of

Best Practices

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

IAPD President

s you probably know by now, I am a strong believer in developing and building relationships, both business and personal. I’ve experienced first-hand the importance of having relationships that can help get us through tough times. I’ve seen the performance plastics industry rally around those who have lost everything to natural disasters such as hurricanes and flooding. Although we sell plastics, we are all human and we all have good times and hard times. Having a strong network of relationships with people who are there for you during the bad times is, to me, a sign of a successful life.

I’ve learned that nearly all relationships rely on a few key elements. For example, communication is vital. Open and honest communications build trust and deepen your connections. As we all struggle to navigate supply chain disruptions, you know how important it is to keep your channels of communication open with your suppliers and your customers.

Editor’sPerspective

IAPD CEO

rade associations like IAPD serve many functions for members like you. We provide in-person events where learning and networking happens, such as the Annual Convention (and new connecX experience this year) and the recently completed Leadership Development Conference. There are also regional events, such as the golf tournaments, that serve as an opportunity for people who would not typically travel to one of the larger events to network with other IAPD members. The Women in Plastics educational workshops have been a wonderful forum for women (and men!) to learn and network and become connected to the larger community of performance plastics professionals. The IAPD University educational offerings give members free or low-cost ways to train their employees. Many members use the IAPD University training as a standalone way to onboard their new employees, others use it in conjunction with their own proprietary training. The training offerings are designed so that companies can engage in the programming as it works best for them.

Trade associations also monitor outward threats and opportunities for the industry that they serve. For example, IAPD’s government relations program has been instrumental in blocking legislation that would otherwise devastate member companies. Plus, the GR team has ensured that legislators understand the sustainability benefits of performance plastics. Although the anti-plastics attacks are still going on, thanks to the GR program we are monitoring them and standing up to misinformation whenever we see it.

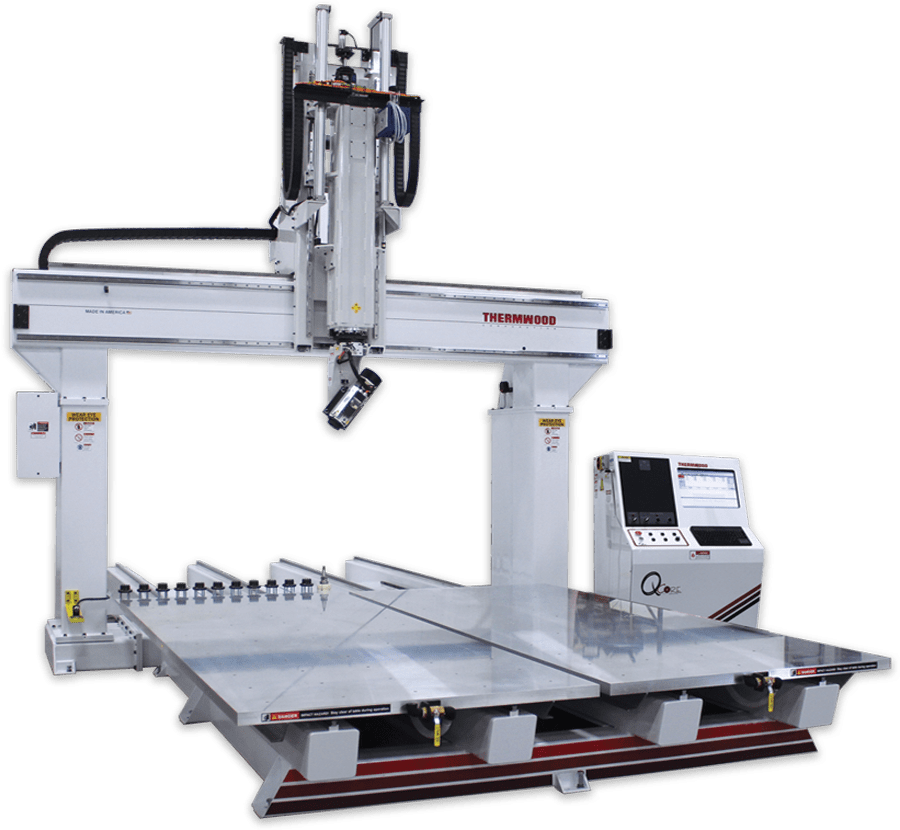

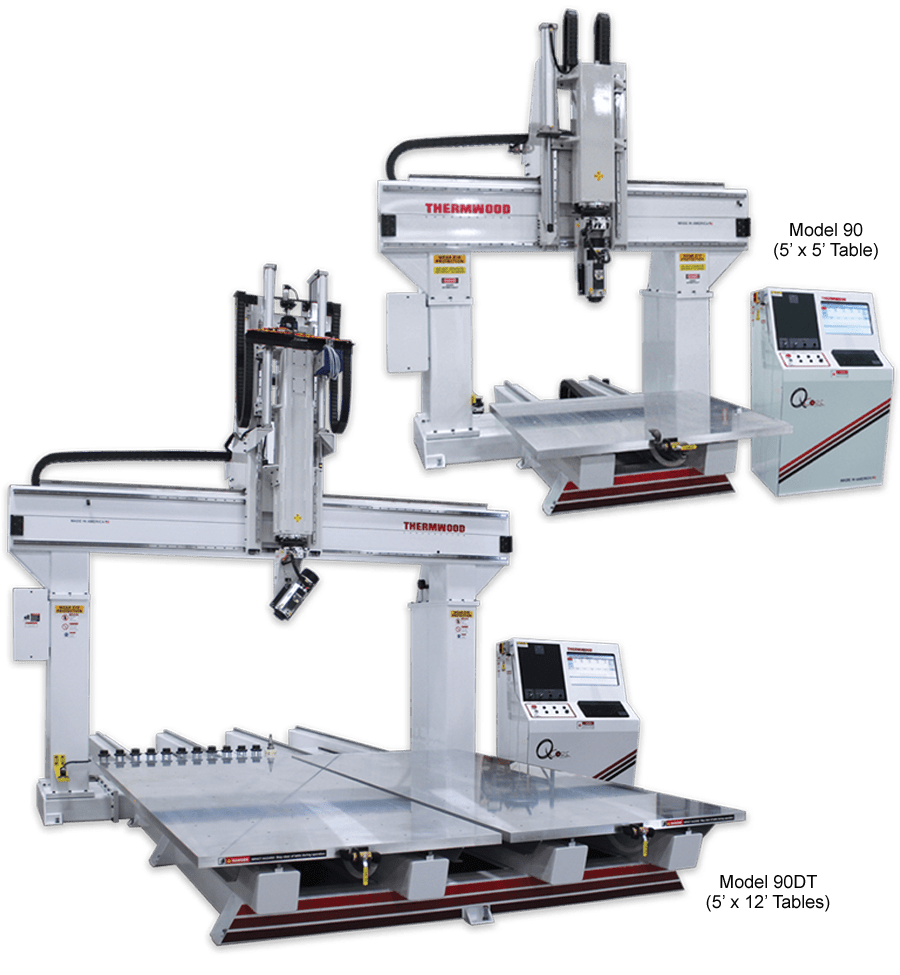

Heavy Duty 5 Axis CNC for

Three-Dimensional Applications

(5’ x 5’ Table)

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

(5’ x 12’ Tables)

800-533-6901

- Plastic Trimming

- Molds

- Patterns

- Non-Ferrous Metal

It is used for production trimming of thermoformed, composite and fiberglass parts as well as being utilized for machine patterns and molds directly from CAD data. This robust system offers a variety of options and features to tackle a multitude of different applications.

800-533-6901

Gears, machine parts, sprockets, star wheels, wear strips and more.

Gears, machine parts, sprockets, star wheels, wear strips and more.

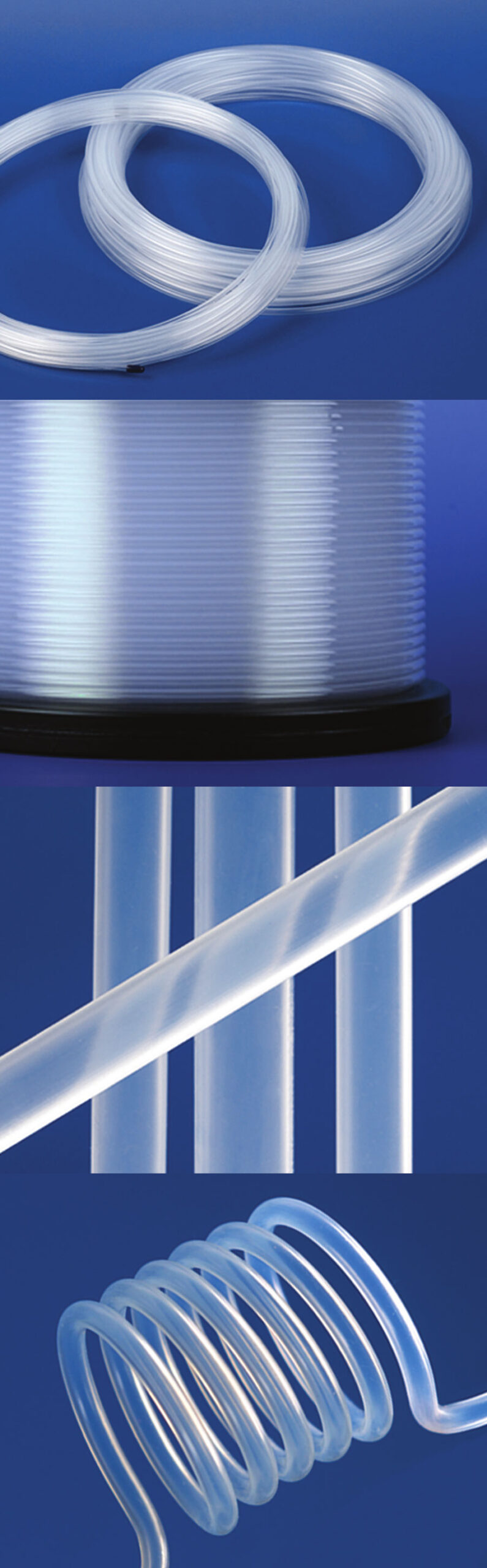

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

Morrow Batteries aims to be the first company in the world to commercialize a battery operating with the LNMO technology as the active cathode material. Due to its special chemistry, LNMO will have a lower cost and carbon footprint compared to batteries with a similar performance. In addition, the optimization of the electrolyte transporting positively charged ions between the cathode and anode terminals should improve the performance and competitiveness of this new generation of batteries.

IPP Columbus, the only set of KIPP schools in Ohio, was founded in 2008 with 50 students in the 5th grade. The KIPP Columbus Learning Campus opened in 2014 on a 125-acre (and growing) state-of-the-art urban landscape educating more than 2,000 students (from infancy to 12th grade) — an increase of 4,000 percent in only six years. With a mission to, together with families and the community, create joyful, academically excellent schools that prepare students with the skills and confidence to pursue the paths they choose — college, career and beyond — KIPP has maintained excellence in its growth and will improve upon that standard, proving what is possible in public education.

Thanks to a generous donation from PLASKOLITE, nearly twice as many central Ohio students will have opportunities for academic excellence and future success. KIPP Columbus announced plans to double its capacity and grow its already substantial community engagement with a bold expansion of its northeast Columbus, OH, USA campus. The expansion is planned for the start of the 2023-2024 school year. It will include the addition of 240,000 square feet and drive academic excellence and increase community partnerships that support KIPP students, their families and the nearby neighborhoods and beyond.

EnvironmentalCorner

pplication and field engineers in the polymer industry are often asked for advice regarding chemical resistance, weathering performance, regulatory compliance, temperature rating, mechanical strength and physical toughness of materials. Lately, as the world adopts a more sustainable mindset, another question has become increasingly popular: “Is the material I am considering readily recyclable?”

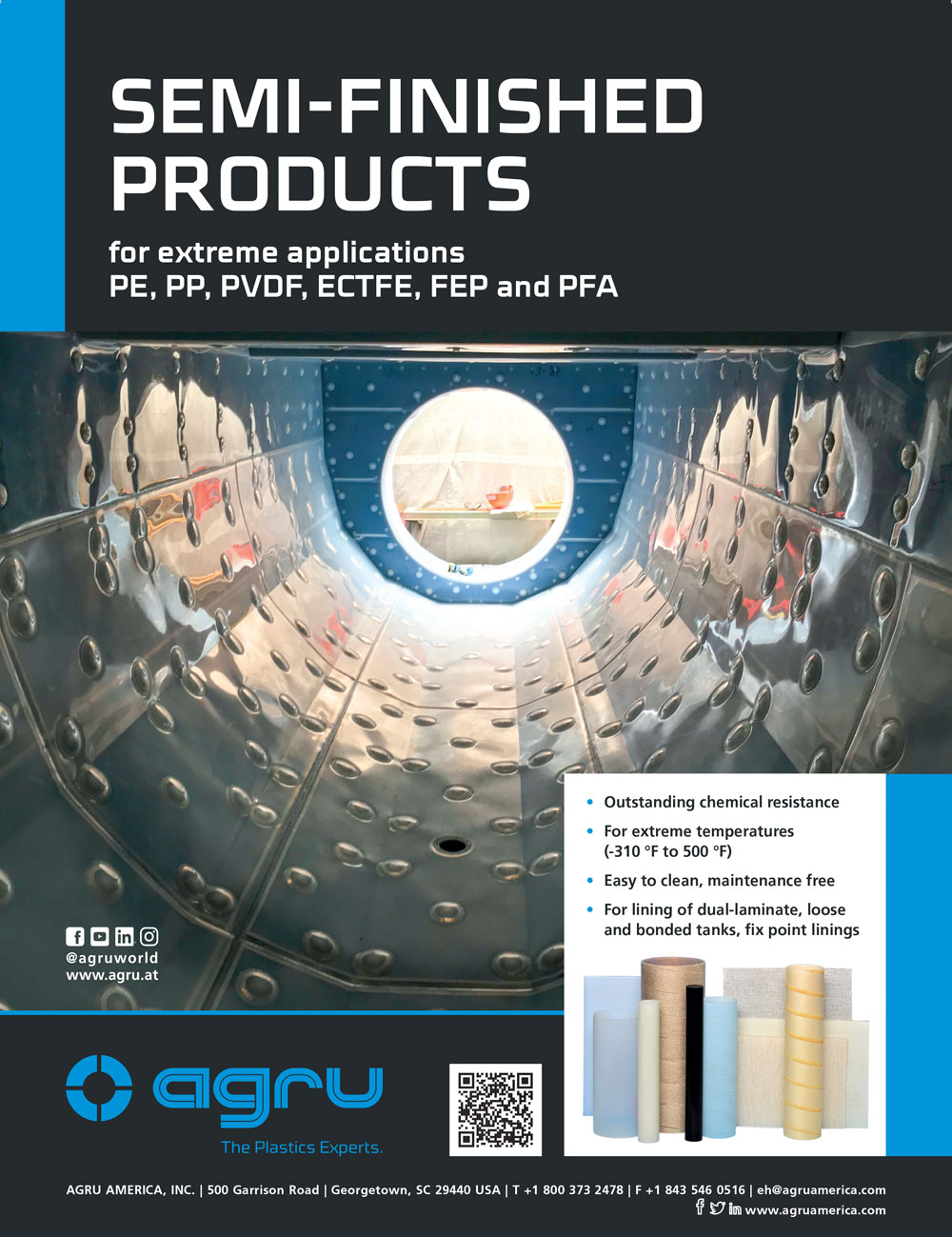

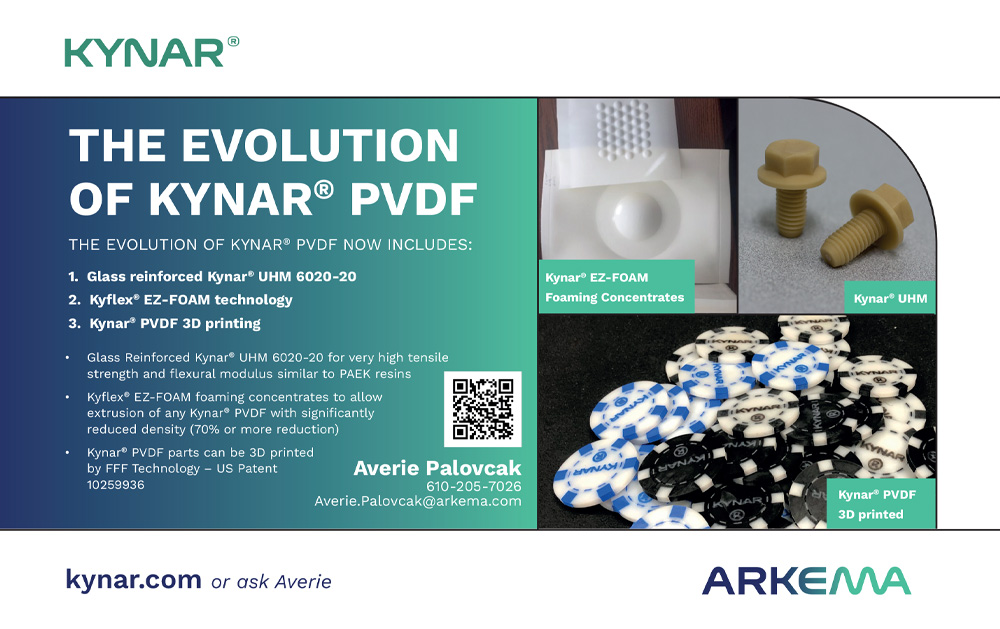

While being educated in many different materials, the polymer family the authors are most familiar with is polyvinylidene fluoride (PVDF), which includes PVDF copolymers. This high-performance thermoplastic is known to have excellent chemical resistance to acids, halogens, hydrocarbons and oxidizing agents, even at high temperatures. The UL® RTI rating of this polymer family for homopolymers and copolymers can be as high as 302oF/150oC. It is also well known for extreme weathering resistance in sunlight exposure, retaining its mechanical properties and even the initial color of a coating or a part for more than 40 years1.

Flat Stock

Sheet Stock

Profile Shapes

Fabrication

3311 Enterprise Road

Fort Wayne, IN 46808

SpecialFocus

ast October, The New Yorker published a cartoon depicting a favorite Muppet, Cookie Monster, in conversation with a bespectacled buddy. The caption read “What me want to know is: What are the implications of the supply chain crisis for cookie?” Humorous and striking at the same time, this cartoon shows that the term “supply chain” had become part of the common vernacular.

Whether you distribute imported product or not, the source of most international and domestic supply chain issues from production to final delivery is at the ports. Just think of that “butterfly that flaps its wings in the Amazon (and causes a series of catastrophic changes elsewhere)” story and apply the principle to “a container gets loaded in China or Rotterdam or Santos or Los Angeles.” The process is complex and a seemingly minor event in one part of the system can cause untold problems elsewhere.

SpecialFocus

efore anyone had even heard of COVID, IAPD members were grappling with a shortage of available means of transporting their materials. At the time, the IAPD Supply Chain Efficiencies Task Force had just formed to identify ways in which to improve the efficiency of the performance plastics supply chain. However, they quickly realized that transportation was an issue: rates were increasing, capacity was decreasing and so the task force shifted their focus to finding ways in which IAPD members could adapt. They recognized that often IAPD members are not shipping “ideal freight,” so they developed these guidelines to offer some insight and guidance. Fast forward to today, and the issue has only compounded. However, the advice in this message is still helpful and, thus, we are sharing an updated version of the task force’s findings here.

APD has heard from you that attracting employees to the performance plastics industry is a challenge. To help, IAPD volunteers have been working on task forces designed to study issues our members are having in attracting, recruiting and retaining professional-level and skilled trades employees. One discovery made during this process is that companies look at hiring as an ongoing, consistent activity, rather than something that starts when a position needs to be filled and stops when a candidate is found. The work of the task forces is designed to help your company meet your hiring goals.

he IAPD Recycling Task Force formed in 2021 to identify ways in which we can approach recycling as an industry. The task force found that most IAPD members are handling materials responsibly: Manufacturers with zero-waste policies capture trim and shavings, returning it to the beginning of their processes. Many distributors and fabricators manage their scrap carefully and are able to send it back to their manufacturer partners. The task force agreed to collect best practices used by the companies that have mature programs that others can use to start a program of their own or make improvements to their current practices.

he material extrusion method of additive manufacturing using filaments, also known as fused filament fabrication (FFF), was patented in 1992. This method of 3D printing takes a thermoplastic feedstock in filament form, pushes it through a hot nozzle and deposits the melted plastic in a specified pattern layer-by-layer until the part is finished. FFF has gained popularity and rapid adoption due to the simplicity of the technology, availability of inexpensive printers and the ability to use a variety of polymers and polymer composites. Multiple colors or even different materials can be printed in the same part design. FFF is suitable for prototyping, jigs and fixtures, or for repairs where quick access to on-site replacement parts is desirable. Figure 1 shows an example of FFF printing.

Josh Elliott Adam Werynski