Polygrain is a weatherproof UV-resistant polymer sheet with a wood-like grain dispersed throughout the sheet and a wood texture on both sides. This material exceeds the limitations of wood and low-grade polymer materials for use outdoors during all seasons and in all climates. www.simonapolygrain.com.

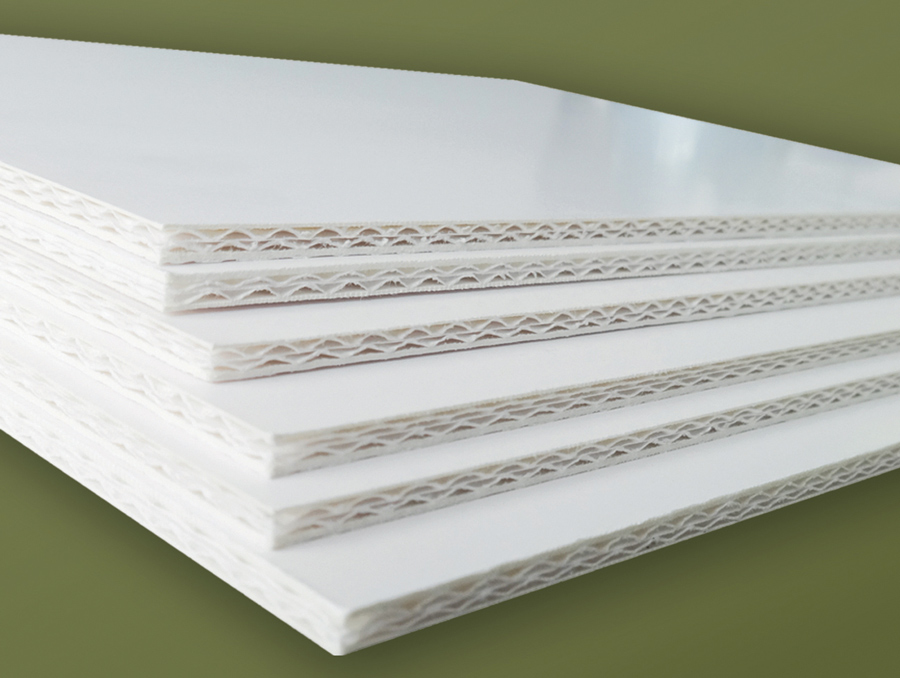

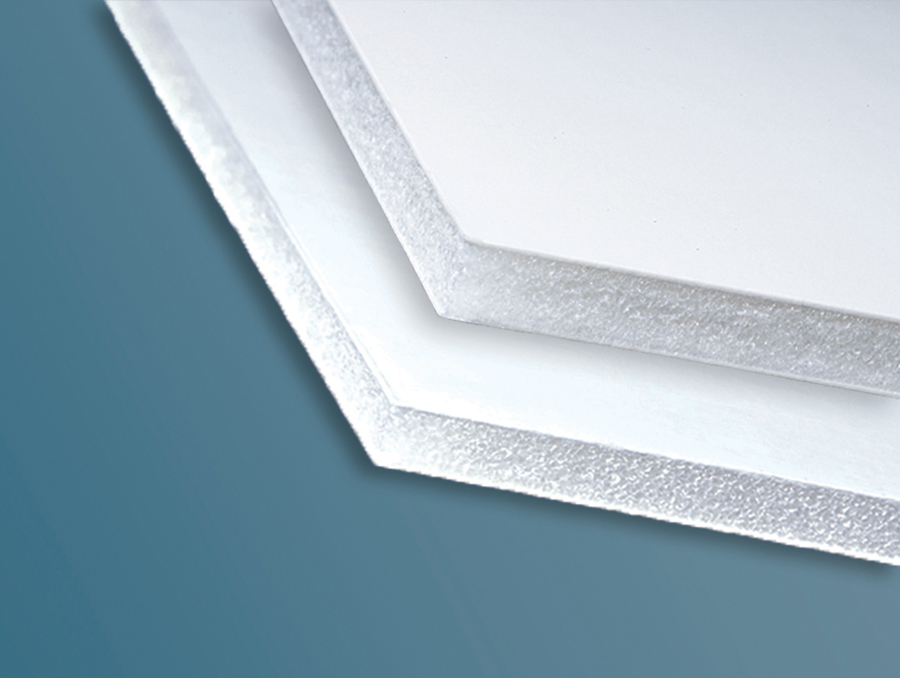

FOME-COR SIRIUS and DISPA SIRIUS graphic display boards were developed to exploit the capabilities of the HP PageWide XL Pro printers, which are designed to print to rigid substrates up to 10 mm thick and 40 inches wide at high quality and exceptional print speeds. FOME-COR SIRIUS and DISPA SIRIUS with ColorPRO Technology are custom engineered to work with these printers. By incorporating ColorPRO Technology, these rigid substrates conform to a strict set of specifications and use advanced technologies designed to deliver performance benefits such as:

- Higher black optical density and wider color gamut versus standard, uncoated papers.

- Sharper details, lines and text for clear, eye-catching graphics.

- Trouble-free, high-impact graphics with greater color saturation and lower ink consumption.

- Rapid ink absorption and rapid drying times enabling fast and easy printing.

“We at 3A Composites are excited to extend our FOME-COR and DISPA product collections with FOME-COR SIRIUS and DISPA SIRIUS featuring ColorPRO Technology,” said Chuck Kunze, director, product management and marketing, 3A Composites USA. “FOME-COR SIRIUS and DISPA SIRUS both are designed to provide enhanced image quality and faster printing speeds for print providers looking to expand their businesses through the adoption of this technology. We are proud to have partnered with HP — one of the world’s leading technology pioneers in printing — to develop these revolutionary new products.”

FOME-COR SIRIUS and DISPA SIRIUS are suitable for short-term promotional campaigns and can be used to create point-of-purchase and point-of-sale displays, menus, posters, hanging signs, window displays and tradeshow displays and exhibits. FOME-COR SIRIUS features a foam-centered core that will pillow when die cut to create a closed edge or unique three-dimensional embossing effects. As a 100 percent recyclable formed paper board, DISPA SIRIUS offers a green solution for short-term promotional campaigns; it is manufactured with 100 percent Forest Stewardship Council® (FSC®)-certified paper (FSC®-C169891).

Both FOME-COR SIRIUS and DISPA SIRIUS are available in B1standard sheet sizes (27.6″ x 39.4″/700 mm x 1000 mm). FOME-COR SIRIUS is available in both 3/16″ (5 mm) and 3/8″(10 mm) sheet thicknesses with white foam and bright white paper liners with ColorPRO Technology. DISPA SIRIUS is available in the 3.3 mm sheet thickness with bright white paper with ColorPRO Technology. www.3acompositesusa.com/display.

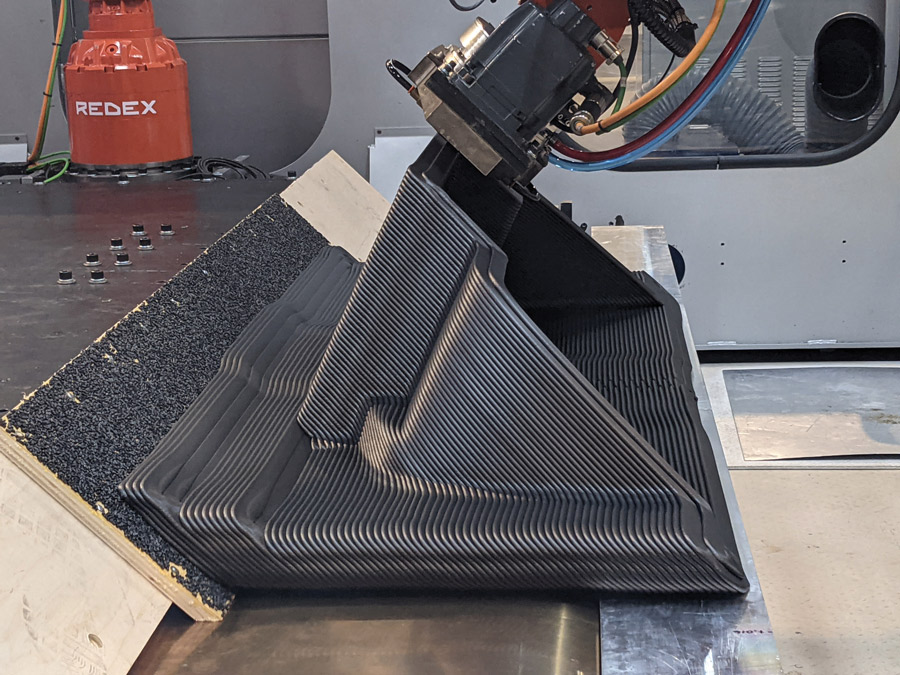

All print orientations use the complete LSAM print head including exclusive LSAM print features such as the patented compression wheel and thermal sensor layer automation. This helps maintain an even layer temperature throughout the print. LSAM automatically adjusts the individual layer temperature to provide for layer fusion.

LSAM machines are currently operating in daily industrial production with many existing systems equipped with VLP capability. The VLP option has been replaced with a VLP/ALP option on new machines to provide both vertical and angle layer print capability, in addition to the standard horizontal layer print. ALP can be added to machines operating in the field that already have the VLP option. If a machine was purchased without VLP, the entire new VLP/ALP print option can be added to most machines already in operation. It can be done in the field but is a bit more involved.

LSAM systems are available in sizes from 5 x 10 foot to 15 x 60 foot in a variety of configurations including print only and full print and trim. Print heads are available that can print thermoplastic composite material at rates from 200 pounds per hour to more than 500 pounds per hour.

These systems have a variety of features including a temperature-controlled compression wheel and automatic thermal layer speed control, both of which help assure the best possible fusion between printed layers. www.thermwood.com.

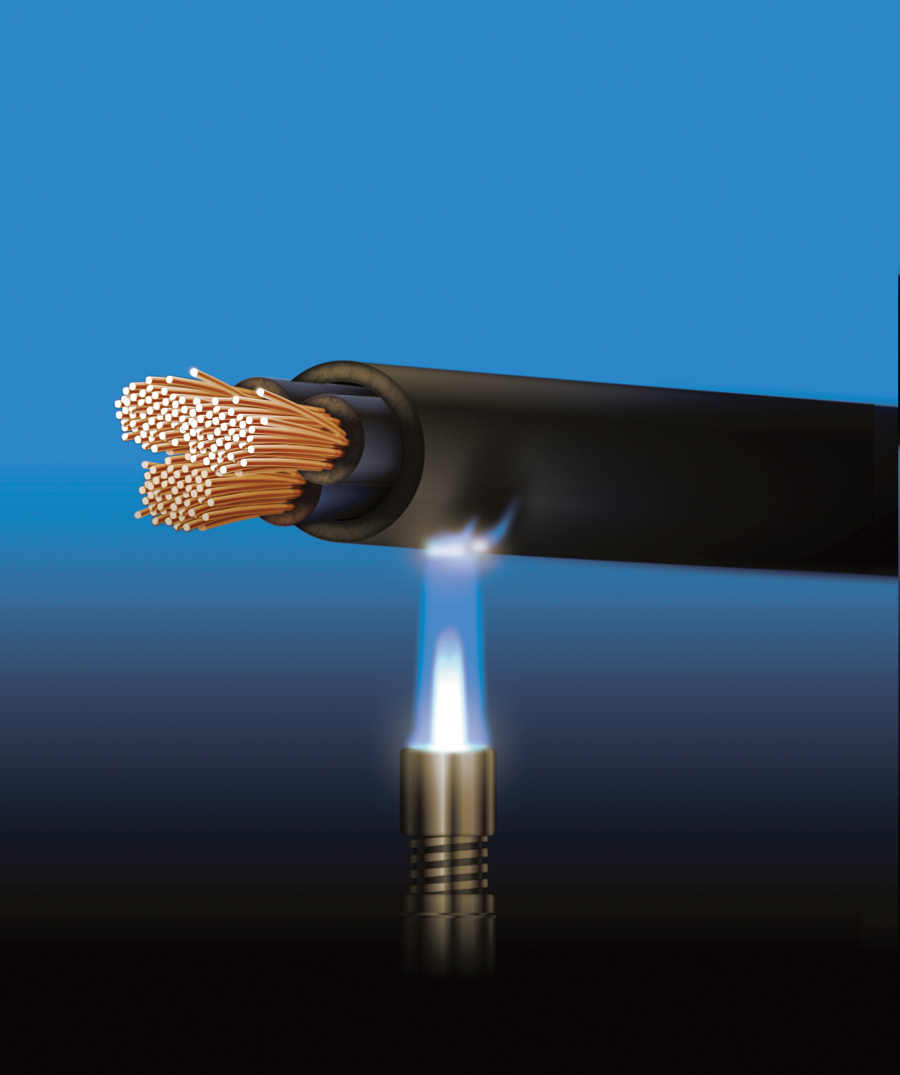

UV-stabilized ESTANE ZHF 90AM9 NAT 01 TPU is VDE 282, has UL 94 V-0 and UL 105°C temperature ratings. It is a differentiated solution with high mechanicals, excellent flame retardant properties and good surface aesthetics. It passes Cable Flame Test (according to UL-1581, Sec. 1061) on small diameter cables with a proven use case down to 8 mm. diameter. It is now possible for one material to combine the necessary key features that wire and cable applications require, to be durable and high performing. www.lubrizol.com.