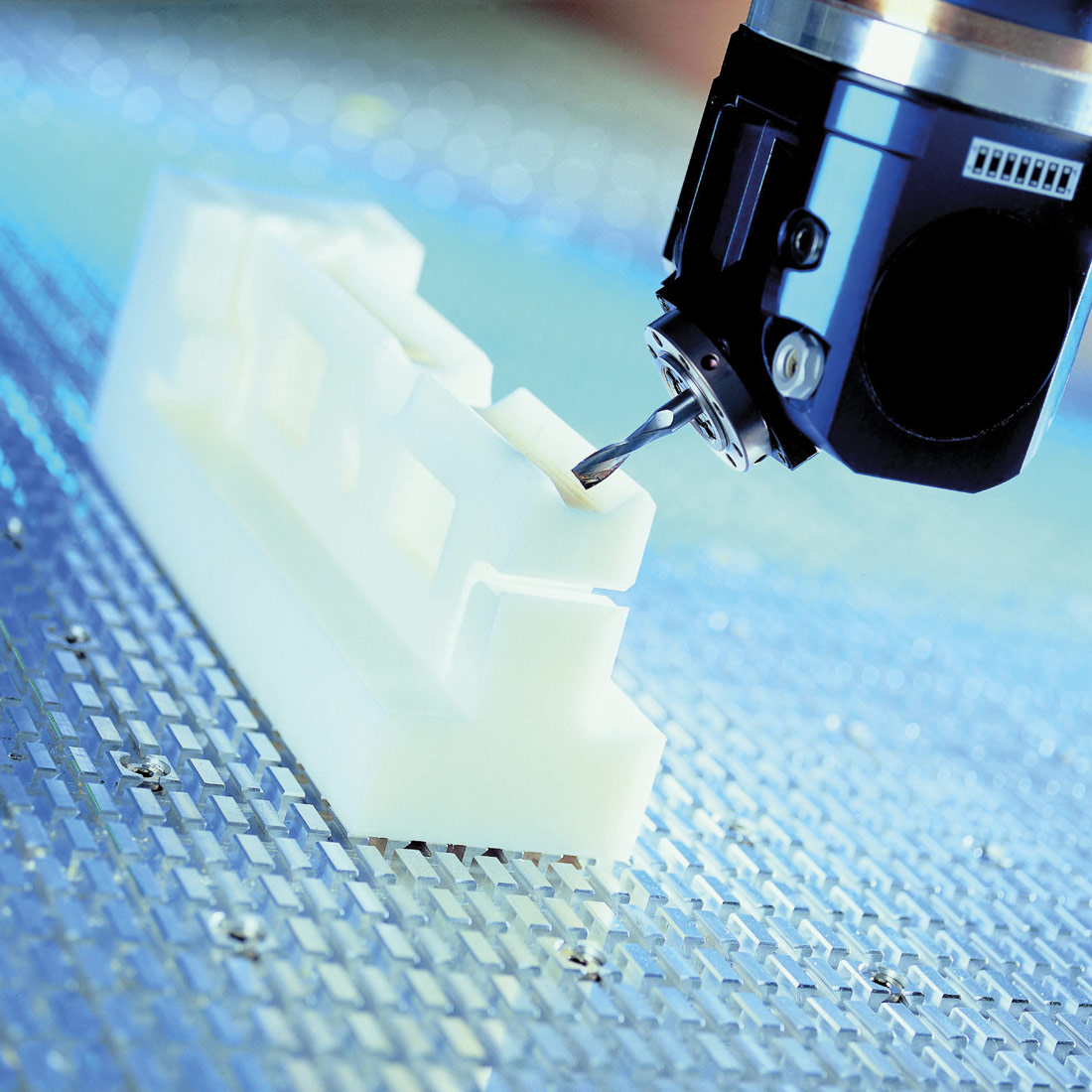

he correct tooling makes all the difference in the world for production performance. High-quality, precision tooling is designed to withstand demanding tasks and helps increase production and efficiency. The correct tooling ensures quality and extends the life of your equipment.

A number of factors should be considered when determining which tooling is right or best for you and your application — and it’s not something that should be taken lightly.

Another conversation that will need to take place is whether you’ll need carbide-tooling or diamond-tipped tooling. While diamond tooling will cost more, its performance life cycle is much longer.

Diamond tooling offers longevity, which translates into cost savings from not having to purchase or service the tools as often. Diamond tooling will also reduce production slowdowns due to infrequent servicing of the machine. In comparison, if you choose less expensive tooling, you’ll have to purchase or service your tooling more often, which will likely lead to more costly downtime.