utt fusion of thermoplastic sheet, also known as heated element butt welding, has become a standard practice for many plastic fabricators as a result of the unmatched high quality of the welded joints. While sheet materials such as polypropylene (PP), high-density polyethylene (HDPE), polyvinylidene fluoride (PVDF) and polyvinyl chloride (PVC) are commonly found in fabricated structures, a variety of other materials are emerging or becoming more popular in applications that benefit from sheet butt fusion.

When using a butt welding machine, sheet material is positioned against a setting bar that also serves to aid in alignment. After the sheet is set into position onto each side, it is clamped in place and the setting bar is replaced by an anti-stick coated heating element. The machine tables press the sheets against the heating element under controlled pressures for the melting/heating cycles. Upon completion of the two-stage melting/heating cycle, the machine tables open, the heating element moves out of its position and the tables come together again, pressing the melted sheet together under a pressure ramp to the full welding pressure. When this high pressure welding/cooling cycle completes, the clamps release the material and the welded sheet can be removed.

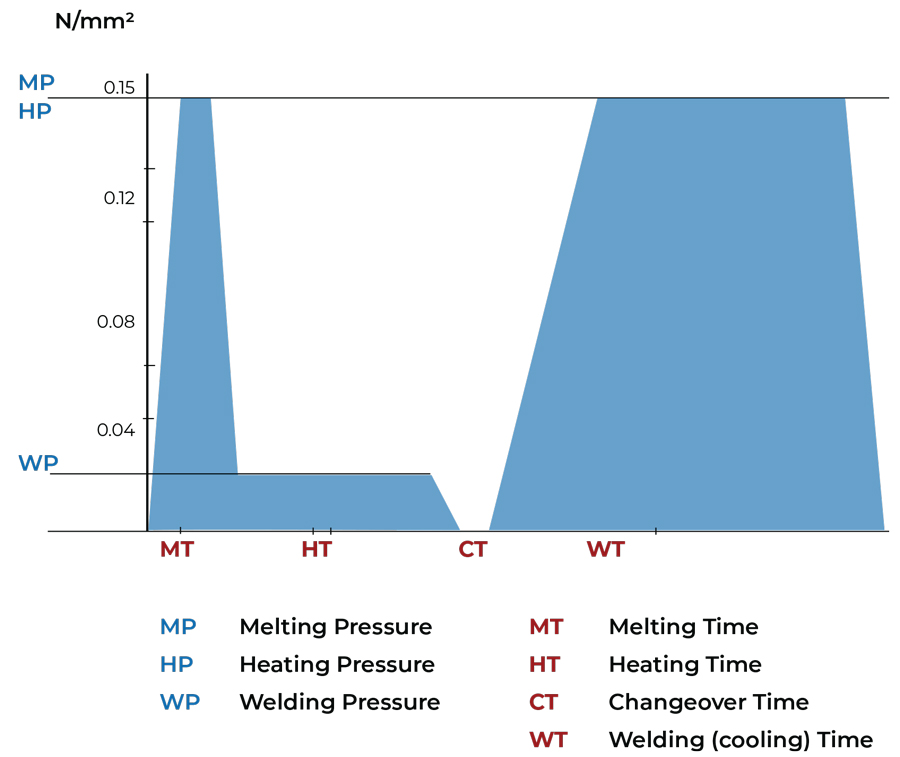

The following graph explains the general sheet butt welding sequence (the butt welding pressure ramp):

- The high pressure melting cycle assures that a bead is formed across the length of the material against the heating element to guarantee even material contact.

- The low pressure heating cycle allows the sheet to slowly absorb the heat being transferred into the welding zone.

- The changeover time — that is, the time it takes for the element to be removed and the tables to bring the two sheets into contact with each other — must be minimal to avoid excessive cooling or oxidation of the surfaces being welded.

- Pressure build-up time is critical to prevent too much material from being pressed out of the weld zone. If full pressure is applied immediately after changeover, most or all of the molten material would be pressed out of the weld zone resulting in a cold weld of material that did not absorb the necessary heat to be in a thermoplastic state.

- The welding time allows the molecular chains to intertwine and cool down while under high pressure, forming a true molecular bond.

Most sheet butt welding machines are microprocessor equipped to facilitate setting of the welding parameters and assure full repeatability. Provided the parameters are set correctly, heated element butt welding is the strongest weld in the area of fabrication. While operators need to load the machine, align the material properly and set parameters according to the material, the automated application of pressure for precise lengths of time helps ensure evenness across the weld.

- Machine frame, construction and guide/travel elements

- Material clamping fixtures and their impact on machine base

- Machine table travel parallelism and table top alignment

- Heating element positioning, temperature accuracy and surface condition

- Machine controls

Many of the machines available today are equipped with full CNC controls and can be optimized to include force or table travel monitoring, data logging and recording of all welds for quality assurance and tracking purposes. Machine precision in construction and functionality are prerequisites for the quality of the welds as well as durability and longevity of the machine itself.

- Welding surfaces: All welding surfaces must be clean, especially when welding sheet because sheet butt fusion machines do not incorporate surface preparation, which is performed with the facing/planning operation in pipe welding.

- Condition of heating element: Element surfaces should have clean anti-stick coating, free of residue and easily release hot melt. Elements should be cleaned and recoated when necessary. Residue on the element can contaminate the weld zone and lead to weld failure.

- Verification of welding parameters: When changing parameters, welds should be tested and validated. It is also good practice to validate welds with newly received sheet lots.

The strength of a process-controlled butt weld allows for making larger size sheets or reclamation of smaller pieces into workable sizes. In addition, today’s sheet butt welding technology allows for welding of 90º corners, proving versatile in fabrication of tanks and closed channels. Vacuum clamps hold the vertical sheet in place, sometimes accompanied by mechanical clamps, while the horizontal piece is aligned against the setting bar. Welding temperatures, pressures and cycle times are generally the same as horizontal sheet-to-sheet welding.