Table

of

Contents

- All IAPD Members Geographical Listings

- Plastics Material and Shapes Guide

- Resin & Semi-Finished Plastics Manufacturers

- Equipment & Service Providers

- Plastics Trade Names Directory

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

building relationships is the cornerstone of our success

IAPD President

he one resounding theme of my presidency has been ensuring our members have understood the major skill that I felt would get our companies and association through any major hurdles that comes our way: relationship building. I passionately champion the importance of building relationships within the performance plastics industry. IAPD offers an incredible tool that we can leverage in our industry relationships through strategic sourcing, by using the Source Guide included at the back of this magazine as a road map to do just that.

In today’s globalized world, we have endless options for sourcing plastics and materials. The saturation of the industry makes it more critical than ever to find the right supply sources. Our industry relies on the expertise and quality of our suppliers, and the relationships we build with them can have a profound impact on our success. When we utilize the Source Guide to its fullest extent we can easily connect, not just as customers and suppliers, but as collaborative partners in our journey toward excellence.

Editor’sPerspective

Imperfect timing, ideal environment

IAPD Director of Marketing and Content

rial by fire” and “drinking from a fire hose” are two familiar phrases that have been thrown around in my first few weeks at IAPD. Both ring true to my experience so far, but a more accurate description of my experience came from IAPD CEO Susan Avery when she said that this was “both the best and worst time to start this role.”

I began my time with IAPD just two weeks shy of our 67th IAPD Annual Convention + connecX in San Diego, CA, and I hit the ground running as a whirlwind of information and introductions were thrown my way. I’ve soaked up as much as I could and asked as many annoying questions as I could manage during the opportunities, I’ve had to meet with you. Thankfully, everyone has been gracious and enthusiastic to equip me with the intel I need to begin mapping out my goals as your new director of marketing and content.

AGRULINE offers excellent durability, resistance to corrosion, seismic and weathering resistance and leak-proof joints — all key factors when designing pipelines for a sustainable future.

Supporting the DIPS standard allows AGRU America, Inc. to deliver pipes to more projects and regions that continue to rely on that sizing system.

“Adding the custom tooling to manufacture pipes for the DIPS standard shows AGRU’s commitment to growing its piping business and meeting the needs of its customers in the United States,” says Natasha Arguijo, head of the AGRULINE business unit. “As we complete more successful projects, I expect our capabilities to grow in tandem.”

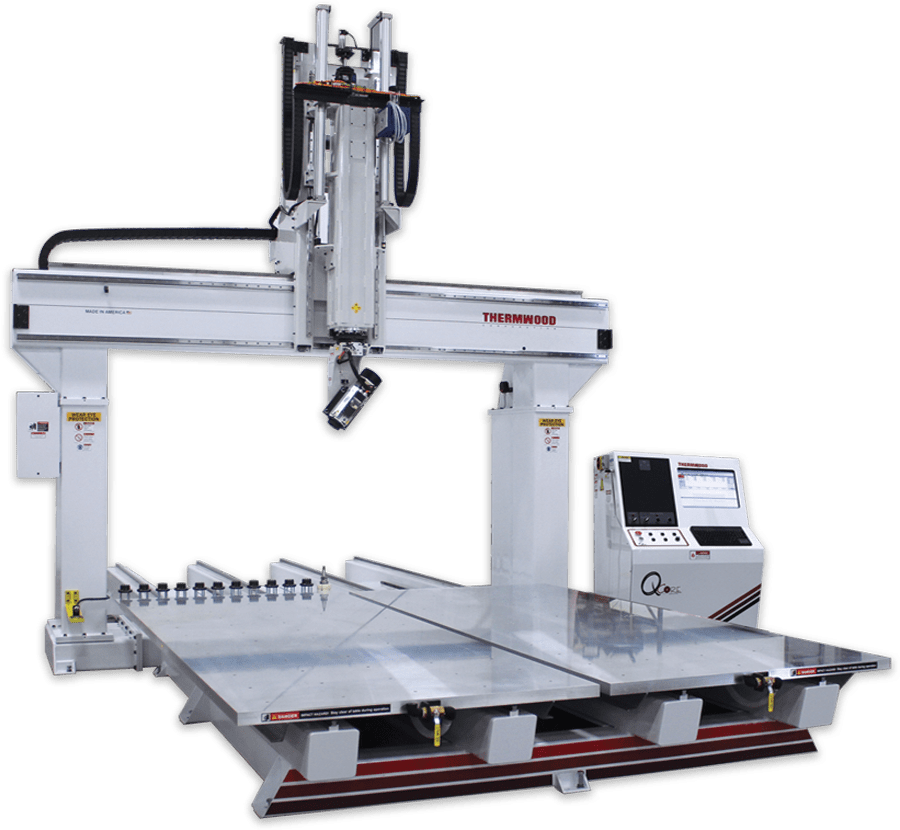

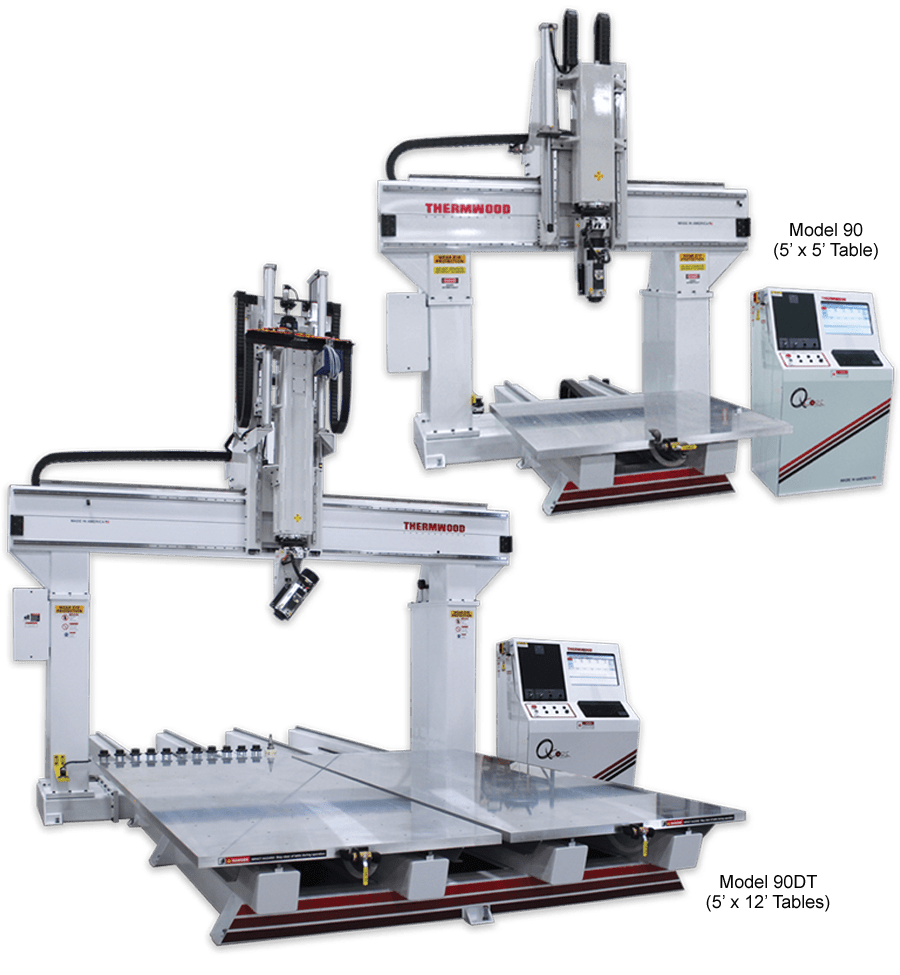

Thermwood Model 90

Heavy Duty 5 Axis CNC for

Three-Dimensional Applications

(5’ x 5’ Table)

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

(5’ x 12’ Tables)

800-533-6901

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

800-533-6901

The Marine Donut is the world’s largest thermoplastic structure made from 600 metric tons of PE100-RC sheet and pipes by AGRU, America, Inc. Credit: Bluegreen AS

The Norwegian company Bluegreen AS has successfully implemented a groundbreaking aquaculture project, the Marine Donut. This closed floating fish farming system, made from the highly crack-resistant plastic PE 100-RC, was installed on a salmon farm owned by SalMar in Norway. This innovative facility, whose PE 100- RC components were supplied entirely by AGRU America, Inc., could be the beginning of a new era of sustainability in salmon farming.

With an outer diameter of 180 feet, a height of over 55 feet, and a total weight of around 660 tons, the Marine Donut is the world’s largest thermoplastic structure. The unique design of this floating fish farm has the potential to revolutionize salmon farming.

Developing the Social Capital of a Diverse Workforce:

ACCELERATING INCLUSIVE CAREER PROGRESSION IN PERFORMANCE PLASTICS ORGANIZATIONS

Article four in the DEI+B series by the IAPD Diversity Equity and Inclusion Task Force

hen plastics professionals are encouraged to achieve excellence through well-designed career development plans, IAPD member companies benefit from increased productivity, higher employee job satisfaction, reduced turnover and enhanced financial results. Additionally, plastics organizations that focus on the professional development of their employees tend to have more effective succession planning.

When designing career progression plans for employees, it is important to consider two aspects of professional development: building an individual’s human capital and building their social capital. Human capital is defined as a person’s knowledge, skills and experiences that can be employed to achieve productive work. Examples of human capital development include product training, computer skills training, leadership skills development and sales training. However, human capital development by itself is insufficient to prepare a person for career advancement. Effective career progression plans must also consider social capital development, which focuses on building an employee’s professional network.

Social capital is defined as the power that resides in the relationships between people that can be used to get work accomplished. Having an effective network benefits the careers of plastics professionals in a number of ways including:

EnvironmentalCorner

IAPD CEO

he topic of sustainability is not something new for the performance plastics industry or within IAPD. We have focused on it for the last 14+ years when IAPD first launched its Environmental Committee. The industry has evolved over the years, and technological advancements in the recycling of plastics has helped our industry improve the amount of materials that we divert from landfills.

When IAPD first started its Environmental Committee and initiatives, we sought to benchmark where the performance plastics industry was on recycling its internally generated scrap material. Additionally, we sought to capture other environmental initiatives that our member companies were executing and measure their progress over time. 13 years later, IAPD is still having difficulty collecting and measuring this basic data from our industry.

While our industry is still working on dealing with the internally generated scrap that we produce, the rest of the world has moved on and not only expects more from us, but needs more from us.

Places

Russell

In this new role, Russell will bring his decades of industry experience to support Norplex-Micarta’s mission. Primarily focused on new applications and materials, Russell will have the support of facilities globally, which are staffed with development engineers, test facilities and unique capabilities to produce high performance composite materials at scale.

“Mark is an accomplished professional and a respected member of the composite industry. I am excited to have him on the team to bring to market many new materials and approaches that Norplex has been developing over the last few years. These are exciting times for the composites industry, and Mark will be a great resource for us and our customers,” said Dustin Davis, director of sales and business development of Norplex-Micarta.

Russell has decades of sales and application development experience at OEMs such as Applied Materials and Parker Hannifin as well as at material manufacturers such as Freudenberg and Mitsubishi. For the last 12 years, Russell had been at Atlas Fibre, most recently serving as its general manager.

Colton Glenn

FABCO PLASTICS WHOLESALE LIMITED CELEBRATES 60 YEARS OF COURAGE, SERVICE AND GROWTH

abco Plastics Wholesale Limited, founded in 1962, has a 60-year-long history defined by its unique founding story and numerous acts of service to their community; and it all began in a garage.

Fabco Plastics Wholesale Limited Founder Meinhard Kehren.

After enduring years of a dangerous, transient life during World War II, the boys and their aunts made their way back to their family home in Langenfeld, Germany, a town just six kilometers from Kehren’s birthplace. With the war ending, Kehren was able to complete his high school education and enter the workforce as a carpenter’s apprentice.

After completing his apprenticeship, Kehren found his job to be tedious and yearned for more. He wanted to travel to a new country in search of a new job, but as a German citizen he faced barriers to immigrating to many countries. Kehren left his job and spent his savings on travel, in hopes of finding his next home.

Fabrication Services Showcase contains paid listings of companies with fabrication services, products and machinery that cater to the performance plastics distribution industry. IAPD does not endorse nor make recommendations in regard to the companies supplying their services. For details and pricing information to include your company in this Fabrication Services Showcase, contact Dave Blackhurst, IAPD’s Sales Executive, at (913) 345-1005 or email dblackhurst@iapd.org.

The smart choice for

many high abuse

application

Available in colors: Black and White

The smart choice for many high abuse application

Available in colors: Black and White

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Alro Plastics • (517) 787–5500 • www.alroplastics.com

Artek, Inc. • (800) 762-6808 • www.artek-inc.com

Champion Fiberglass • (281) 655-8900 • www.championfiberglass.com

Ensinger • (800) 243-3221 • www.ensingerplastics.com

Fluoro-Plastics • (800) 262-1910 • www.fluoro-plastics.com

Gallina USA, LLC • (888) 463–3342 • www.gallinausa.com

Hudson Extrusions, Inc. • (800) 837-6015 • www.hudsonextrusions.com

King Plastic Corporation • (800) 780-5502 • www.kingplastic.com

Mitsubishi Chemical Group • (610) 320–6600 • www.mcam.com

Norplex–Micarta • (563) 864–7321 • www.norplx–micarta.com

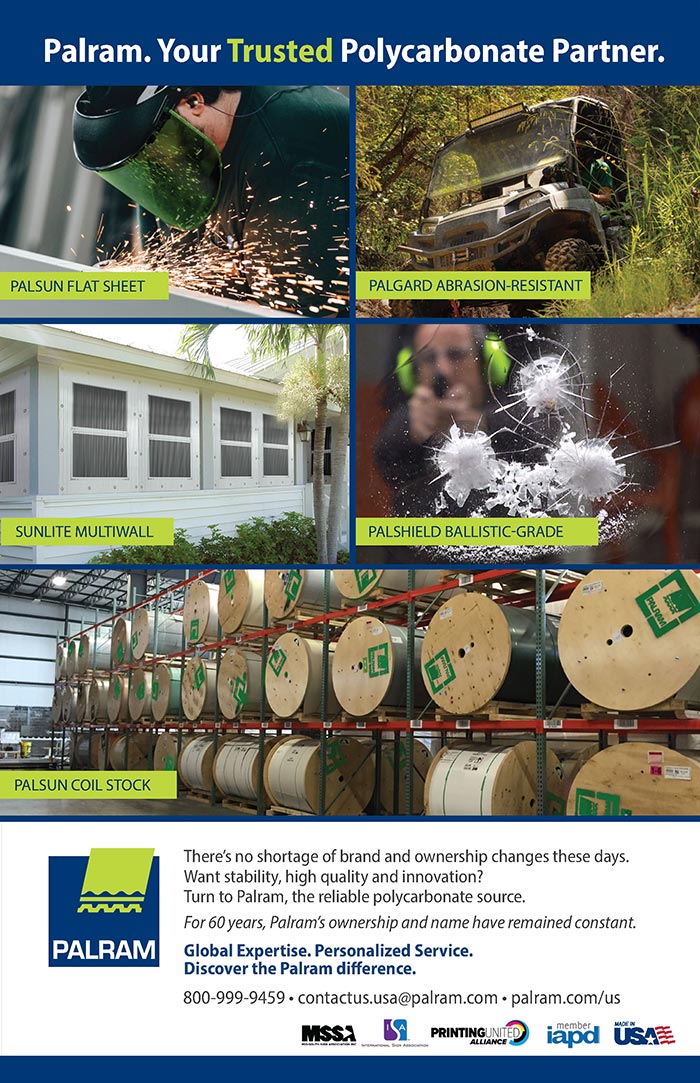

Palram Americas • (800) 999-9459 • www.palramamericas.com

Petro Extrusion Technologies, Inc. • (800) 229-3338 • www.petroextrusions.com

PLASKOLITE • (800) 848-912 • www.plaskolite.com

Polymer Industries • (877) 765-9637 • www.polymerindustries.com

Rowmark LLC • (800) 243–3339 • www.rowmark.com

Schelling America, Inc. • (919) 544-0430 • www.imaschelling.us

Spartech • (800) 677–4338 • www.spartech.com

Thermwood Corporation • (800) 533-6901 • www.thermwood.com

Wegener Welding, LLC • (800) 647-3061 • www.wegenerwelding.com

BoardofDirectors

Bill Barth, Executive Committee • Piedmont Plastics • Charlotte, North Carolina, USA

Karen Brock–Amoah • SIMONA Boltaron • Newcomerstown, Ohio, USA

Jeff Burke • Curbell Plastics, Inc. • Orchard Park, New York, USA

Chris Corona • CariterWilson LLC • Solon, Ohio, USA

Peter DelGado, Vice President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Dale Delmage • Redwood Plastics and Rubber • Langley, BC, Canada

Stephen Garmon • Primex Plastics Corporation • Richmond, Indiana, USA

Hayden Hess • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Advanced Materials • Sacramento, California, USA

Richard Miller • Braskem • Philadelphia, Pennsylvania, USA

Deborah Ragsdale, President • Polymer Industries • Henagar, Alabama, USA

Jim Richards, Executive Committee • PLASKOLITE • Columbus, Ohio, USA

Drew Schwartz, Executive Committee • Colorado Plastics • Louisville, Colorado, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

The International Association of Plastics Distribution

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE

savery@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Director of Marketing & Content

Randy Skach

rskach@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Junior Copywriter & Editor

Sara Marquardt

smarquardt@iapd.org

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Publishing

Headquarters

The International Association of Plastics Distribution

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE

savery@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Director of Marketing & Content

Randy Skach

rskach@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Junior Copywriter & Editor

Sara Marquardt

smarquardt@iapd.org

Editorial Committee

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group – Engineered Shapes & Solutions • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA