Table

of

Contents

Special Advertising Supplement

Special Focus: Semiconductors

Cover art by Sara Marquardt, IAPD Content Manager

Performance Plastics: A Publication of IAPD — The Performance Plastics Association is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for nonmembers is $149. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of IAPD — The Performance Plastics Association are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of IAPD — The Performance Plastics Association is printed on paper with 10% post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

Strategy in Action:

This article is adapted from Peter DelGado’s outgoing president’s speech, delivered at the Wednesday General Session during the 69th IAPD Annual Convention in Chicago, IL, USA, October 1, 2025.

Outgoing IAPD President 2023–2025

o say that our industry and the overall business climate was been interesting this year is an understatement. While we are all under pressure to produce results in a tough year, we in this room are also the people in our industry who understand that it is still important to work on the strategic things that will protect and advance our industry for the years to come.

So, let’s talk about strategy and look back at the last two years of IAPD. In early 2023, we surveyed leaders across our member companies asking them how IAPD could help their companies and what IAPD should focus on.

The three areas that we heard the most, by far, were:

- Attracting, Recruiting and Retaining Talent (Workforce Development)

- Government Relations

- Sustainability

Driving Value Forward:

A Shared Commitment

Incoming IAPD President 2025 – 2026

t is a privilege to serve as the incoming president of IAPD — The Performance Plastics Association. I want to thank Peter DelGado for his leadership and dedication as president, his steady guidance over the past two years has strongly positioned IAPD for the future. Now, it’s my goal to carry that momentum and continue strengthening the value IAPD delivers to every member.

My focus as your president this coming year is driving value forward, ensuring that IAPD continues to be relevant and resilient in a changing world.

Over my 40 years with PLASKOLITE, I’ve often heard the same question that many of you may ask: What’s the value of membership? Why should my company do more than attend the convention or an occasional event?

Showcase

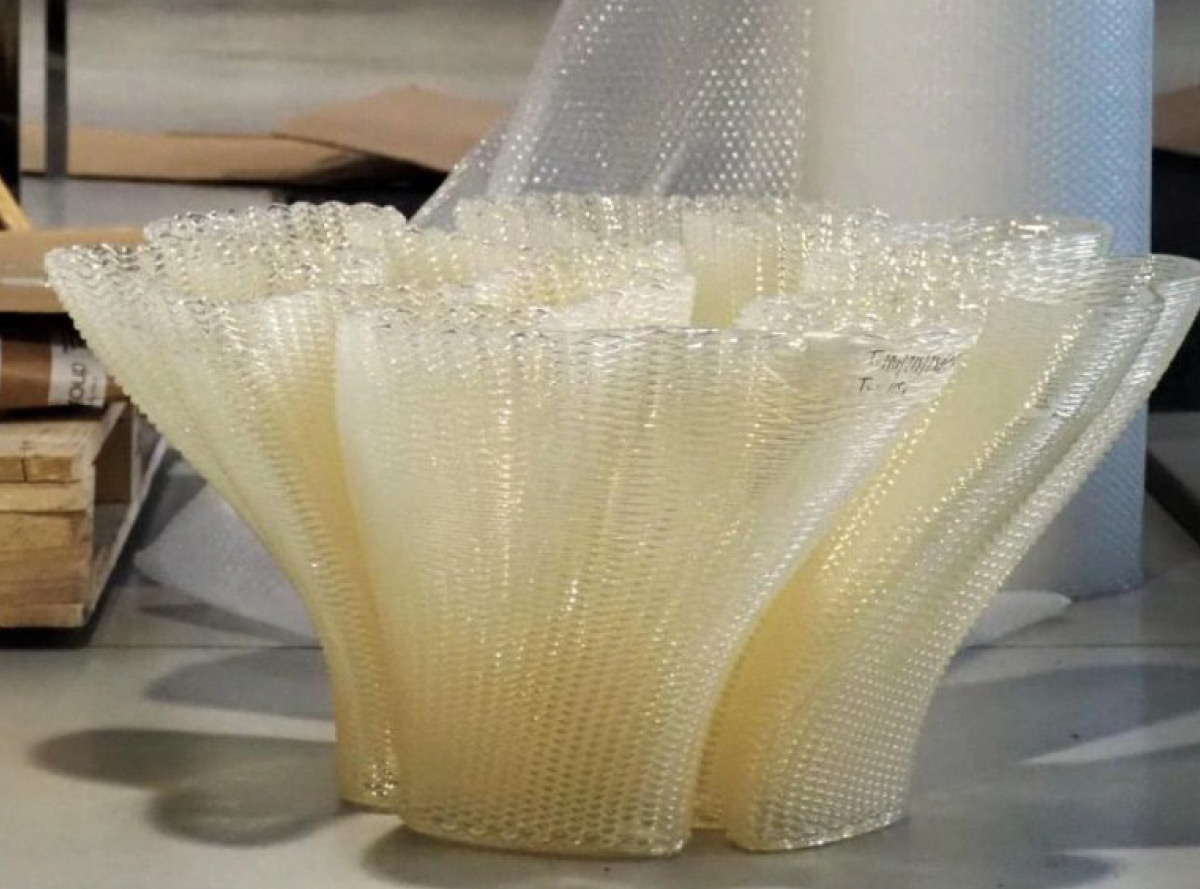

What makes Nomura particularly compelling is the material choice: with more than 60% biobased content derived from castor beans, Rilsan Clear offers a significantly lower-carbon-footprint alternative to traditional fossil-based plastics, aligning durability with sustainability. The project uses large-format additive manufacturing (not filament) and recycles waste plastic (e.g., from used eyewear frames), regrinding it into high-quality granules for printing.

News

Produced through an energy-efficient manufacturing process, the foams feature a fine, homogeneous cell structure with density and material properties that can be tailored to customer requirements. Depending on the base polymer, the materials can withstand temperatures up to 300°C and exhibit strong resistance to oils, greases, cleaning agents and solvents. These properties make them suitable for lightweight structural components, impact-resistant parts and applications requiring long-term durability in chemically aggressive environments.

Curbell Plastics, Inc. Employees Give Back across the Nation

urbell Plastics, Inc. is demonstrating that community impact extends far beyond the workplace. Through the company-wide Curbell in the Community initiative, employees across the United States are dedicating their time, talents and creativity to support local charities, families and neighborhoods. From fundraising to hands-on volunteering, team members are making a meaningful difference where they live and work.

In Western New York, Senior Outside Sales Representative Jeffrey Wangler organized Curbell’s involvement in the first annual Christ the King School Golf Tournament, helping raise funds for campus improvements that will enhance safety and comfort for students and staff. In Phoenix, Senior Inside Sales Representative Kevin Sheely combined his passion for music and service by hosting a benefit concert supporting the Agua Fria Food & Clothing Bank, raising US$535 and collecting 29 cases of bottled water for families facing extreme heat.

Sustainability in Action

Celebrating the 2025 IAPD Environmental Excellence and Impact Award Winners

ach year, IAPD honors member companies that demonstrate outstanding commitment to environmental responsibility through the Environmental Excellence Awards and the Environmental Impact Award. These recognitions highlight the innovative recycling programs, resource-conservation efforts and creative problem-solving taking place across the performance plastics supply chain. From companywide initiatives that reduce waste and improve efficiency to project-specific achievements that divert challenging materials from landfills, this year’s winners exemplify the leadership and environmental stewardship that continue to move our industry forward.

Curbell Plastics, Inc. earned Gold-level recognition for its comprehensive, companywide sustainability program. The company diverts 51–90% of its plastic scrap from landfills through partnerships that return material for reuse, convert scrap into reprocessed products and support zero-landfill operations at multiple locations.

In the midst of AI-driven demand explosion, data centers turn to thermoplastics

semiconductors

by Dan Mesler, PLASKOLITE

he data center industry is in the throes of an AI-fueled transformation, with data center capacity projected to grow from 60 gigawatts (GW) today to as much as 298 GW by 2030, with about 70% of that dedicated to AI. That means we can expect a massive influx of new data centers, most of which will feature new approaches to design and infrastructure to support AI workloads. As a result, the industry is expected to make nearly US$7 trillion worth of capital expenditures over that time, with $5.2 trillion of that investment dedicated to AI.

A growing chunk of that investment is going to thermoplastics, which are becoming increasingly common in chip and facility design as AI changes the power and thermal profiles of the data center. Thermoplastics such as polycarbonate, PVC and CPVC are replacing perforated metal and other materials because they perform as well or better than legacy materials and have other advantages. More specifically, materials like multiwall PC, monolithic PC, acrylic, HDPE and PP are also designed for places where metal can’t be used and corrosion or flame resistance is needed. Applications where these thermoplastics are best suited include:

- Airflow and containment systems

- Door and panel glazing

Thermoplastic Material Selection in a Semiconductor Manufacturing Plant

semiconductors

by Dr. Tim Biggs, Roechling Industrial Gastonia

aterial selection is a critical and complex challenge in semiconductor manufacturing, driven by the need for ultra-high purity, extreme precision, and resistance to harsh processing environments. While the primary chip material is typically silicon (or other III-V materials like Gallium Arsenide), specialized high-performance plastics are essential for the manufacturing equipment and cleanroom infrastructure.

The technical selection criteria for these support materials are stringent, focusing on factors like:

- Contamination Risk: Ultra-low outgassing and leachables to prevent micro-contamination of the wafer.

- Chemical Resistance: Impermeability to corrosive acids, solvents, and plasma used in wet and dry etching.

- Thermal and Dimensional Stability: Ability to maintain shape and performance under high-temperature processes and precision machining requirements.

The Materials Behind the Wafer:

Engineering for Performance and regulatory alignment

semiconductors

by Will Slade, Ensinger

Engineered Thermoplastics for Semiconductor Cleanrooms:

Meeting Cleanliness and Performance demands

Semiconductors

by Ian Donohue, SEKISUI KYDEX, LLC

n semiconductor manufacturing, the pursuit of ever smaller and more powerful devices has made controlling contamination a key priority. Cleanrooms form the backbone of this effort, and the materials chosen for their construction and outfitting are crucial for maintaining the necessary cleanliness. The standards for semiconductor cleanrooms are strict. ISO 14644 classifications, which specify the maximum allowed particle counts, are just the starting point. Material manufacturers must ensure their products do not shed particles, outgas, or generate static. They must also endure repeated cleaning with aggressive agents and disinfectants, such as PDI disinfectant wipes, while maintaining their structural integrity and appearance. These requirements apply to every surface and component, from large wall panels to the smallest tool covers.

When the right thermoplastic is used, it can offer a combination of properties that make them ideal for semiconductor cleanrooms:

- Non-shedding surfaces: Unlike painted metals or composites, thermoplastics provide smooth, sealed surfaces that resist particle generation.

- Chemical resistance: Thermoplastics can withstand aggressive cleaning agents and process chemicals, ensuring longevity in harsh environments.

High-performance Fluoropolymers for Semiconductor Processing Equipment

Semiconductors

he plastic materials used in semiconductor fabs have to meet stringent requirements for purity, flammability and chemical resistance. Fluoropolymer materials excel in these areas and these plastics are frequently specified for semiconductor IC chip manufacturing applications. The purpose of this article is to provide an overview of the fluoropolymers used in semiconductor processing and also describe some of the common applications for fluoropolymers in the semiconductor industry.

Semiconductor equipment designers have a wide range of fluoropolymers to choose from including PTFE, FEP, PFA, PVDF, ETFE and ECTFE. These plastics can be divided into two categories: fully fluorinated fluoropolymers (PTFE, FEP and PFA) and partially fluorinated fluoropolymers (PVDF, ETFE and ECTFE). As shown in the graph below, fully fluorinated polymers have lower flexural modulus (stiffness) than partially fluorinated polymers, which means that PTFE, FEP and PFA are softer and easier to bend than PVDF, ETFE and ECTFE. Because of this, fully fluorinated polymers are often used for applications such as flexible tubing where the ability to be bent into position for assembly is required.

APD – The Performance Plastics Association, concluded its 69th IAPD Annual Convention + connecX on October 2, 2025, at the Marriott Marquis Chicago in Chicago, IL, USA. This event welcomed delegates from across the world for a week of critical industry conversations about workforce retention, upcoming federal legislation/regulations and economic forecasting; as well as supplier meetings and ample professional networking opportunities.

The General Sessions featured insightful keynote presentations exploring artificial intelligence with Sam Richter and channel conflict with Ian Heller.

The IAPD connecX showcase was held on Wednesday. The new Technical Showcase sessions added additional educational opportunities for trade show attendees and strong engagement was seen across the show floor.

Convention delegates enjoyed a taste of Chicago throughout the week, starting with classic deep dish pizza and hot dogs served at the Welcome Reception and wrapping up the week with scenic views of the skyline at the VU Rooftop.

Save the date: The 70th IAPD Annual Convention + connecX will be held September 28 – October 1, 2026 in Atlanta, GA, USA.

From left: IAPD President Peter DelGado, 2025 Paul Davis Award of Merit recipient Karen Debard and IAPD Vice President Jim Richards.

Paul Davis Award of Merit

connecX TRADE SHOW

at Vu Rooftop

People &

Places

-

Tony Severkovski

Richard Andrus

Mike Neisen

Tommy KedroutekProfessional Plastics, Inc. is pleased to announce the promotion of four long-standing employees. Tony Severkovski was appointed national sales director – distribution at Professional Plastics. Taking on the role, he will strive to align company values, provide market and product strategies, measure distribution performance and manage inventory. With more than 20 years of experience, he is eager to bring his deep knowledge and expertise to the role. “I look forward to my new position and continuing my sales leadership and guidance, while increasing corporate sales and revenue,” said Severkovski.

Tony Severkovski was appointed national sales director – distribution at Professional Plastics. Taking on the role, he will strive to align company values, provide market and product strategies, measure distribution performance and manage inventory. With more than 20 years of experience, he is eager to bring his deep knowledge and expertise to the role. “I look forward to my new position and continuing my sales leadership and guidance, while increasing corporate sales and revenue,” said Severkovski. Richard Andrus was promoted to business manager of the company’s Portland, OR location. Andrus will oversee daily branch operations and ensure efficient management of inventory, sales, and customer relations. He will also work to develop strategies that meet sales targets while maintaining strong relationships with suppliers. Andrus brings 25 years of experience to his new management role, most recently as a top sales performer at the company. He looks forward to contributing to the company’s successful future in his new capacity.

Richard Andrus was promoted to business manager of the company’s Portland, OR location. Andrus will oversee daily branch operations and ensure efficient management of inventory, sales, and customer relations. He will also work to develop strategies that meet sales targets while maintaining strong relationships with suppliers. Andrus brings 25 years of experience to his new management role, most recently as a top sales performer at the company. He looks forward to contributing to the company’s successful future in his new capacity. -

Matt Gross

JD Capel

Jeff Norris

Chandler Benson

Frank Marcial

Bailey Mrozek Professional Plastics, Inc. also expanded its corporate and sales teams by welcoming eight new employees.Matt Gross joined Professional Plastics as the managing director of engineering material sales & fabricated parts. Based in Jacksonville, FL, he brings 18 years of experience and will focus on growing the company’s national footprint by connecting key accounts across multiple regions and aligning branches through a coordinated market approach. “I’m excited to join Professional Plastics and help bring a more unified, strategic approach to the way we serve customers across North America,” said Gross.

Professional Plastics, Inc. also expanded its corporate and sales teams by welcoming eight new employees.Matt Gross joined Professional Plastics as the managing director of engineering material sales & fabricated parts. Based in Jacksonville, FL, he brings 18 years of experience and will focus on growing the company’s national footprint by connecting key accounts across multiple regions and aligning branches through a coordinated market approach. “I’m excited to join Professional Plastics and help bring a more unified, strategic approach to the way we serve customers across North America,” said Gross.

REP BUSINESS

Exchange

Fabrication

SERVICES SHOWCASE

Fabrication Services Showcase contains paid listings of companies with fabrication services, products and machinery that cater to the performance plastics distribution industry. IAPD does not endorse nor make recommendations in regard to the companies supplying their services. For details and pricing information to include your company in this Fabrication Services Showcase, contact Jessica Bokath, IAPD’s director of sales, at (913) 345-1005 or email jbokath@iapd.org.

CNC Equipment

Sawing, trimming, drilling, polishing, measuring or 3D processing — no matter what techniques are involved, Stiles has the CNC technology to get it done. Their machining solutions can be custom-configured to your specific needs. From productivity and high precision, to energy and material savings, Stiles provides proven CNC options for plastics processing. For more information, contact info@stilesmachinery.com or visit www.stilesmachinery.com.

Vortex Tool Company, Inc. designs and manufactures a wide variety of standard and custom high-performance router and insert cutting tools for the woodworking and plastics industries, and provides retipping and sharpening services for all makes and models. www.vortextool.com, phone (800) 355-7708.

special advertising supplement

Annual

Corporate Profiles

IAPD is proud to present its annual look at innovative companies in the performance plastics industry. Enjoy learning more about the wide range of materials, equipment and services available from these advertisers.

Georgetown, SC, USA

The Plastics Experts

ince 1988, Georgetown, SC–based AGRU America, Inc. has created innovative engineering plastics solutions for a safer and more sustainable future. AGRU America is part of AGRU Kunststofftechnik GmbH, an Austrian family-owned enterprise in business since 1948. AGRU maintains production facilities in Austria, the United States and China. AGRU solutions, including state-of-the-art products such as AGRU geosynthetics, concrete protective liners, pipes and fittings and semi-finished products, are sold in over 100 countries on six continents from over 150 distribution sites.

AGRU America comprises five U.S. manufacturing facilities, four in South Carolina and one in Fernley, NV. These facilities produce or distribute products under three engineering plastics categories: geosynthetics, pipes and fittings, and semi-finished products. AGRU solutions combine various AGRU products and services to offer engineers avenues to tackle complex application challenges, including waste management, water/wastewater, mining, energy, industrial and construction. AGRU promotes the U.N. Sustainable Development Goals by creating solutions supporting access to clean water and sanitation, affordable and clean energy, infrastructure and communities.

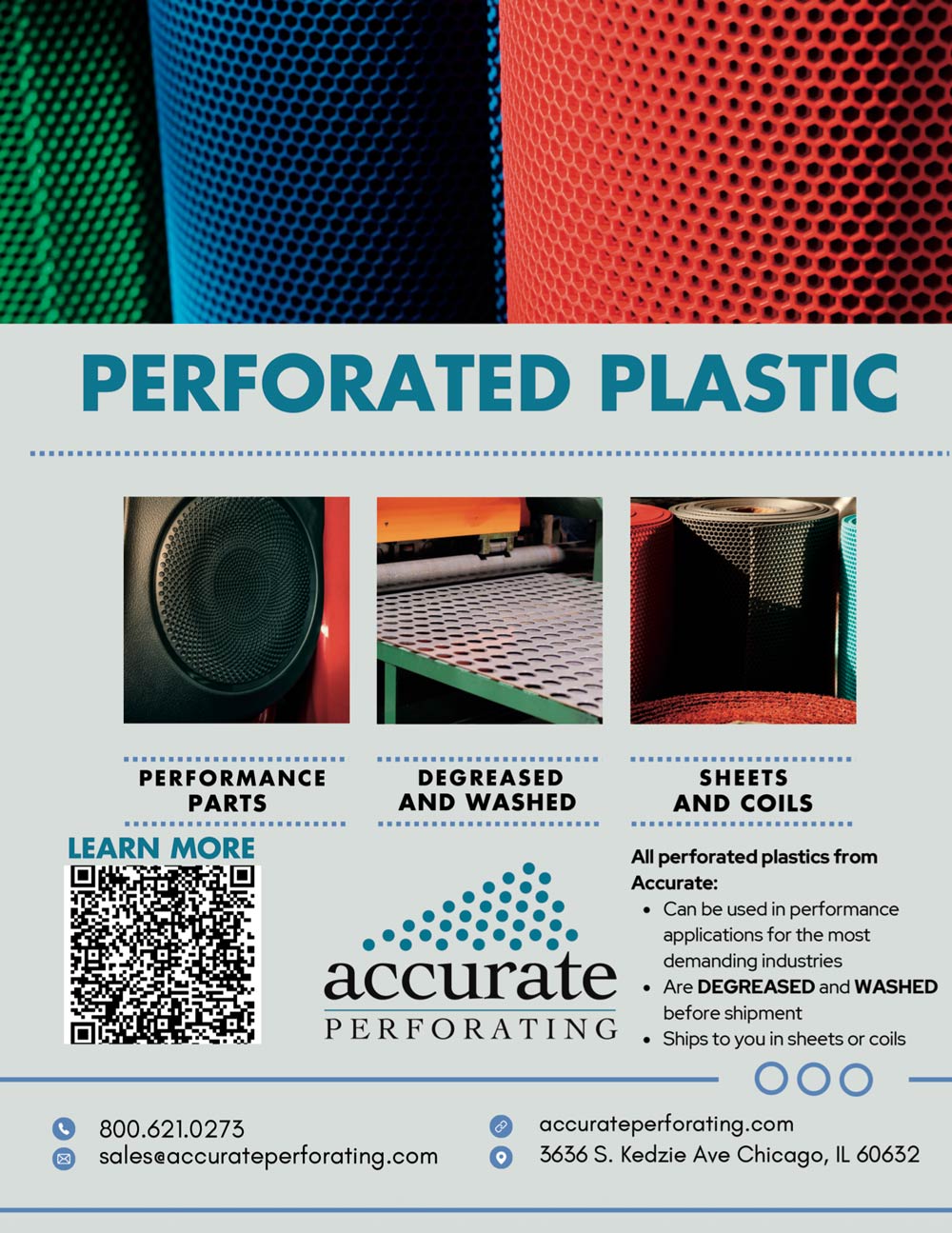

Chicago, IL, USA

Precision, Partnership and performance

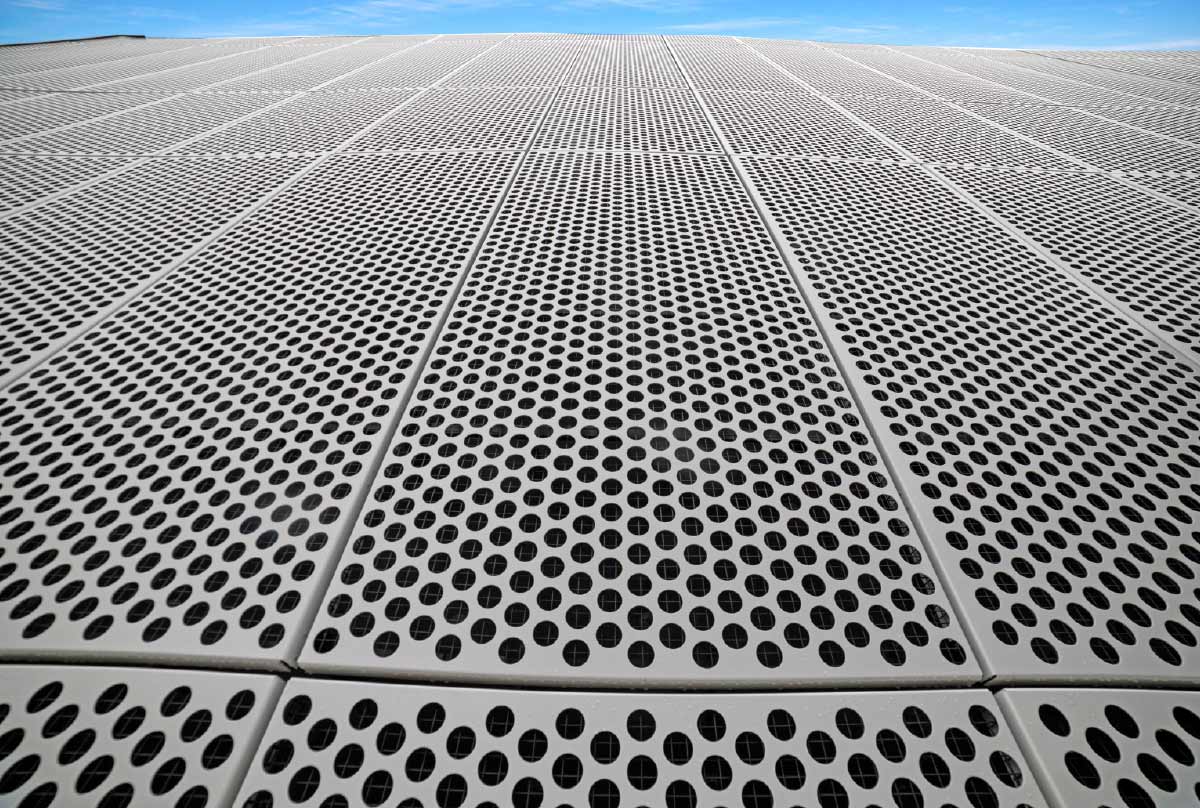

or more than 80 years, Accurate Perforating has been at the forefront of innovation in perforated materials — from metal to plastic and everything in between. Founded in Chicago in 1942, the company has grown into a national manufacturing leader with a reputation for technical expertise, responsive service and true start-to-finish capability.

As part of the Accurate Family of Companies, which also includes Accurate Metal Fabricating and SelectSpace Partitions, the organization operates under a single mission: to help customers turn complex ideas into finished products with precision, consistency and speed. Today, Accurate’s work can be found in everything from architectural façades and data-center enclosures to filtration systems, energy infrastructure and performance plastics.

ecognized as a worldwide leader in plastics processing technology and application development, Ensinger has the ability to combine the optimum materials solution with the most suitable manufacturing method, and thus provides the industry with the most innovative and cost-effective engineering solutions available today. Ensinger designs and manufactures semi-finished and finished products tailored exactly to the customer’s individual requirements. Your projects can benefit from Ensinger’s vast knowledge base and many years of experience in finding the best solutions for problems involving engineering thermoplastics materials.

Ensinger offers a broader array of engineering materials than any other plastics processor. From general industrial materials such as polypropylene, polyethylene, acetal and nylon to high performance resins such as TECAPEEK® polyetheretherketone and TECATRON® polyphenylene sulfide, Ensinger has the ability to provide shapes and parts for even the most difficult and challenging applications and environments.

COMMITTED TO QUALITY AND CONTINUOUS IMPROVEMENTS

ince their inception more than 50 years ago, Hudson Extrusions, Inc. has been dedicated to a singular goal: “Total Customer Satisfaction.” They strive to exceed their customers’ expectations through outstanding customer service, quick turnaround times and producing extruded plastic tubing and profiles of exceptional quality.

Having been family-owned and -operated since 1956, they value the personal service that has become scarce in today’s technologically advanced environment. Their knowledgeable sales staff has a combined 40+ years of experience in the plastics industry and are ready to help with any questions or inquiries you may have.

Our Innovation. Your Imagination.®

ing Plastic Corporation is a leading manufacturer of quality polymer sheets, slabs and massive shapes — including several products pioneered by the company. Its polymers are made in the United States and sold worldwide through a network of top plastics distributors to customers who fabricate products for the marine industry (King StarBoard® brand), signage, food service, healthcare, architectural, industrial and other markets. King Plastic manufactures more than 20 products including:

- King StarBoard® — The original marine-grade polymer sheet

- King StarBoard® AS — The anti-skid marine-grade polymer sheet

- King StarBoard® XL — The lightweight marine-grade cellular sheet

Innovation

Innovation Quality

Quality Worldwide Distribution

Worldwide Distribution

Palram Americas, Inc.

Kutztown, PA, USA

POLYCARBONATE & PVC POWERHOUSE

ith time-tested resources, proprietary technologies and a rich history of expertise, Palram has become a trusted partner to markets spanning industrial; construction and architecture; safety and security; sign and display; transportation; and outdoor living.

From our seasoned sales reps and knowledgeable and responsive customer service team to timely shipping, and broad breadth of offering, Palram is committed to providing world-class service.

Experience the benefits of a nimble, single source supplier of high-quality polycarbonate and PVC.

PBY Plastics, Inc.

Ontario, CA, USA

BY Plastics is recognized as a leading compression molding manufacturer specializing in high-performance industrial polymers. The company partners with top-tier resin suppliers to deliver precision-engineered components for demanding applications. Its product range includes sheets, rods, tubes, discs, rings and custom molded parts.

PBY’s material portfolio is extensive, organized into two primary series:

- PB10000 — Non-melt processible fluoropolymer including PTFE (standard, modified and porous) virgin or filled with carbon, carbon graphite, bronze, stainless steel, aromatic polyester, Ekonol® and polyimide.

- PB20000 — Melt-processible fluoropolymers, including PFA, FEP, PVDF, PCTFE, ETFE and ECA 2000.

Additional offerings include PEEK, UHMWPE and PEI for specialized applications.

olymer Industries is nearing 50 years of manufacturing performance plastics and the quality standards that built the foundation of the company are still in place today. As we have worked hard to accommodate the growing needs of our customers, the company has grown and its product portfolio expanded.

Today, Polymer Industries is proud to offer one of the largest performance plastics product offerings from a single manufacturer. Our polyolefin product line includes Densetec® high density polyethylene (HDPE), polypropylene (PP), high molecular weight polyethylene (HMW), low density polyethylene (LOPE) and Polyslick® ultra high molecular weight polyethylene (UHMW PE).

The Rowmark Group | TRG

Findlay, OH, USA

or more than 40 years, The Rowmark Group (TRG) has been the world’s leading manufacturer of engravable sheet plastic designed for laser and rotary engraving for the awards, personalization and the signage markets, and carries a complete line of products for digital and UV-LED printing. Known for its product innovation, Rowmark is the exclusive manufacturer of products such as LaserGlow®, a glow-in-the-dark signage material designed to meet and exceed photoluminescent standards set by many cities and municipalities, and EcoMark, the industry’s first laser engravable sheet material made from 100% post-consumer plastic.

In addition to our complete line of engravable sheet materials, TRG has custom extrusion and surface decorating capabilities for thermoforming and other applications. TRG offers surface decorating with custom thermoformable films made to specification and advanced robotic hydrographic application to a range of materials.

Rajkot, Gujarat, India

ADVANCING PERFORMANCE PLASTICS THROUGH INNOVATION, SUSTAINABILITY AND GLOBAL REACH

ilara Polyplast Pvt. Ltd. is widely recognized as one of the most forward-thinking manufacturers in the performance plastics industry, delivering high-quality sheet products that meet the evolving needs of distributors, fabricators and OEMs around the world. Built on a foundation of innovation, reliability and customer-centric values, Tilara has grown from a regional manufacturer into a global supplier trusted across construction, fabrication, printing, signage, industrial and architectural applications. The company’s continued expansion reflects its unwavering commitment to engineering excellence and its deliberate investment in modern manufacturing technologies that elevate industry standards.

egener Welding, LLC is an international supplier of high-quality welding, processing and testing equipment for thermoplastic materials. Their mission is not only to offer a wide range of quality products, but to ensure that our customers have access to customized solutions, expert advice, training programs and reliable service and support. A dedicated team of knowledgeable personnel are available to aid in defining the proper equipment for the job, as well as finding solutions to any welding problems their customers may have.

In 2006, Wegener Welding, LLC emerged as a new entity out of what was formerly known to the industry as Wegener North America, Inc., which had serviced the market with their range of sheet-related thermoplastic welding and fabrication products since the early 1980’s. The product lines of our partners Wegener International GmbH, Hürner Schweisstechnik GmbH, and Buckleys (UVRAL) Ltd. form a comprehensive source of plastic welding and testing equipment unique to the industry.

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Accurate Perforating • (800) 621-0273 • www.accurateperforating.com

Ensinger • (800) 243–3221 • www.ensingerplastics.com

Hudson Extrusions, Inc. • (800) 837–6015 • www.hudsonextrusions.com

King Plastic Corporation • (800) 837–6015 • www.kingplastic.com

PBY Plastics, Inc. • (909) 930-6700 • www.pbyplastics.com

Palram Americas • (800) 999–9459 • www.palramamericas.com

Polymer Industries • (256) 657-5197 • www.polymerindustries.com

Rowmark LLC • (800) 243–3339 • www.rowmark.com

Tilara Polyplast Pvt. Ltd. • (310) 505-0950 • www.tilarapolyplast.com

Wegener Welding, LLC • (800) 647–3061 • www.wegenerwelding.com

BoardofDirectors

Brent Brelsford • Piedmont Plastics, Inc. • Charlotte, NC, USA

Chad Cecil • Meyer Plastics, Inc. • Indianapolis, IN, USA

Katie Clapp • A&C Plastics, Inc.• Houston, Texas, USA

Chris Corona, Executive Committee • CartierWilson LLC • Solon, Ohio, USA

Bryan Davis • Ensinger • Washington, Pennsylvania, USA

Peter DelGado, Immediate Past President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Stephen Garmon, Executive Committee • Primex Corporation • Atlanta, GA, USA

Eric Giesen • ZL Engineering Plastics, Inc. • Lenexa, KS, USA

Hayden Hess, Executive Committee • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke, Executive Committee • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Advanced Materials • Sacramento, California, USA

Jim Richards, President • PLASKOLITE • Columbus, Ohio, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

John Shepherd • Alro Plastics • Jackson, MI, USA

Alicia Spence • SIMONA AMERICA Group • Atlanta, GA, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

6734 West 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE, CEO

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Advertising Sales

Jessica Bokath

jbokath@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Keith Hechtel • Curbell Plastics, Inc. • Orchard Park, New York, USA.

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Publishing

Headquarters

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE, CEO

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Advertising Sales

Jessica Bokath

jbokath@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Editorial Committee

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Keith Hechtel • Curbell Plastics, Inc. • Orchard Park, New York, USA.

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA