerica.com

Polymer Industries • (877) 765-9637 • www.polymerindustries.com

Roehm America LLC • (800) 631-5384 • www.acrylite.co

Rowmark LLC • (877) 769-6275 • www.rowmark.com

Schelling America, Inc. • (919) 544-0430 • www.imaschelling.us

Thermwood Corporation • (800) 533-6901 • www.thermwood.com

Vortex Tool Co. • (800) 355-7708 • www.vortextool.com

Wegener Welding, LLC • (630) 789-0990 • www.wegenerwelding.com

Tim Brown • Röchling Engineering Plastics • Dallas, North Carolina, USA

Brad Caplan, Executive Committee • Polymershapes • Charlotte, North Carolina, USA

Stephen Garmon • Primex Plastics Corporation • Richmond, Indiana, USA

Wayne Gono, Immediate Past President • Regal Plastic Supply Company • Dallas, Texas, USA

Gerry Helbig • Curbell Plastics, Inc. • Orchard Park, New York, USA

Jeff Mikitka • Mitsubishi Chemical Advanced Materials • Reading, Pennsylvania, USA

Deborah Ragsdale, Vice President • Polymer Industries • Henager, Alabama, USA

Jim Richards, Executive Committee • PLASKOLITE • Columbus, Ohio, USA

Craig Saunders, President • North American Plastics • Irving, Texas, USA

Drew Schwartz • Colorado Plastic Products • Louisville, Colorado, USA

Cinthia Snell • North American Plastics • Irving, Texas, USA

Jeff Toth • National Plastics & Seals, Inc. • Schaumburg, Illinois, USA

Scott Van Winter • Vycom • Scranton, Pennsylvania, USA

Josh Wehrli, Executive Committee • Harrington Industrial Plastics • Monument, Colorado, USA

6734 West 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE

savery@iapd.org

Editor-In-Chief

Liz Novak, CAE

lnovak@iapd.org

Advertising Sales

Sean Moore

smoore@iapd.org

Design and Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Vice Chair Courtney Kincaid • Polymershapes • Charlotte, North Carolina, USA

Board Liaison Jeff Mikitka • Mitsubishi Chemical Advanced Materials • Reading, Pennsylvania, USA

Sherrie Bloom • Curbell Plastics, Inc. • Orchard Park, New York, USA

Chris Corona • CartierWilson LLC • Newcomerstown, Ohio, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Zack Loeprich • Total Plastics, Int’l • Kalamazoo, Michigan, USA

Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

John Schwenck • Interstate Plastics • Sacramento, California, USA

George Southard, CPMR • GS Sales • Westfield, Indiana, USA

Tania Summers • Laird Plastics • Dallas, Texas, USA

Ed Townsend • Braskem America, Inc. • Philadelphia, Pennsylvania, USA

6734 West 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE

savery@iapd.org

Editor-In-Chief

Liz Novak, CAE

lnovak@iapd.org

Advertising Sales

Sean Moore

smoore@iapd.org

Design and Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Vice Chair Courtney Kincaid • Polymershapes • Charlotte, North Carolina, USA

Board Liaison Jeff Mikitka • Mitsubishi Chemical Advanced Materials • Reading, Pennsylvania, USA

Sherrie Bloom • Curbell Plastics, Inc. • Orchard Park, New York, USA

Chris Corona • CartierWilson LLC • Newcomerstown, Ohio, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Zack Loeprich • Total Plastics, Int’l • Kalamazoo, Michigan, USA

Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

John Schwenck • Interstate Plastics • Sacramento, California, USA

George Southard, CPMR • GS Sales • Westfield, Indiana, USA

Tania Summers • Laird Plastics • Dallas, Texas, USA

Ed Townsend • Braskem America, Inc. • Philadelphia, Pennsylvania, USA