Table

of

Contents

Best Practices

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of IAPD — The Performance Plastics Association are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of IAPD — The Performance Plastics Association is printed on paper with 10% post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

IAPD President

elcome to the 2025-2026 IAPD Membership Directory.

When I look through all the different types of companies that make up our membership, I think about the value that the association brings to each of you. The IAPD Board of Directors currently has a focus group studying membership trends and the value of IAPD, which was also the focus of our workshop at the recent Leadership Development Conference (LDC) in Dallas. While working on that, we thought it would be helpful to survey the current members of the board, committees, CIGs and task forces. We recently did this by asking a simple but powerful question:

Across all membership categories, your responses revealed consistent themes of connection, opportunity and growth.

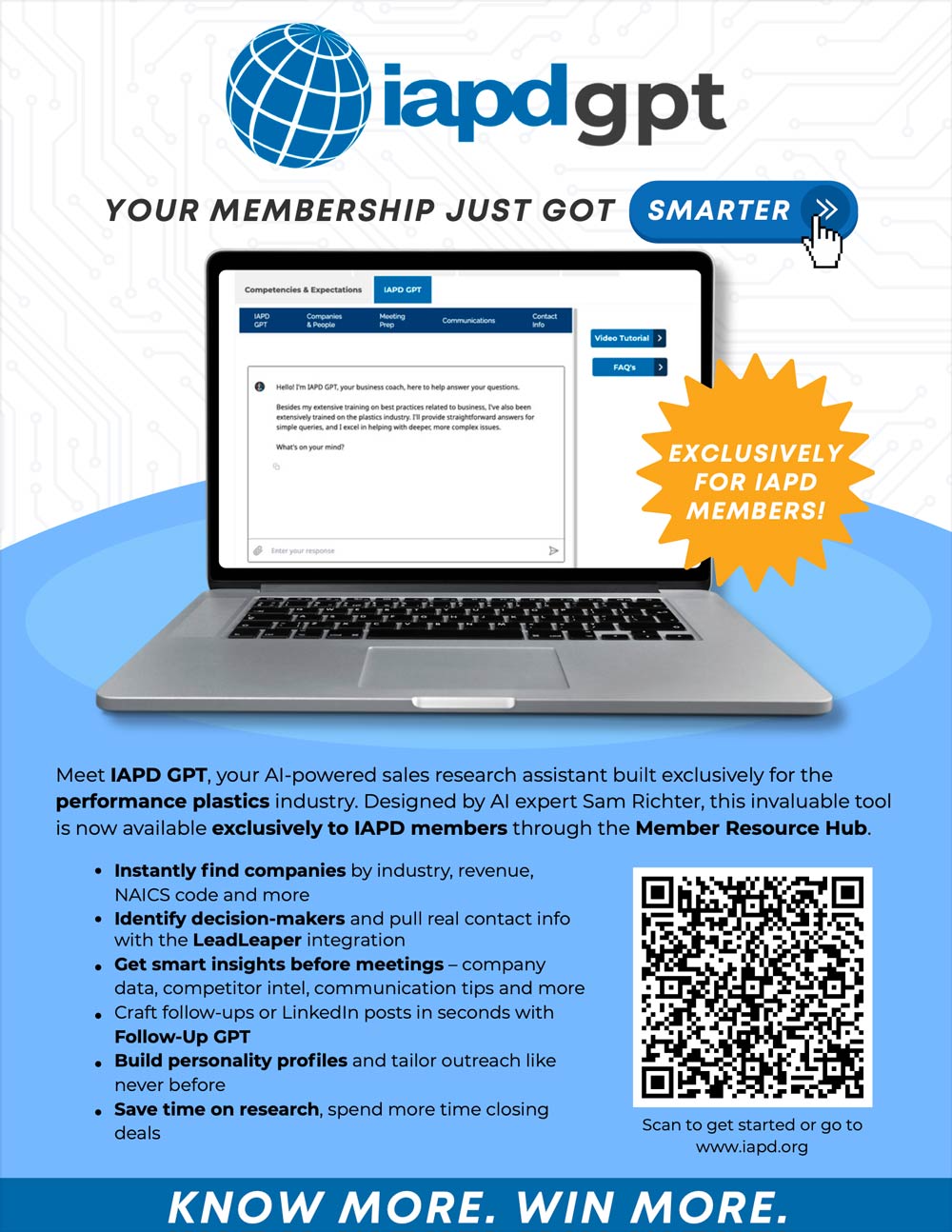

Your Membership Just Got Smarter: Introducing IAPD GPT

IAPD CEO

t the IAPD – The Performance Plastics Association, we know that membership has to mean something. In an increasingly competitive and fast-moving industry, our IAPD Board of Directors, committees task forces and staff are committed to ensuring that your IAPD membership delivers real value, practical tools and strategic advantages that help you grow.

That’s why we’re proud to announce the launch of IAPD GPT — a cutting-edge sales intelligence and business coaching tool available exclusively to IAPD members at no additional cost. This AI-powered assistant represents a major leap forward in how our members can gather insights, prepare for sales meetings, connect with prospects and close deals — faster and smarter than ever before.

This isn’t just a value-added benefit. It’s a member-only advantage.

Showcase

Röchling Industrial’s Polystone® G (HDPE) Grey is being used in pill slats for pharmaceutical machinery, supporting high-speed tablet sorting, counting, and packaging operations.

Pill slats, also known as tablet slats, are precision-machined plates with cavities designed to hold individual pills as they move through automated packaging lines. Polystone HDPE is selected for this application due to its FDA compliance, low coefficient of friction and good dimensional stability, which help protect tablets from damage and ensure accuracy in counting and placement.

These components play a critical role in ensuring efficiency and product integrity in pharmaceutical production environments. www.roechling.com/us/industrial.

News

CELTEC White by PLASKOLITE.

CELTEC White is the latest addition to the CELTEC family, which includes five product variations offering different colors, textures and performance characteristics. The new sheet is engineered for digital printing, offering a refined white point to support vibrant, true-to-color graphics. It features consistent density, is available in multiple sizes and thicknesses and incorporates up to 30% recycled content from post-industrial and post-consumer sources.

Recommended applications include signage, point-of-purchase displays, dimensional letters, store fixtures, exhibits, kiosks, wayfinding and monument signs. The sheet is designed for ease of fabrication, painting and laminating. www.plaskolite.com.

Innovation

Innovation Quality

Quality Worldwide Distribution

Worldwide Distribution

The Best Resources for Regulatory Guidance in Today’s Fast-changing Climate

n the world of rapidly changing regulations, who can I trust to keep me up-to-date? The IAPD Environmental Committee has come together to share with you their favorite trustworthy resources. The sites and sources discussed below are not an exhaustive list by any means, but certainly a great place to start.

What Makes an ESG Website Reliable?

- Transparency of data sources and methodology

- Regularly updated information

- Independence and lack of bias

- Alignment with recognized standards (e.g., GRI, SASB, TCFD)

Distributor Best Practices

e’ve all been there — sitting in a meeting that easily could’ve been handled over email. Time is one of the most valuable resources we have, especially in the fast-paced world of plastics sales. For manufacturers, distributors and reps alike, every meeting should be intentional, productive and rooted in strategy.

Shuttershock.

Distributor Best Practices

he talent landscape in the plastics distribution and manufacturing industry is changing rapidly. As seasoned professionals retire and the competition for skilled individuals from other industries intensifies, it is more important than ever for organizations to implement a proactive talent management strategy. Companies need a realistic and scalable method to assess their talent and prepare future leaders. The 9-box grid is a simple and effective solution.

Wide Variety of 3 & 5 Axis Machining Centers for Plastic and Composite Trimming

MULTIPURPOSE 45

Heavy-duty three axis designed for composites, plastic sheets, aluminum, cabinets, wood and nested base panels. Available in either single or dual spindles with optional rotary axis.

Table Sizes: 5’x’5, 5’x10’, 5’x12’, 6’x12’ and 7’x12’

MULTIPURPOSE 63

Large bed axis CNC router with moving bridge & stationary table designed for two and three dimensional machining of large composite parts & three dimensional patterns. Available in either a three or five axis configuration.

Table Sizes: 5’x10’ (1.5m x 3.0m), 5’x20’ (1.5mx6.0m), 5’x40’ (1.5mx12.0m), Table Extensions available up to 100’ (18m)

LFM

Large bed 3 axis CNC router with moving bridge & stationary table designed for two and three dimensional machining of large composite parts & three dimensional patterns.

Table Sizes: 10’x20’, 10’x30’, 10’x45’ additional sizes up to 80’.

MULTIPURPOSE 67

Versatile five axis available with either single or dual moving aluminum tables used for plastic trimming, patterns, molds and non-ferrous metals.

Table Sizes: Single Table – 5’x’5, 5’x10’, 10’x5’, 5’x12’, and 7’x10’ Dual Tables – 5’x5’, 5’x10’ and 5’x12’

MULTIPURPOSE 90

Heavy-duty, high-speed trimming and pattern machining, available in single or dual moving aluminum tables.

Table Sizes: Single Table – 5’x’5, 5’x10’, 10’x5’

MULTIPURPOSE 70

Designed for aerospace and composite applications utilizing large/heavy fixtures.

Table Sizes: 10’x5’, 10’x10’, 10’x15’, 10’X20’

MULTIPURPOSE 77

Heavy-duty, high-speed contained system for the machining of large aerospace and composite materials.

Table Sizes: 5’x10’, 10’x10’, 10’x20’, 10’x30’, 10’X40’ and up in 10’ increments in length

Made in USA

800-533-6901

Distributor Best Practices

achine shops will often ask distributors to provide pricing on plastic stock shapes that meet various external specifications. Examples include ASTM, ISO, MIL and SAE AMS specs. Responding to these inquiries with detailed and accurate quotations is a great way to build credibility with customers and grow sales. Additionally, supplying plastics that conform to the required specifications ensures that the correct materials will be put into service, reducing the chance of costly part failures.

Some documents such as MIL specs are available online at no charge. Others such as ASTM and SAE AMS specifications can be obtained from the publishing agency for a nominal fee. Material specifications are lengthy by design since they include granular detail about the properties and composition of the plastic. That being said, spending 20 minutes reviewing a spec is time well invested prior to sending a quotation to a customer.

Distributor Best Practices

lastic coatings — They’re not the most titillating subject at first glance. Coatings are not a commodity like acrylic, polycarbonate, nylon, Delrin or UHMW, so they’re not as easy to sell as common plastics. As a distributor you might be asking yourself, “So why would I bother learning about plastic coatings?” This article will open your eyes to the major categories of coatings, how easy they are to sell and the money to be made.

First and foremost, what do coatings do? Simply put, they change the surface of the substrate. A coated surface is more durable and longer lasting compared to an uncoated surface. Additionally, coated products are easy to clean with a variety of common cleaners. Coating a sheet of plastic transforms it from a commodity with a low gross profit to a niche item with a higher GP.

People &

Places

-

Chris Cain

Asahi/America, Inc. announces the addition of Chris Cain to its outside sales team as district sales manager.

Cain joined Asahi/America on February 24, 2025 as district sales manager for the Southeastern sales region comprised of Florida and Georgia. Cain brings over 25 years of experience in life support systems operations for aquariums and zoos, making him a valuable addition to Asahi/America’s sales team. In his new role, Cain will be responsible for supporting distributors and customers within his territory, offering product recommendations, support and project assistance.

Before joining Asahi/America, Cain worked at Loggerhead MarineLife Center in Juno, FL as the vice president of facilities and animal husbandry. Prior to Loggerhead MarineLife Center, he worked at Shark Reef Aquarium at Mandalay Bay in Las Vegas, NV for over 20 years as a journeyman plumber during construction, then in the facility’s Life Support Systems division. His vast knowledge of valve and piping systems in these life support system applications will assist distributors and engineers in sales and specification efforts of Asahi/America’s full catalog of valves, actuators and piping systems.

-

Jason Susnjara

Jennifer WattThermwood Corporation announces the promotion of two key executives.

Jason Susnjara has been promoted to president of Thermwood Corporation, succeeding David Hildenbrand, who recently retired after 47 years of distinguished service. With more than 30 years at Thermwood, Susnjara has held a wide range of leadership roles across multiple departments, gaining a comprehensive understanding of the company’s operations.

Since 2019, he has served as executive vice president, where he played a key role in guiding Thermwood’s strategic direction and growth. He also serves on the company’s Board of Directors.

Jennifer Watt has been promoted to executive vice president of Thermwood Corporation. Since 2019, Watt has served as the company’s chief legal officer, where she has led Thermwood’s legal and corporate governance efforts with distinction.

Flat Stock

Sheet Stock

Profile Shapes

Fabrication

3311 Enterprise Road

Fort Wayne, IN 46808

Fabrication

SERVICES SHOWCASE

Fabrication Services Showcase contains paid listings of companies with fabrication services, products and machinery that cater to the performance plastics distribution industry. IAPD does not endorse nor make recommendations in regard to the companies supplying their services. For details and pricing information to include your company in this Fabrication Services Showcase, contact Jessica Bokath, IAPD’s director of sales, at (913) 345-1005 or email jbokath@iapd.org.

CNC Equipment

Sawing, trimming, drilling, polishing, measuring or 3D processing — no matter what techniques are involved, Stiles has the CNC technology to get it done. Their machining solutions can be custom-configured to your specific needs. From productivity and high precision, to energy and material savings, Stiles provides proven CNC options for plastics processing. For more information, contact info@stilesmachinery.com or visit www.stilesmachinery.com.

Vortex Tool Company, Inc. designs and manufactures a wide variety of standard and custom high-performance router and insert cutting tools for the woodworking and plastics industries, and provides retipping and sharpening services for all makes and models. www.vortextool.com, phone (800) 355-7708.

REP BUSINESS

Exchange

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Astari Niagara Internassional, pt. • (62) 21-5097-9797 • www.astariglobal.com

Atlas Saw & Tool • (888) 484-1488 • www.shop.atlassaw-tool.com

Craftech Industries, Inc. • (518) 828-5001 • www.craftechind.com

Ensinger • (800) 243-3221 • www.ensingerplastics.com

GEM Plastics • (706) 779-7791 • www.gemplastics.com

Hudson Extrusions, Inc. • (800) 837-6015 • www.hudsonextrusions.com

King Plastic Corporation • (800) 780-5502 • www.kingplastic.com

Lustercraft® Plastics • (800) 362-2492 • www.lustercraft.com

Palram Americas, Inc. • (800) 999-9459 • www.palramamericas.com

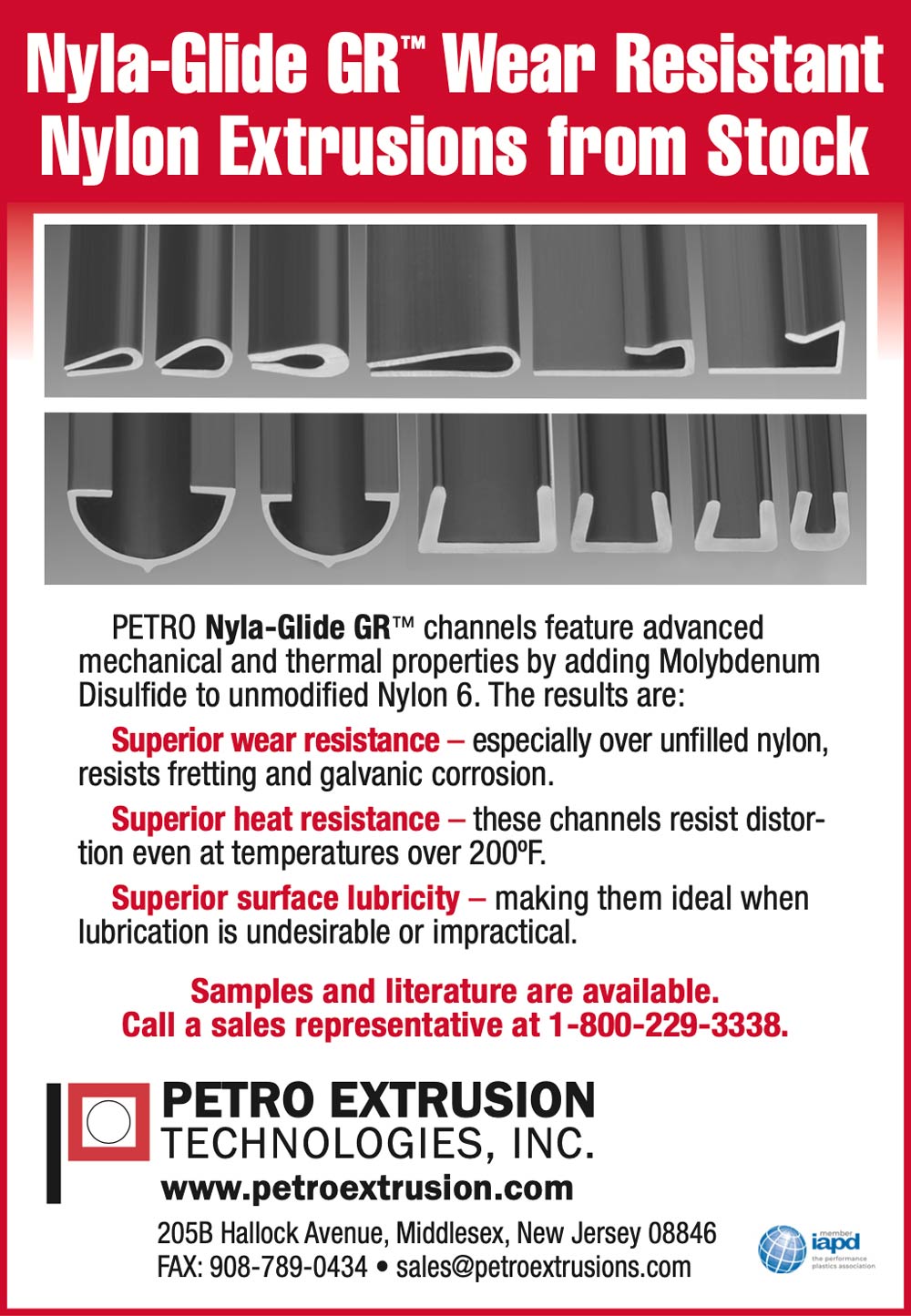

Petro Extrusion Technologies, Inc. • (800) 229-3338 • www.petroextrusions.com

Pexco LLC – Corporate Office • (770) 343-4095 • www.pexco.com

PLASKOLITE • (800) 848-9124 • www.plaskolite.com

Polymer Industries • (877) 765-9637 • www.polymerindustries.com

Rowmark LLC • (877) 769-6275 • www.rowmark.com

IMA Schelling Group, USA • (919) 544-0430 • www.imaschelling.us

Thermwood Corporation • (800) 533-6901 • www.thermwood.com

Wegener Welding, LLC • (800) 647-3061 • www.wegenerwelding.com

BoardofDirectors

Michelle Betz • Alro Plastics • Jackson, Michigan, USA

Jeff Burke • Curbell Plastics, Inc. • Orchard Park, New York, USA

Katie Clapp • A&C Plastics, Inc. • Houston, Texas, USA

Chris Corona, Executive Committee • CartierWilson LLC • Solon, Ohio, USA

Bryan Davis • Ensinger • Washington, PA, USA

Peter DelGado, President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Stephen Garmon • Primex Plastics Corporation • Richmond, Indiana, USA

Hayden Hess • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Advanced Materials • Sacramento, California, USA

Jim Richards, Vice President • PLASKOLITE • Columbus, Ohio, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Alicia Spence • SIMONA AMERICA Group • Atlanta, GA, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

The International Association of Plastics Distribution

6734 West 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Advertising Sales

Jessica Bokath

jbokath@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Keith Hecthel • Curbell Plastics, Inc. • Orchard Park, New York, USA

Courtney Kincaid • Polymershapes • Charlotte, North Carolina, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions •

Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Publishing

Headquarters

The International Association of Plastics Distribution

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Advertising Sales

Jessica Bokath

jbokath@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Editorial Committee

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Keith Hecthel • Curbell Plastics, Inc. • Orchard Park, New York, USA

Courtney Kincaid • Polymershapes • Charlotte, North Carolina, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions •

Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA