or more than half a century, plastic welding has proven to be a valuable technology employed in a wide array of industries. The continuous ingenuity of entrepreneurs around the globe have expanded the need for plastic welding technologies far beyond common uses such as tank manufacturing, ventilation and piping systems. A lesser known — but highly successful application benefitting from plastic welding — is the manufacturing of semiconductors.

If you’ve seen the news lately, you will know that the demand for semiconductors has soared in recent months. With inventories at all-time lows, many suppliers are determined to increase production capabilities in North America to prevent future shortages. That could mean an increase in the need for performance plastics used in manufacturing processes. Being a multibillion-dollar industry, governments and large corporations worldwide dedicate sizable financial resources to add and improve manufacturing capabilities.

Semiconductors are used to regulate the flow of electrons in circuit boards, which are key to producing the microchips used in almost every electronic device. While conventional uses including cellular phones, computers and televisions are well known, a wide range of other products use semiconductors as well: Temperature sensors in HVAC units and kitchen cooking electronics, LED light bulbs, appliances, banking ATMs, train and rail systems, automobiles, internet services and many more products and industries rely on semiconductors to function. Even clean energy products such as solar panels and wind turbines rely on semiconductors.

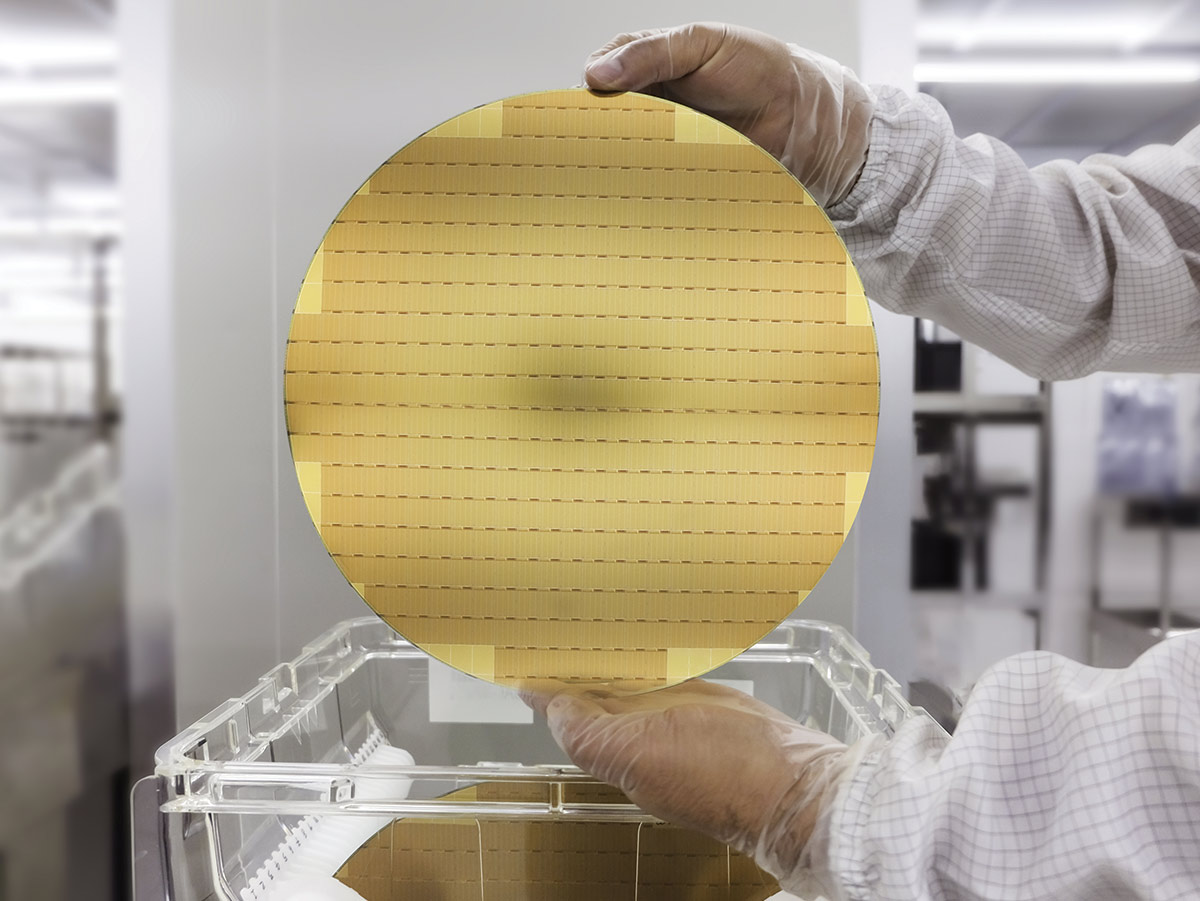

To produce semiconductors, a silicon wafer must first be produced. This process includes melting raw silicon crystals at temperatures greater than 2000°F/1093°C to ensure the highest purity. Impurities such as boron and/or phosphorus are added to the pre-purified, molten silicon to change its electrical properties. The molten mixture is then manipulated using temperature and rotation to create a cylindrical crystal (or boule).

Using a high precision saw, the boule is sliced into thin wafers. The wafers are then put through various machines for processing such as spin coating, polishing, photolithography, etching or an array of other processes based on the product or customer requirements.

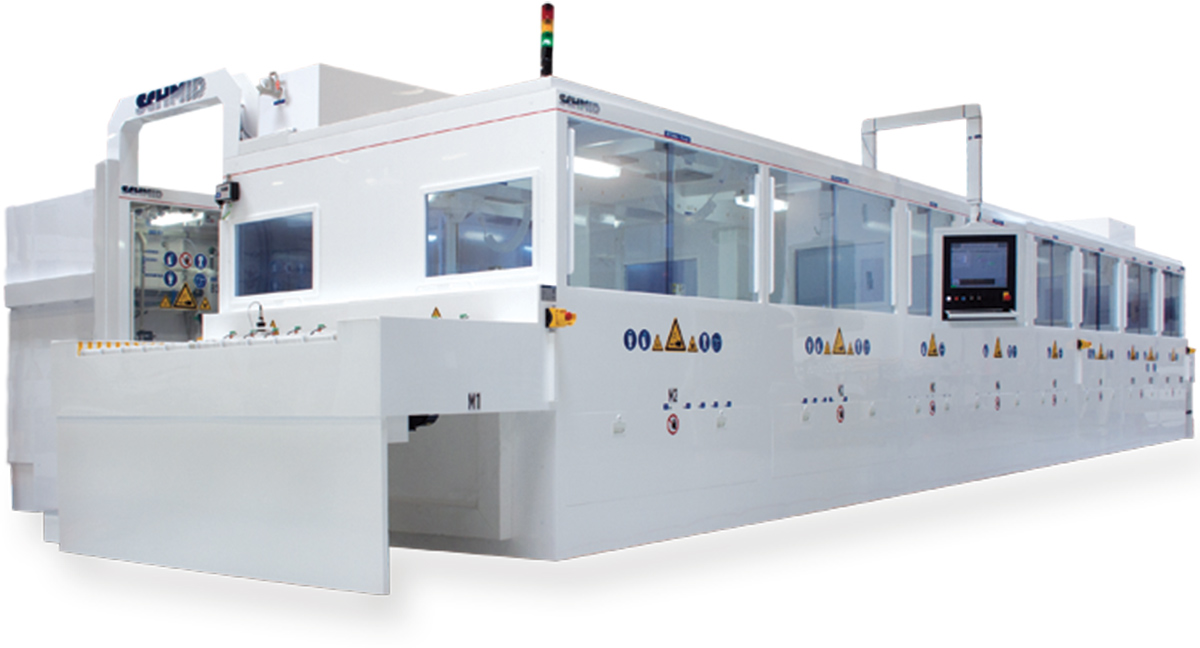

Performance plastics play a crucial role in almost every step of production. Due to the requirement for highest purity, the processing lines are often enclosed using a range of amorphous and semicrystalline materials including polypropylene (PP), polyvinyl chloride (PVC), polyvinylidene fluoride (PVDF), perfluoroalkoxy (PFA), polyetheretherketone (PEEK), polytetrafluoroethylene (PTFE) and ethylene-chlorotrifluorethylene (ECTFE). Cleaning the raw materials often requires the use of welded plastic rinse tanks, cradles and dipping baskets. Electroless and immersion plating tanks and piping systems also benefit from welded thermoplastics. Semiconductor manufacturing lines and facilities sometimes require high-quality ventilation and filtration systems, often made from welded thermoplastic materials.

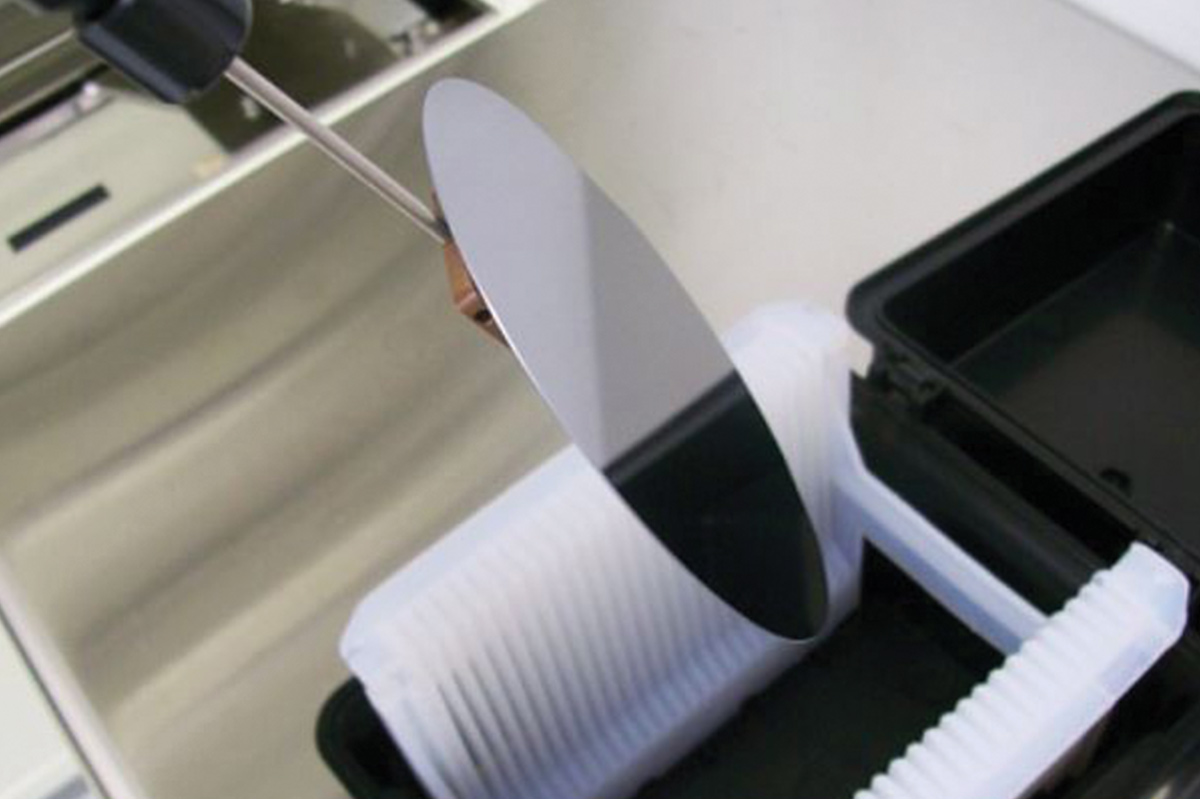

Processing semiconductor wafers uses plastic carriers, or cassettes, for transfer, storage and thermal processing. These wafer cassettes are made from several types of plastics such as PP, PFA, PEEK and PVDF. The welding processes used for production of wafer carriers include hot gas welding, butt welding, ultrasonic welding and infrared (IR) welding. While specialty machines for welding wafer carriers can be custom made, most manufacturers use conventional welding methods to produce cassettes.

Welding fluoropolymers requires appropriate personal protective equipment (PPE) to ensure the operators’ safety. Polymer fume fever (aka Teflon flu) can be harmful to the operator and can include symptoms such as headache, fever, nausea and chills. In extreme cases, permanent lung damage, known as acute lung injury, from welding certain fluoropolymers is possible. It is strongly recommended to use appropriate PPE, including breathing ventilators and eye protection, and to perform the welding in a well-ventilated area.

The general public’s perception of plastics has, in many cases, been shaped by negative media coverage of plastic trash. Plastics are often criticized or blamed for their role in climate and atmospheric changes based on limited interactions with single-use, consumer-grade plastics. The story that isn’t being told is one that those of us in the performance plastics industry know well: All the expansive benefits from performance plastics that are part of everyday life. From electronics to automobiles, infrastructure and clean energy production, performance plastics and plastic welding technologies continue to improve quality of life for billions of people worldwide.