of

“Weather Machine” Teaching Tool

Performance Plastics

Cover design by Mackenzie Diekmann, IAPD Design and Multimedia Manager

IAPD SOURCE GUIDE

- All IAPD Members Geographical Listings

- Plastics Material and Shapes Guide

- Resin & Semi-Finished Plastics Manufacturers

- Equipment & Services Providers

- Plastics Trade Names Directory

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

United We Stand, Divided We Fall

This article is excerpted from Deborah Ragsdale’s president’s speech, delivered at the 66th Annual IAPD Convention in Tampa, FL, USA on September 14, 2022.

by Deborah Ragsdale, Polymer Industries

IAPD President

heard a story about a successful business owner who was worried about the future of his company. He has three grown sons who are constantly at each other’s throats. He’d like to hand the business over to them, but he’s worried about them destroying it. He worked so hard to build this empire and he had to find a way for his children to work together to ensure a successful future.

One day, he called them to him. He held a bundle of sticks in his hands. He handed the bundle to his oldest child and told him to break it. The first son grabbed the bundle and tried breaking it with his knee, but it wouldn’t even bend. He handed it to his sibling to try and break. The second child tried many ways to break the bundle: he tried stepping on it, throwing it on the ground and tried to break it with his hands. The third son said, “I am stronger than both of you. Let me try.” The bundle of sticks was passed to the third son, who tried to break the sticks with all his might.

The three children brought the bundle of sticks back to the father and said, “We couldn’t break it. Why did you ask us to do this?”

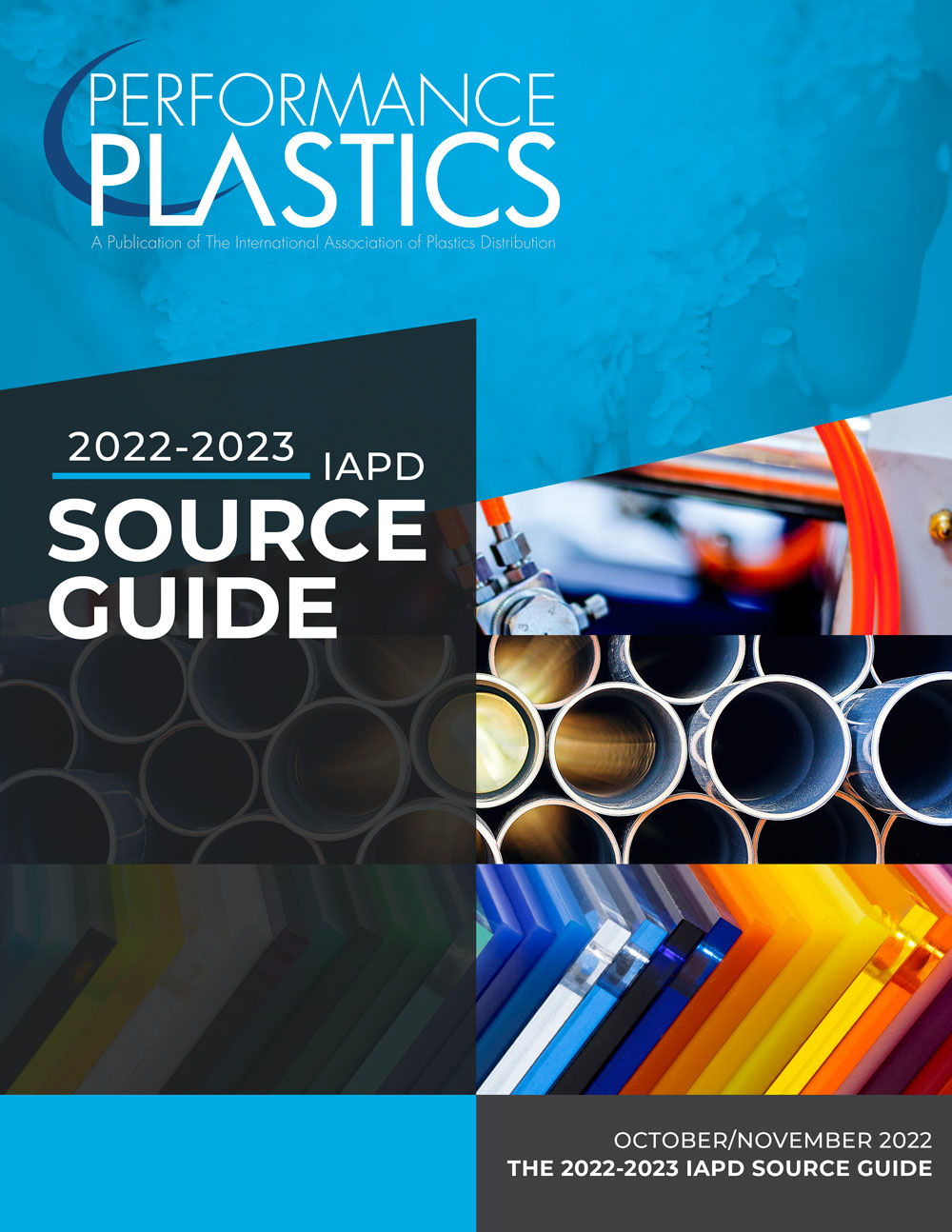

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

PTFE

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

Contact Altaflo at 973-300-3344 or sales@altaflo.com.

IAPD CEO

f you’ve been to the IAPD website lately, you might have noticed a new logo in the upper left hand corner. The art is the same, but there is a subtle — yet significant — change to the grey type. IAPD Vice President Peter DelGado of Curbell Plastics, Inc. unveiled the logo with the tagline on Wednesday, September 14, 2022, during his speech at the opening general session of the 66th Annual IAPD Convention and connecX in Tampa, FL, USA.

“The IAPD Board of Directors and Executive Committee had numerous conversations about the association name and how to integrate ‘performance plastics’ into the branding. They ultimately decided that they did not want to change the association name, as it is still an accurate representation of what the organization stands for: a trade association composed of companies from around the world that believe in distribution as the way to market for performance plastics,” said DelGado. “However, they still wanted to integrate the word ‘performance.’ Thus, the concept of adding a tagline was proposed, and IAPD leadership approved “the performance plastics association.”

Flat Stock

Sheet Stock

Profile Shapes

Fabrication

3311 Enterprise Road

Fort Wayne, IN 46808

Articles reporting on plastic products are prepared from information furnished by members of the IAPD and non-member magazine advertisers. The information provided is deemed reliable but is not verified. It should not be assumed that the publisher has reviewed or tested any of the products. For more information, contact companies by visiting their websites.

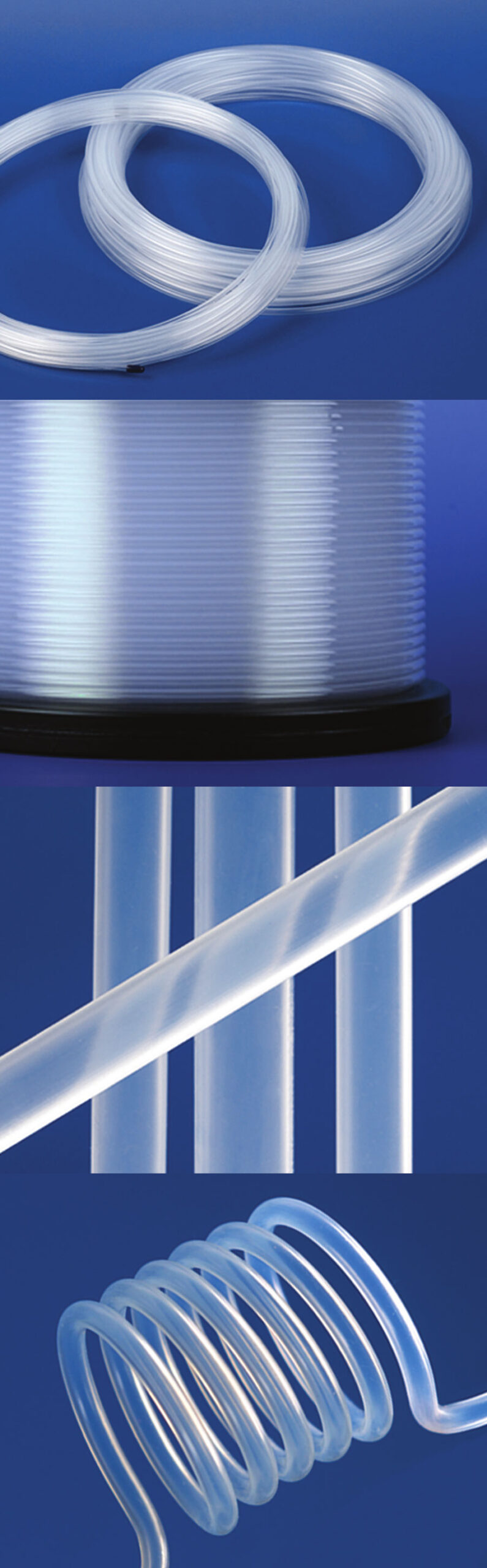

© Algicel

Microalgae produce valuable biomass more efficiently than any land plant. Since these little all-rounders primarily require plenty of even light to do their job, the algae grower Algicel relies on transparent ACRYLITE® tubes.

Microalgae are used in a variety of ways: In dietary supplements, cosmetics, pharmaceutical products and even in energy generation. Researchers are constantly discovering new applications for these miracle plants.

The founders of the Portuguese company Algicel discovered a high concentration of the antioxidant astaxanthin in the microalgae in their native Azores, more precisely on the island of São Miguel. Antioxidants protect not only the skin’s cell structure, but also the whole body against oxidative stress and aging symptoms as well as inflammation.

Since 2007, the company has been researching a way to produce the health-promoting substance astaxanthin from the microalgae growing in their natural environment on the Azores. After all, the climate and pure inland waters of the islands are ideal for this type of microalgae. In the summer of 2019, the company started the industrial cultivation of the Haematococcus pluvialis species of microalgae based on the technology that was developed in house.

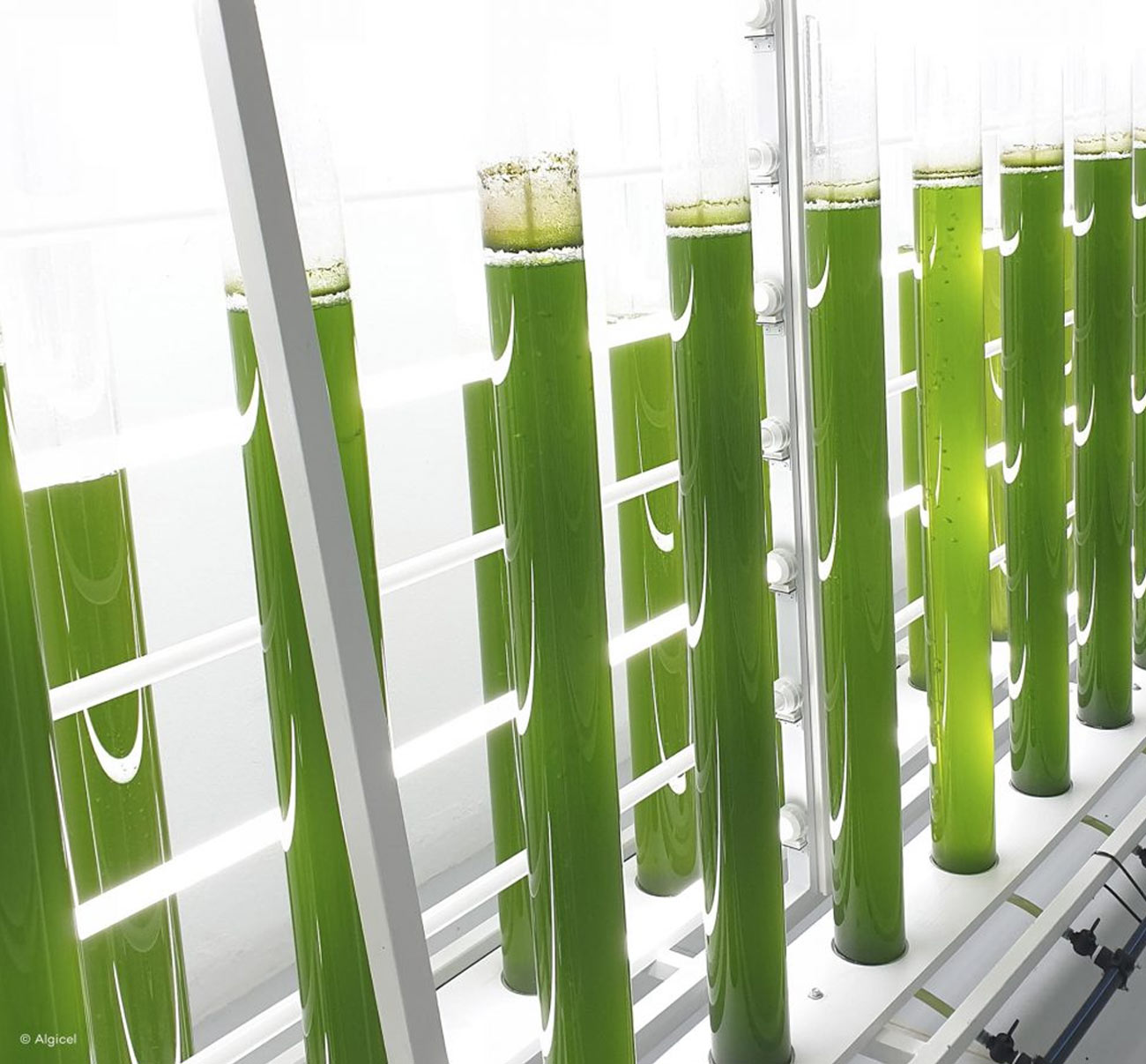

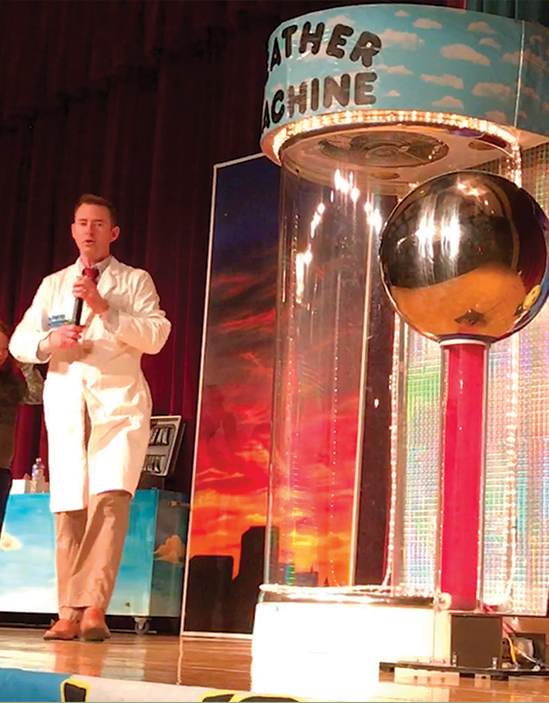

urbell Plastics, Inc. helped Western New York Meteorologist Andy Parker with his Weather Machine, a popular invention and hands-on way to teach students about weather. “The Weather Machine demonstrations are meant to inspire the scientist and inventor in each student,” said Parker, with the purpose of getting the next generation interested in weather and science.

The Weather Machine is built using a large polycarbonate sheet, donated by Curbell Plastics, Inc. It is bent and fit into a frame, creating a clear tube. Inside that tube, weather simulations can be created, such as tornadoes, lightning and snowstorms. Students can reach in and touch a tornado, for example, to feel the air and the vortex, without fear. Parker designed the Weather Machine for children in grades K-6, but it creates a sense of wonder and awe at any age.

Parker began this project by creating smaller scale “desktop” sized weather experiments for single classroom presentations. They were so popular with students and teachers that he started working on a much larger version that could be used to engage hundreds of students in an auditorium.

EnvironmentalCorner

luid system applications and components made with performance plastics are abundant in factories and processing facilities. The right engineered plastic can stand up to hazardous chemicals and can last longer than other materials, contributing to bottom line cost savings. The more we see performance plastics excel in these applications, the more our customers trust the materials. There’s strength in that trust that we must maintain as an industry looked upon by outsiders as susceptible contributors to the growing environmental pollution problem. Together we would be wise to tune in to the growth of recycling of performance plastics industry segment.

There are thermoplastics that are 100 percent inert to corrosive chemicals across the entire pH range. So adaptive are these compounds that companies using polymers and thermoplastics find more efficient ways to mix, store and dissolve heavier concentrations, while removing the waste caused after these desired reactions. Corrosion and contamination can be preempted while significantly reducing cost, weight and maintenance time.

Katie

Clapp

Theresa O’Shei

Joel

Neal

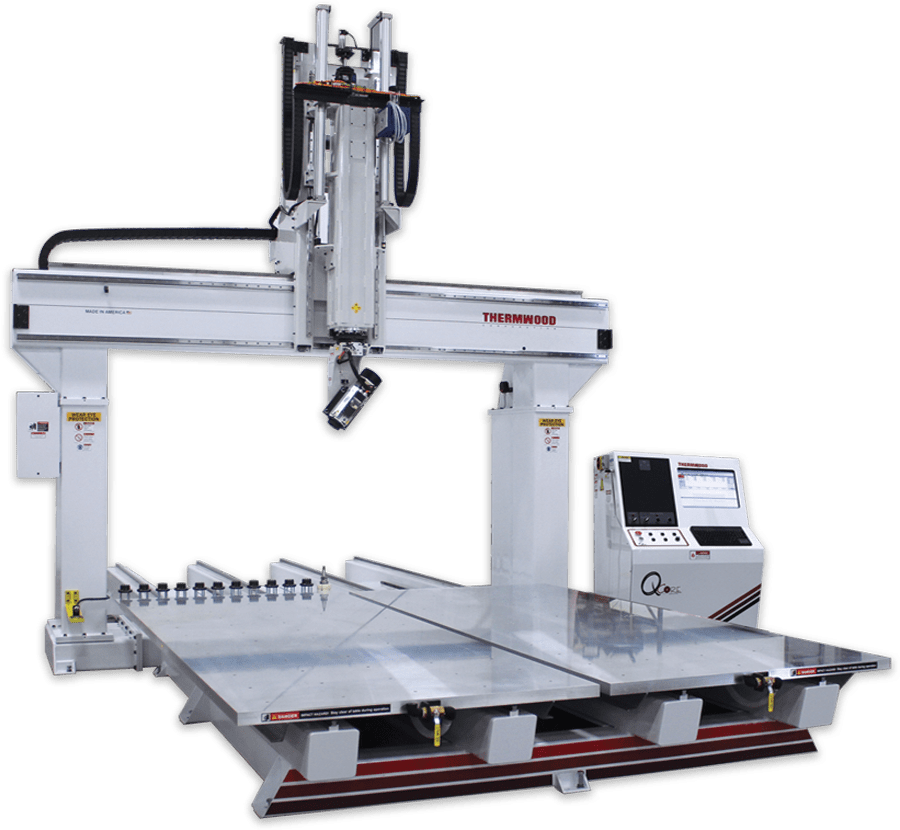

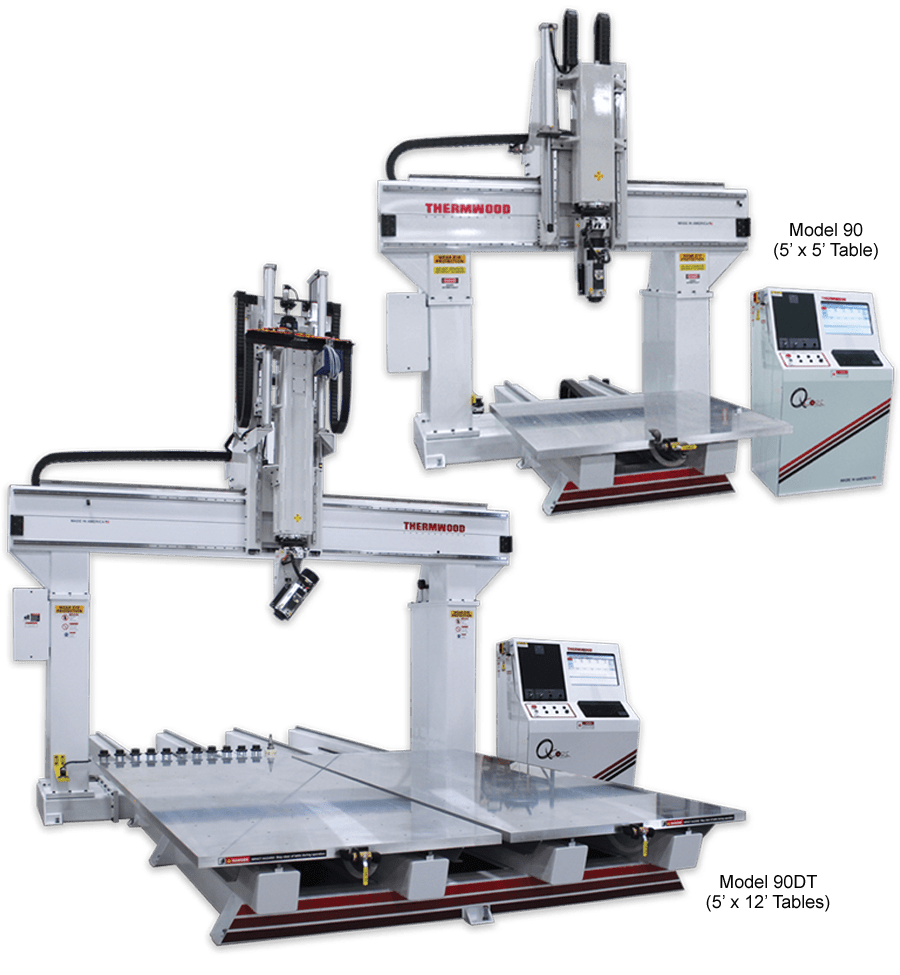

Heavy Duty 5 Axis CNC for

Three-Dimensional Applications

(5’ x 5’ Table)

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

(5’ x 12’ Tables)

800-533-6901

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

800-533-6901

PlasticsWatch