of

Cover photo courtesy of WEGENER Welding LLC.

PLASTICS FABRICATION

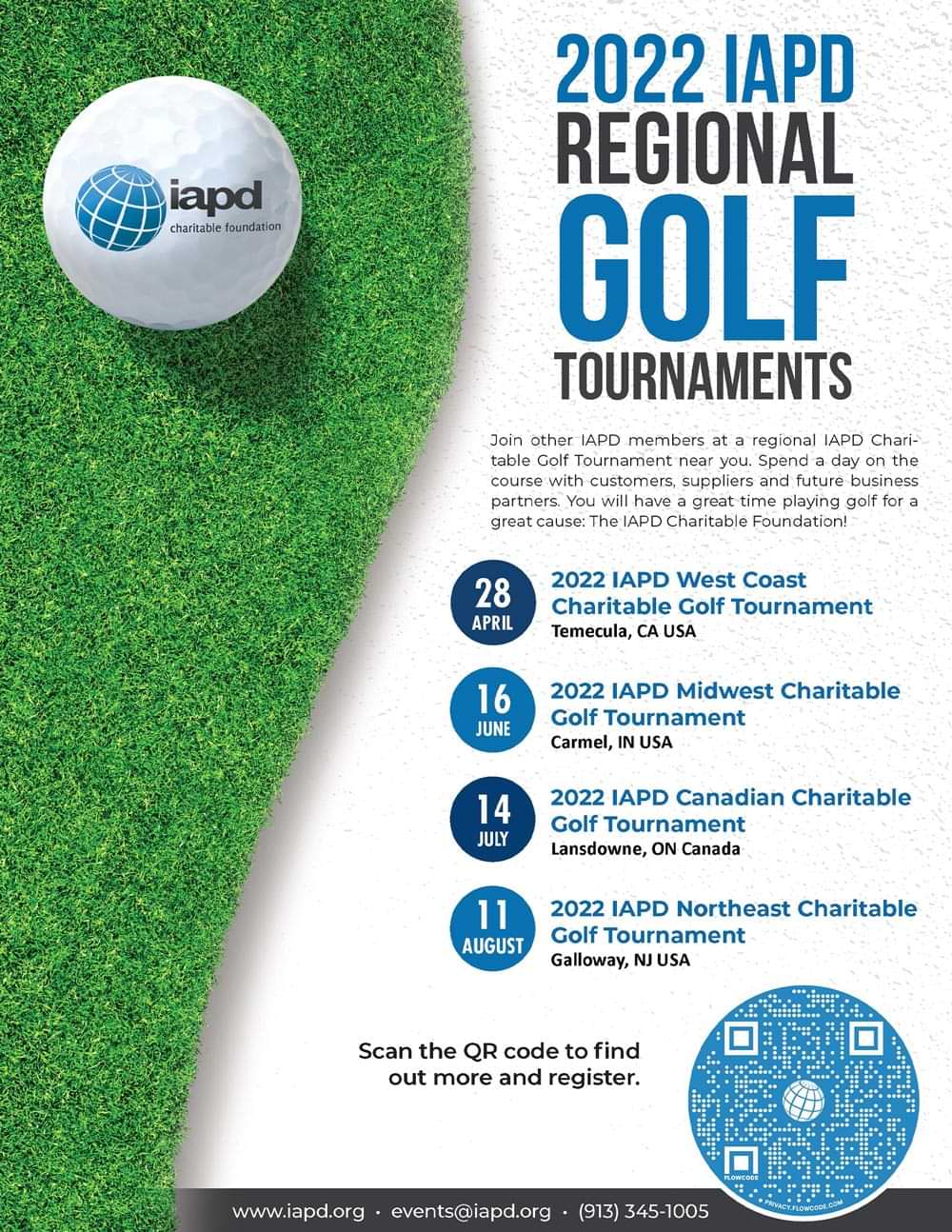

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

IAPD President

ost salespeople work hard to find the one idea that can give them the edge for a customer’s business … that one insight that will save their customers time and money. In many cases, the solution is to add value by selling them fabricated parts. Fabrication is a quick way to convert performance plastics from the sheet or rod form it has been produced in and supplying the customer with parts that have been converted to the end use. Depending on the fabrication needed, it could be as simple as cut-to-size, or as sophisticated as near net parts. From the customers’ point of view, even the simplest fabrication could make a huge difference. Some of us get creative to pull this off and, in the end, relationships and trust between the manufacturer, the distributor, the fabricator and the OEM are exactly what is needed to make it a success for all involved.

Editor’sPerspective

IAPD CEO

he past few years have certainly been disruptive to the industry. IAPD members went from trying to keep up with demand for clear sheet and other materials to prevent the spread of COVID, then there were hurricanes and the deep freeze in the Gulf Coast, driver shortages and the supply chain disruptions we hear about so frequently. Legislatively, the industry is facing anti-plastics sentiments that manifest themselves in draft legislation that crops up daily.

Polygrain is a weatherproof UV-resistant polymer sheet with a wood-like grain dispersed throughout the sheet and a wood texture on both sides. This material exceeds the limitations of wood and low-grade polymer materials for use outdoors during all seasons and in all climates. www.simonapolygrain.com.

Design and fabrication firm Dimensional Innovations developed and built the tallest 3D printed structure ever made using their Thermwood LSAM 1020 large scale additive manufacturing system. The result is the 93-foot tall commemorative Al Davis Memorial Torch in the Las Vegas Allegiant Stadium, the new home of the Raiders NFL team. What is not apparent is the amount of new, cutting-edge technology that was required to create this torch.

urbell Plastics, Inc. recently resumed its support of the non-profit Physicians for Peace (PFP) with a donation of cut-to-size PETG sheet after a brief disruption caused by the COVID pandemic. Since 2017, Curbell Plastics, Inc. has partnered with Physicians for Peace, a non-profit organization that works to strengthen delivery of surgical care to alleviate suffering and transform lives in under-resourced communities worldwide.

Due to travel restrictions, PFP halted in-person training events beginning March 2020. Once workshops were cleared to resume, Curbell Plastics, Inc. was able to help again by providing orthotic-grade PETG for the burn mask training event. PETG is frequently used for these masks and other burn management devices because of its excellent thermoforming characteristics, FDA compliancy, toughness, rigidity and optical clarity. In November 2021, PFP volunteer instructors met with therapists from seven Latin American countries to teach them how to fabricate rehabilitative transparent face masks for burn victims.

Curbell Plastics, Inc. donated several sheets of cut-to-size .06″ thick FDA-compliant PETG for the therapists to heat and drape over a positive mold of a patient’s face. The workshop trainers walked therapists through the process from casting a plaster mold of the patient to checking the mask’s fit against the face and making minor adjustments to obtain the most effective therapeutic treatment results.

The workshop is designed so the therapists can perform the entire process with commonly available tools such as ovens, heat guns and basic sculpting craft supplies. Generally, the most difficult item to source is the transparent plastic sheet. In addition to the PETG donation for training purposes, each attending therapist returned home with several cut-to-size sheets to continue practicing.

recently discovered a book titled Material Value: More Sustainable Manufacturing of Everything from Cell Phones to Cleaning Products by Dr. Julia Goldstein, a material science Ph.D., engineer and technical writer. This book appealed to me because, based on Dr. Goldstein’s background, it seemed like it would help me improve my ability to talk about sustainability.

Over the past five or six years, I have read books about various materials that compete with plastics, such as sand and glass, concrete, wood and paper products, ceramics, composites like fiberglass and carbon fiber, as well as books about various metals such as steel, aluminum, copper, brass and titanium. The more I learn about the properties and environmental costs of non-plastic materials, the better able I am to promote performance plastics and persuade people that plastics have unique features and benefits that no other materials can match.

As a distributor member on the IAPD Environmental Committee, as well as a member of the IAPD Board of Directors, I am vitally interested in the way plastics are viewed from a social and political point of view. There are regulatory and environmental forces at work in our society that cause some to see plastics as less environmentally responsible than other materials. I am doing my part to change this anti-plastics bias by learning just how sustainable our products and processes are, so we can then make the plastics industry increasingly more sustainable.

Material Value looks at the ways consumers and producers make decisions about material selection and how analyzing — and improving — the manufacturing process can drive us toward greater environmental sustainability.

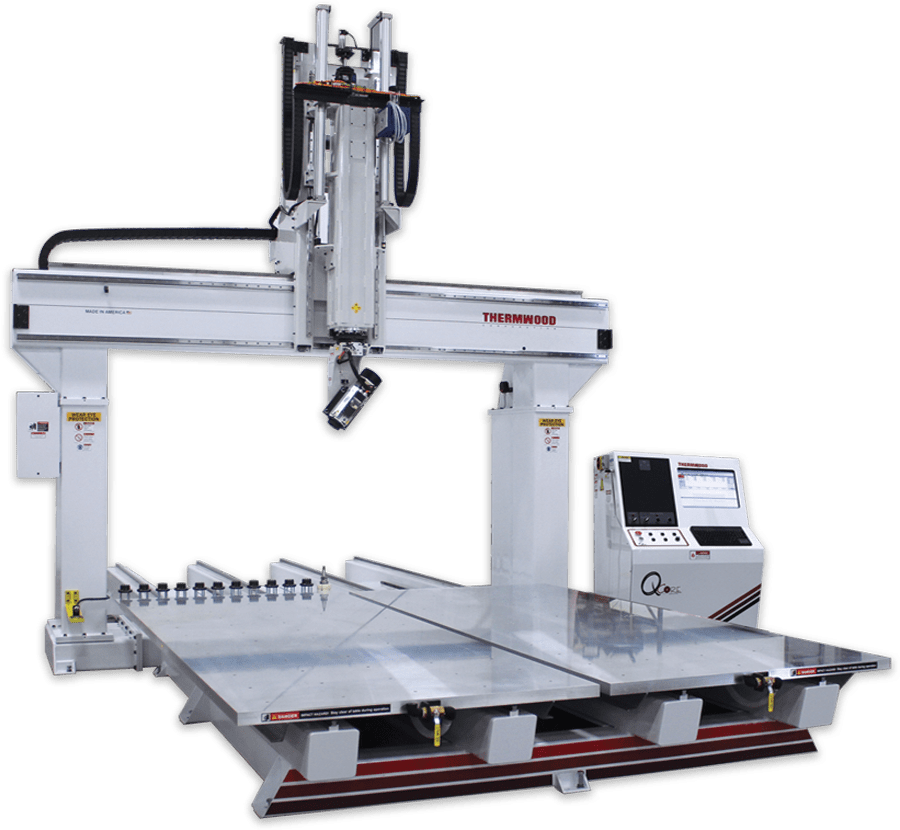

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

800-533-6901

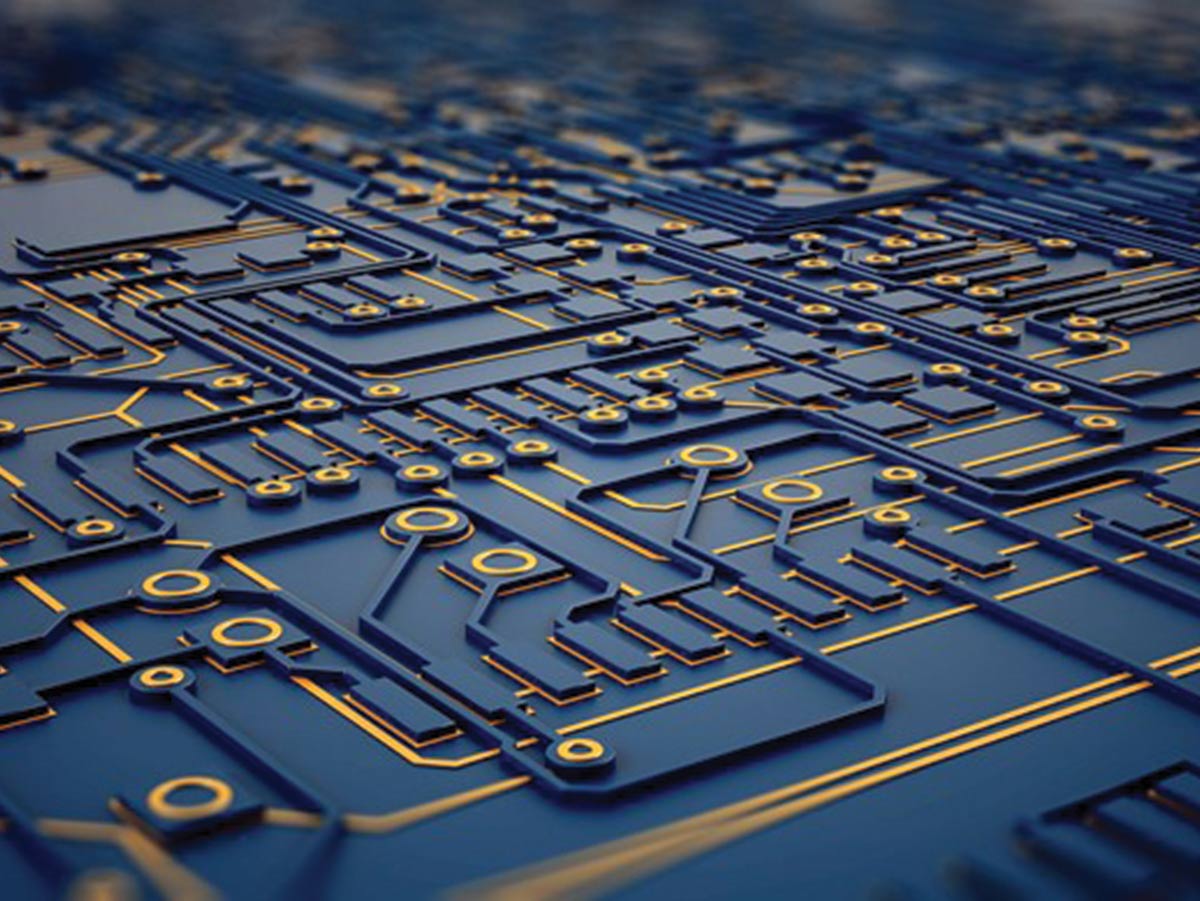

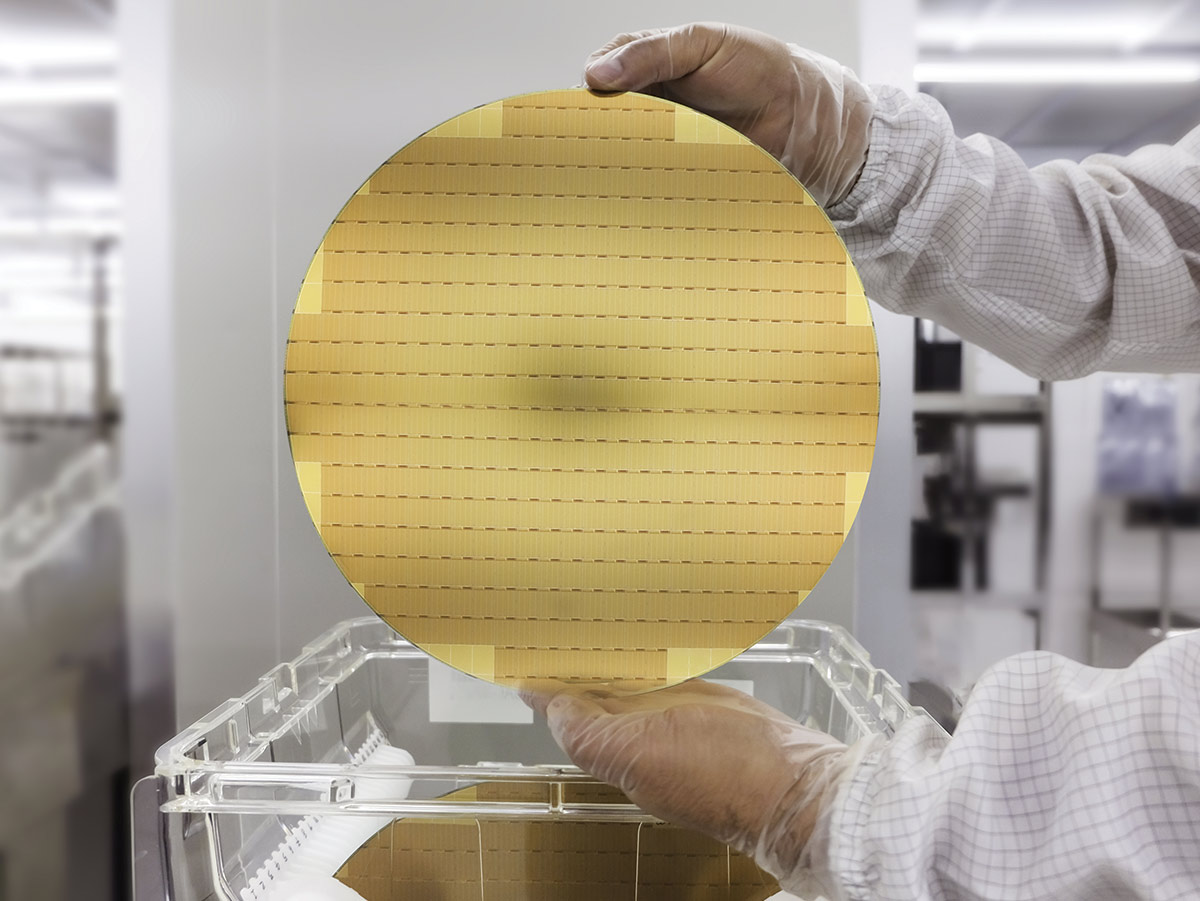

or more than half a century, plastic welding has proven to be a valuable technology employed in a wide array of industries. The continuous ingenuity of entrepreneurs around the globe have expanded the need for plastic welding technologies far beyond common uses such as tank manufacturing, ventilation and piping systems. A lesser known — but highly successful application benefitting from plastic welding — is the manufacturing of semiconductors.

If you’ve seen the news lately, you will know that the demand for semiconductors has soared in recent months. With inventories at all-time lows, many suppliers are determined to increase production capabilities in North America to prevent future shortages. That could mean an increase in the need for performance plastics used in manufacturing processes. Being a multibillion-dollar industry, governments and large corporations worldwide dedicate sizable financial resources to add and improve manufacturing capabilities.

Gears, machine parts, sprockets, star wheels, wear strips and more.

Gears, machine parts, sprockets, star wheels, wear strips and more.

here’s more than meets the eye when it comes to cutting acrylic. If you are not satisfied with the quality of the cut you are getting, read on for suggestions for how to improve it.

There are some nuances to consider. For example, did you know that cast and extruded acrylic cut quite differently? Or that tool selection and machine acceleration play a fundamental role in the quality of your finished product?

The keys to your success will be to set up your machine properly, choose the right material, select the correct tool and use the correct cutting strategy. This article will show you how.

- A strong, rigid base is essential. Purchasing a heavy-duty router allows you to couple a strong base with a stiff, solid gantry. This structure supports demanding processes, offering a robust and reliable unit while helping to minimize vibration and movement.

tock shapes are rarely used in their standard shape. Most of the time, the shape must be changed for the end use. Most of these end use shapes come from a drawing, a blueprint or a sketch. The print will show what the part is supposed to look like for use, not how it is going to get that way. That’s where machining and fabrication comes into play.

When machining or fabricating performance plastics, you must consider the properties of the material: Is it hard or soft, pliable or firm? Does it need to meet a certain temperature to be fabricated? These details will help you select the correct machinery and tooling to produce the end use part. If an incompatible method of fabrication is used with the material, it could lead to damaged machinery and tooling or a substandard part. Always refer to supplier guidelines for details about your selected material(s) because there can be limitations that are easy to overlook.

A band saw is useful for trimming formed parts or cutting irregular shapes. Usually hand operated, the operator moves the part in and out of the saw blade to trim off unused material.

erformance plastics have been a part of the medical industry for decades, often replacing other materials for better durability, easier sanitation and patient comfort. Seen in applications that range from storage to prosthetics to hospital bed frames, performance plastics have played a role in saving people’s lives every day. But what does it mean to the performance plastics industry that our medical system depends on using plastics?

Prior to COVID, it’s likely that most people didn’t think about the use of performance plastics in the medical field. However, starting in April 2020, businesses throughout the world scrambled to purchase as much clear acrylic and polycarbonate as they could find to keep their employees and customers safe. Everything from face shields to barriers required clear plastic. Nurses and doctors went from wearing their usual masks to wearing masks and face shields. Large corporations ramped up their production of personal protective equipment (PPE) and cottage industries sprung up to meet the demand.

Let’s start with the basic definition of medical-grade plastics: to be considered medical-grade, the plastics manufacturer must work under a physician’s license to pass the verification and validation requirements of regulatory agencies. Some of these requirements include having biocompatibility, temperature and impact and corrosion resistance and being able to withstand high wear and repeated sterilization. The most common thermoplastics used are polycarbonate (PC), polypropylene (PP) and polyethylene (PE).

- The U.S. economy will have solid growth; potential for economic growth later in the year is substantial with 3.5 percent GDP growth forecast for 2022.

- Equipment shortages will continue due to supply chain disruptions. Businesses will be likely to invest capital in maintaining inventories of crucial components and develop relationships with new suppliers to reduce impact of future disruptions.

- High inflation will be a major headwind for Main Street and the economy. The Federal Reserve has announced several interest rate hikes in 2022. It remains to be seen what impact, if any, interest rate increases will have on supply or demand.

- Positive growth in capital spending will continue. Equipment and software investment growth of 4.6 percent is expected.

- Equipment finance will play a significant role in economic growth. Based on historical precedent, more than half of equipment and software investment this year will be financed. In addition, inflationary pressures that drive equipment prices higher will make financing more desirable with payments spread out over time.

Widmann

“We are honored to have Larry join the CartierWilson team. Larry’s professionalism, market knowledge and work ethic precede him in the territory and we are excited to continue building strong relationships on the West Coast with distribution through our manufacturing partners,” said Vice President Alicia Spence.

Widmann lives in the Seattle, WA, USA area with his wife Missy and their son Nate, who is departing the nest for college in 2022. In his spare time, he enjoys swinging the golf club, hiking and traveling with family, reading a good page turner and watching movies.

Matt Nixon

Leo Lara

Yamily Almaguer was promoted to accounting manager just over a year after joining the A&C team. Since joining A&C, Almaguer has taken the lead with a new collection software and integrated it with the company’s new accounting database software, as well as introduced new techniques to improve efficiency within the accounting team. A&C is confident her leadership will help bring the company to new heights of success.