Table

of

Contents

Differentiation and Value Creation

Industry with Help of IAPD Members

Cover design by Mackenzie Diekmann, IAPD Senior Multimedia and Design Manager.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10% post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

Driving Success:

The Important Role of Differentiation and Value Creation

IAPD President

s I write my first article of 2024 for Performance Plastics magazine, I can’t help but reflect on what seem to be the biggest challenges facing our industry as a whole, and especially the distribution channel.

During the convention in October, we updated attendees on the work of the IAPD Board Strategy Task Force. We surveyed a number of IAPD member company leaders, along with past and present board members, to ask what their greatest challenges are that IAPD could help with.

The three most common things we heard were:

- Workforce Development – Attracting and retaining people, especially the next generation

- Sustainability – Understanding this complex challenge, including ESG

- Government Relations and Plastics Messaging – Educating policymakers and the public on the benefits of performance plastics.

Publisher’sPerspective

CELEBRATING FABRICATION AND INNOVATION IN IAPD

IAPD CEO

History of Fabricators in IAPD

remember when I first joined IAPD in 2006, the word “fabricator” brought out a host of emotions from many of our members. The question of whether IAPD would allow fabricators into the membership and how I would resolve that issue was posed to me during the interview phase of my hiring as CEO. This very question plagued the IAPD membership and Board of Directors for over 20 years and it was one of the very first things I was directed to solve. They wanted my answer before I had even been offered the position.

It wasn’t long after I started in my role as CEO of IAPD that I learned the big secret of that time: Many of our distributors also fabricated as a substantial part of their business mix. For many, they either couldn’t remain profitable doing only wholesale distribution, or the opportunities that they found in adding fabrication services — beyond the traditional value-add — to serve their customers just made sense.

News

Renovo-MPC available exclusively from Interstate Advanced Materials

The Renovo line, available exclusively from Interstate Advanced Materials, includes recyclable and sustainable plastics made from post-consumer and post-industrial material. Renovo-MPCTM is a more sustainable alternative to general-purpose polycarbonate, retaining the same material properties including optical clarity, low haze and high light transmission. Renovo-HIPSTM is an alternative to standard high impact polystyrene (HIPS) made with 25% post-consumer recycled material while maintaining the same properties, thermoformability and adhesion of ink and paint.

PlasticsWatch

Top Five Robot Trends for 2024

Predictive AI is another form of artificial intelligence that can be used in conjuncture with robots to improve efficiency. Predictive AI can analyze robot performance data to anticipate the future state of equipment. Using predictive maintenance can reduce machine downtime, leading to massive cost-savings. Machine learning algorithms also have the capability to analyze data from multiple robots performing the same function for optimization.

Showcase

SABIC via LinkedIn

Developments from SABIC include front wing endplates formed with a 3D printing process. These wings help reduce drag and improve the vehicles downforce and stability.

Wind deflectors made with coated thermoplastic sheet produces with an extrusion process using SABIC LEXANTM resin help improve airflow and decrease drag.

SABIC’s CYCOLOYTM (PC/ABS) resin has been implemented in wheel fins to said break cooling and reduce drag for better stopping power.

Atlanta plastics charity golf tournament uplifts industry with help of IAPD members

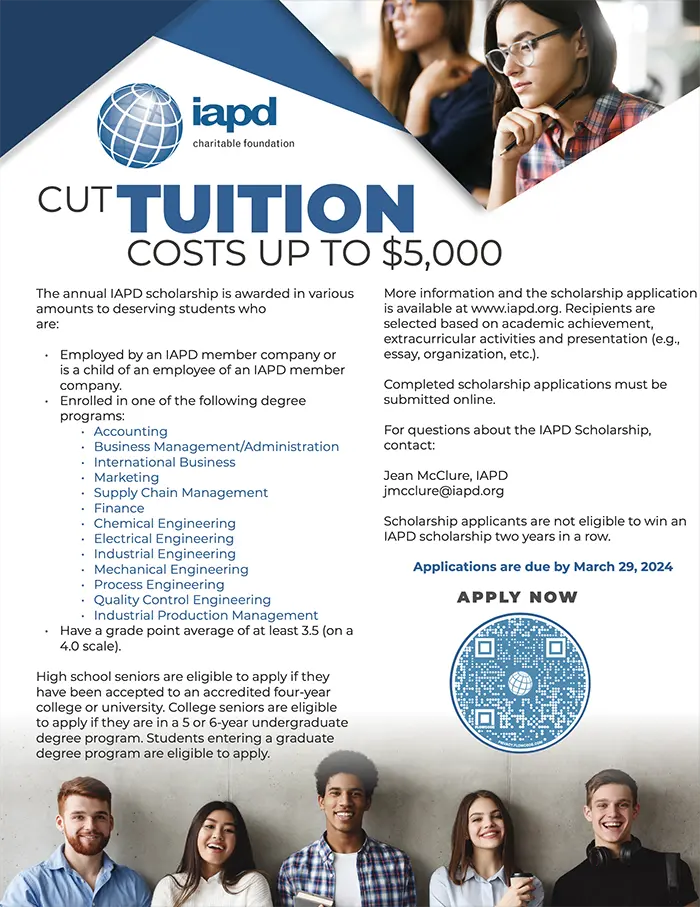

o support individuals in need within the plastics community, local charities and the Greg Berry Scholarship Fund offered by IAPD, is the driving mission behind the Annual Atlanta Plastics Charity Golf Tournament. Over the past 33 years, the mission has been successfully realized with more than US$375,000 raised for the industry and, throughout the past decade, over US$40,000 worth of scholarships raised and distributed through the IAPD Scholarship Program.

In 2024, the committee behind the tournament is aiming to keep the momentum going. The 34th Annual Atlanta Plastics Charity Golf Tournament will be held May 20, 2024, at Chateau Elan in Braselton, GA USA. Ahead of the tournament a welcome reception will be held on May 19.

For registration details or more information about the tournament, visit www.atlantaplasticscharity.org/registration

Understanding the Multi-generational workforce:

Who are the Generations, and how do their leadership styles and expectations differ?

esearch conducted by Harvard in 2019 highlights the financial advantages for companies that effectively manage multigenerational workforces. Successful leadership can generate a sense of belonging that correlates with a 56% increase in job performance, a 50% drop in turnover risk and a 75% reduction in sick days. Today, the Performance Plastics Industry is challenged to manage four generations concurrently, resulting in a higher turnover and challenges to recruit new employees.

Who are these generations, and how can organizations attract and retain all of them simultaneously?

SpecialFocus

Fabrication

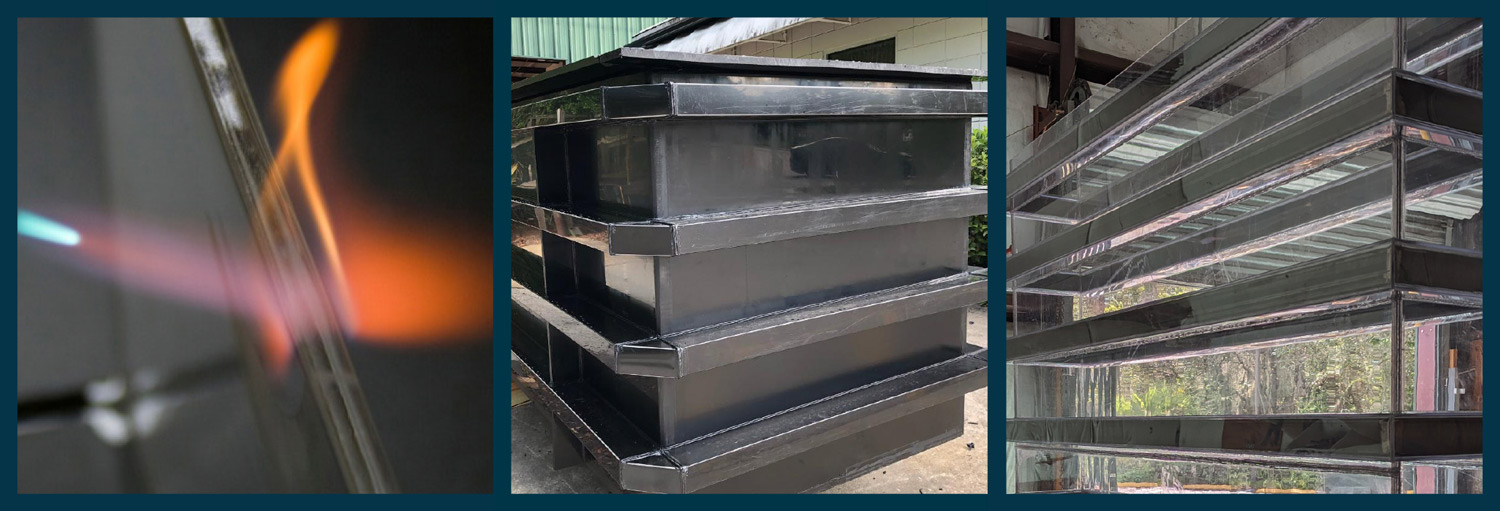

by Allan Harari, PT. Margacipta Wirasentosa

ou can get technical about fabricating see-through substrates, but whatever the process, tools, mechanics, adhesives, compounds or materials, the results are ultimately governed by the aesthetics.

Machine and medical device covers, equipment guards, testing equipment, aquariums, terrariums, emporiums, display stands and boxes for food or cosmetics; each of these must offer a clear view without imperfection. This article focuses on fabricating with the most common see-through substrates.

The Materials

SpecialFocus

Thermoplastics change the game for tank fabrication

Fabrication

by Paige Kistner, Seelye Acquisitions, Inc.

n the realm of tank fabrication, thermoplastics have emerged as a game-changer, offering a versatile and innovative solution for custom manufacturing. One of the major benefits of fabricating with thermoplastics is the flexibility that it offers in design and production.

Fabricating with thermoplastics has become somewhat of an art form throughout the years. With the numerous options one has to fabricate using thermoplastics, designing with plastics is now almost limitless.

20 foot water holding tank fabricated by DJ Plastics, a division of Seelye Acquisitions, Inc.

Tank applications

Deciding which procedure will work for your application depends on a number of factors. An important aspect when choosing the proper fabrication process for a tank is the durability and longevity. A water tank being installed in a RV or Custom Coach for instance needs to be durable. If the tank cannot handle being jarred or having fluid sloshing constantly the user is going to find that the tank will not hold up well and there will be additional costs repairing. So, purchasing a thinner wall roto-molded tank may not be a good choice for this application; while, a custom fabricated butt, extruded or bead welded tank may be.

SpecialFocus

FABRICATION

Jim Bullis, Thermwood Corporation in an interview with IAPD

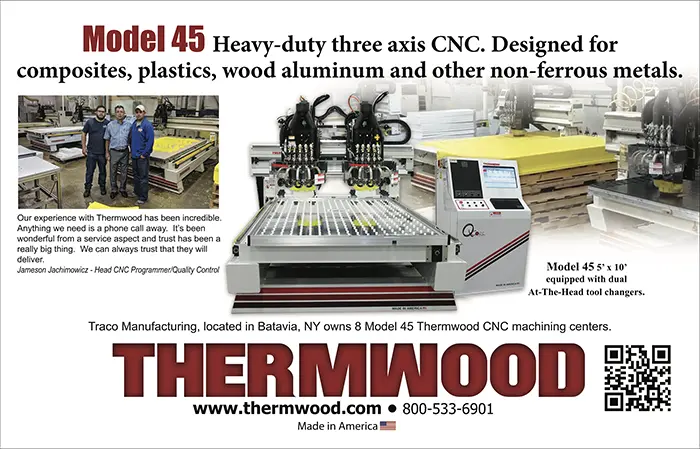

NC routers are extremely popular among performance plastics fabricators with nearly endless combinations of machines, tooling and configurations that can be tailored to suit most any plastic. Additionally, CNC routers offer high-level precision paired with faster cycle times with proper configurations.

To have success with CNC routers in performance plastics, fabricators must consider machine and router bit selection, part hold-down, maintenance and safety.

Jim Bullis, Vice President of Sales at Thermwood Corporation offers insights from his nearly 30 year-long career in 3/5 axis CNC routers in plastics applications and Large Scale / Large Format 3D Polymer Printers.

SpecialFocus

Fabrication

by Kent Kerns, Atlas Saw & Tool, LLC

nderstanding the material you are working with and the machines you are using to make cuts is the most important part of sawing plastics. This information is used to select saw blades that can achieve the cleanest cuts without chipping or melting materials. Using our knowledge and experience, we would like to share with you four categories of blades designed for different performance plastic materials. Each category has blades with different tooth geometries and tooth counts to help you succeed in your cutting process.

Acrylic blades

Cast and extruded acrylics, polycarbonate and PETG: ATB+R (Alternate Top Bevel + Raker Tooth) this aggressive tooth geometry creates a shearing action rather than a plow action to prevent blow out or chipping on the bottom of the cut, while leaving a clean finish in the field. Blade tooth count ranges from 80 to 120 teeth depending on thickness of the material. Blades with higher tooth count are better suited for thin materials, while lower tooth counts are better suited for thick materials.

Fabrication

SERVICES SHOWCASE

Fabrication Services Showcase contains paid listings of companies with fabrication services, products and machinery that cater to the performance plastics distribution industry. IAPD does not endorse nor make recommendations in regard to the companies supplying their services. For details and pricing information to include your company in this Fabrication Services Showcase, contact Dave Blackhurst, IAPD’s Sales Executive, at (913) 345-1005 or email dblackhurst@iapd.org.

CNC Equipment

Places

Trevor Dodge

Steve Ferrero

David Kendall

Professional Plastics, Inc. announced the promotion of a long-time employee and welcomed eight new team members.

New Inside Sales Representative in Portland, OR, USA, Trevor Dodge, will cultivate business with both new and existing clients through proactive outreach and discovery. With a wealth of sales experience exceeding 15 years across diverse industries, including his most recent roles in mortgage and advertising, Dodge brings a wide-ranging perspective to the team. He looks forward to helping the Portland team drive growth and continue to develop strong connections in the northwest United States.

David Kendall, newly appointed Business Manager of the company’s Salt Lake City, UT, USA distribution and fabrication facility, will oversee all branch activities. With over 20 years of experience in distribution sales and management, including several in the plastics industry, Kendall is well-prepared to lead the dynamic team at this location. His strategic approach to sales and operations, along with a proven track record of success, position him as a valuable asset to the team.

REP BUSINESS

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Artek, Inc. • (260) 484-4222 • www.artek-inc.com

Champion Fiberglass • (281) 655-8900 • www.championfiberglass.com

Hendrick • (978) 741-3600 • www.hendrickmanufacturing.com

Hudson Extrusions, Inc. • (800) 837-6015 • www.hudsonextrusions.com

King Plastic Corporation • (941) 493-5502 • www.kingplastic.com

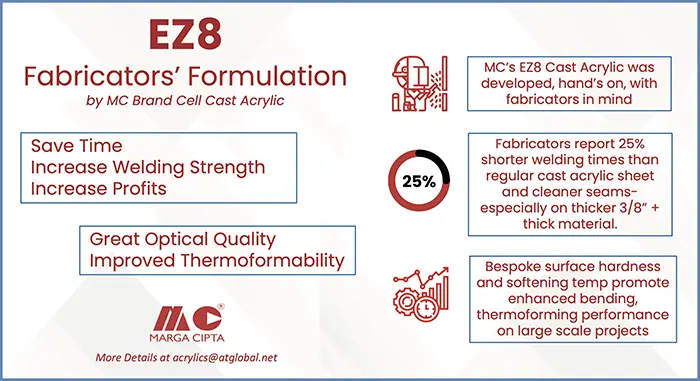

Margacipta Wirasentosa PT. • (201) 871-3610 • www.margacipta.com

Petro Extrusions Technologies, Inc. • (908) 789-3338 • www.petroextrusions.com

Polymer Industries • (256) 657-5197 • www.polymerindustries.com

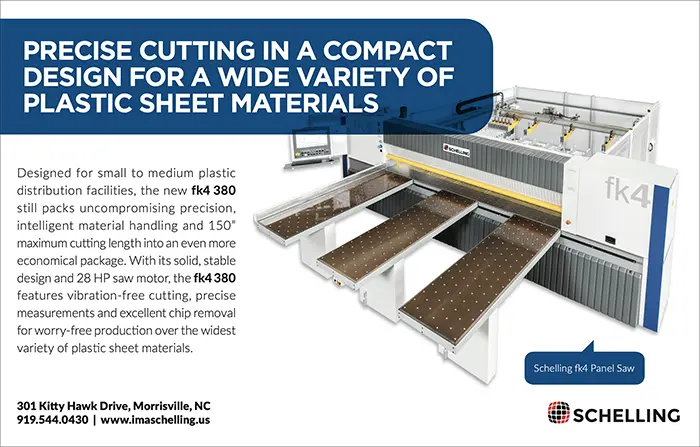

Schelling America, Inc. • (919) 544-0430 • www.imaschelling.us

Thermwood Corporation • (812) 937-4476 • www.thermwood.com

Wegener Welding, LLC • (630) 789-0990 • www.wegenerwelding.com

Vortex Tool Company, Inc. • (715) 355-7707 • www.vortextool.com

BoardofDirectors

Michelle Betz • Alro Plastics • Jackson, Mississippi, USA

Karen Brock–Amoah • SIMONA Boltaron • Newcomerstown, Ohio, USA

Jeff Burke • Curbell Plastics, Inc. • Orchard Park, New York, USA

Chris Corona, Executive Committee • CartierWilson LLC • Solon, Ohio, USA

Peter DelGado, President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Dale Delmage • Redwood Plastics and Rubber • Langley, BC, Canada

Kevin Duffy • Vycom, Scranton, Pennsylvania, USA

Stephen Garmon • Primex Plastics Corporation • Richmond, Indiana, USA

Hayden Hess • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Advanced Materials • Sacramento, California, USA

Richard Miller • Braskem • Philadelphia, Pennsylvania, USA

Jim Richards, Vice President • PLASKOLITE • Columbus, Ohio, USA

Drew Schwartz, Executive Committee • Colorado Plastics • Louisville, Colorado, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

IAPD — the performance plastics association

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Publisher

Susan E. Avery, CAE

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Publishing

Headquarters

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE

savery@iapd.org

Editor

Sara Marquardt

smarquardt@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Editorial Committee

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA