66TH ANNUAL IAPD

CONVENTION PREVIEW

One material for all

detection methods – VMX

VMX products improve the safety and integrity of processingoperations and food quality – having superior mechanical properties to help improve overall production efficiencies.

- Acetron® VMX POM-C

- TIVAR® VMX UHMW-PE

- Nylatron® VMX PA6

- Ketron® VMX PEEK

of

Cover design by Mackenzie Diekmann, IAPD Design and Multimedia Manager.

Energy

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

at Convention

IAPD President

he textbook definition of a convention is: A gathering of individuals to discuss a certain topic or participate in activities related to a shared interest or field. Conventions are often held to bring business or industry professionals together to discuss important issues or topics in their fields. That might be accurate, but it sounds pretty boring to me! The IAPD convention is so much more. It’s an exciting time where industry professionals meet with their peers who have also become their friends and discuss all that is going on in the plastics industry. Let me try to tell you what the convention means to me.

I can still remember the first IAPD convention I had the pleasure of attending. It was in Toronto, ON, Canada and to a southern girl who had never left Alabama, much less the United States, just the idea of going to Toronto was exciting. We arrived in Canada and were swept away to the car to take us to the hotel and convention center. Upon arriving at the hotel, we noticed a group of picketers. What were they doing? They were picketing against the Americans who were coming to Canada! Beyond that, I had no idea. The only thing that stuck with me that day was that I was an American, and I was in Canada. They were picketing against me! We went upstairs to our rooms and quickly unpacked and left for the opening party. Imagine my surprise to find it was located in a castle!

New Ways to Network

IAPD CEO

he 66th Annual IAPD Convention and connecX is right around the corner. We can’t wait to see you at the JW Marriott in Tampa, FL, USA on September 12-15. If you haven’t been to the convention in the past few years, we hope that you take advantage of all the ways that you can connect with current and potential business partners. This is the one time of year that the leaders throughout the performance plastics industry will be in one place, and they are there to meet and connect. IAPD is pleased to offer some new and different ways to connect this year.

If you arrive on Monday, September 12, head to the lobby bar for a no-host happy hour. It’s the unofficial meeting spot for IAPD members looking for other IAPD members. Say hello to people you might not have seen for a few years, enjoy the surroundings and make plans for dinner at one of the many restaurants within walking distance.

Articles reporting on plastic products are prepared from information furnished by members of the IAPD and non-member magazine advertisers. The information provided is deemed reliable but is not verified. It should not be assumed that the publisher has reviewed or tested any of the products. For more information, contact companies by visiting their websites.

Air-Pro® compressed air piping system warranty

Since 1992, the piping system has been made from specially formulated polyethylene (PE) resin, which has antioxidant properties that can withstand the demanding application of compressed air. Air-Pro’s thermoplastic material is also resistant to compressor lubricants and atmospheric corrosion from chemicals or marine environments. Full warranty details are available at www.asahi-america.com.

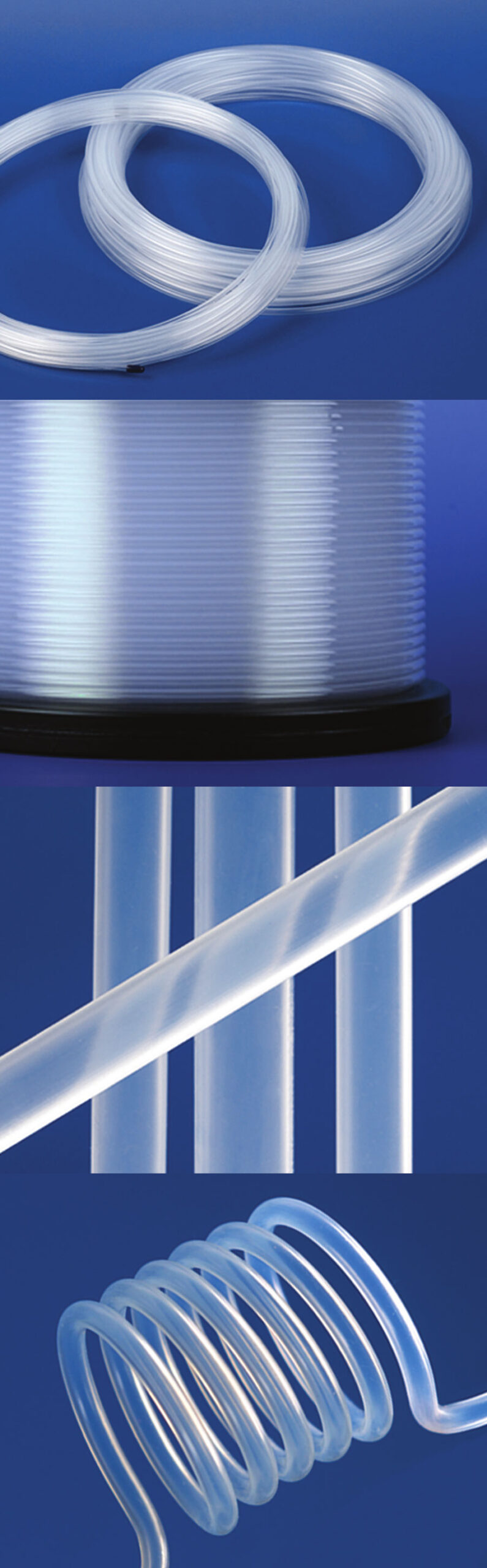

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

FEP

FEPPE

PFA

HP PFA

UHP PFA

PVDF

PVDF FLEX

THV

NYLON

PE

PUR

Dempsey oversaw the project to its completion in early 2021. The greenhouse, measuring 36′ wide by 42′ long, was last remodeled in 1987. It sits in Berkeley’s Botanical Garden, a 34-acre space filled with more than 12,000 different plant species and serves as a museum for visitors to enjoy the numerous plants growing inside.

EnvironmentalCorner

f you are like me, the days can be long, but the years are REALLY short. I have a reminder each year to let me know when we purchased our building; the anniversary has just passed and I was surprised to realize that it’s been 11 years! When we purchased it, the building had been vacant for many years and required us to replace just about everything but the structure. We worked hard with our project manager to install energy efficient materials and equipment…but that was 11 years ago. It hit me hard that we need to reassess the plant and its energy consumption, especially in an environment where energy costs continue to rise.

Technology has changed leaps and bounds since then and the equipment we have is no longer as efficient as we think. For example, in the last 10 years, LED lighting went from producing 50 lumens per watt to 100 lumens per watt and in the next few years, it is projected that they will produce 200 lumens per watt! All IAPD members, distributors, manufacturers, recyclers and sales representatives use lighting to some extent. Just think of the energy savings that we as an organization could save if we were all on the most efficient lighting schemes for our spaces.

SpecialFocus

n November 15, 2021, President Biden signed into law the Infrastructure Investment and Jobs Act (IIJA) — a once-in-a-generation investment in our nation’s infrastructure, competitiveness and communities. This bill is a historic opportunity to rebuild America’s roads, bridges and rails; expand access to clean drinking water; ensure that every American has access to high-speed internet; to tackle the climate crisis and advance environmental justice, while investing in communities — urban and rural — that have too often been left behind.

Key to the IIJA is the inclusion of provisions to expand domestic preference procurement policies. The IIJA directs the application of “Buy America” domestic preference policies to federal financial assistance programs for infrastructure. This provision is designed to provide financial assistance programs for infrastructure not currently subject to these laws, as well as to those that are currently subject to Buy America laws that may be limited in scope to specific materials or products. The new statutory direction is not limited to the funds appropriated or authorized in the IIJA; rather, it directs the application of Buy America requirements to federally funded infrastructure programs and ensures that federal financial assistance programs for infrastructure require the use of materials produced in the United States, increase the requirement for American-made content and strengthen the waiver process associated with Buy American provisions.

he international shipping trade is under intense pressure to reduce its greenhouse gas emissions (GHG). With current levels of CO2 production at about 1 billion metric tons per year, the maritime industry has a larger carbon footprint than the entire Federal Republic of Germany. In response, the International Maritime Organization (IMO) has set an ambitious goal: a 50 percent reduction in total marine industry GHG contributions by the year 2050.

Within that overall framework, shipbuilders and their suppliers are free to experiment with a wide variety of strategies for reducing fossil fuel consumption. Energy efficiency is the order of the day, as engineers and technicians strive to lower costs and meet industry targets. In this light, the HVAC systems of passenger vessels have come under increased scrutiny.

SpecialFocus

ince 2009, towns around Lake Geneva, Switzerland have used the lake to create thermal networks to supply heating and cooling for local buildings. The technology works by exploiting the static temperatures at the lower depths of the lake with a heat pump on land to supply heating more efficiently during winters and cooling during summers. The technology can reduce energy usage for heating and cooling by up to 50 percent, providing an environmentally friendly alternative to traditional techniques.

Project GeniLac was one of the first projects to use the lake’s unique properties, connecting the United Nations district buildings to the system. In 2016, a nearby municipality took a similar approach in La-Tour-de-Peilz to heat more than 400 homes. By 2018, leaders expanded the GeniLac system to support the Geneva city center and seven other municipalities, serving approximately 50 buildings.

In 2021, Centre Patronal sought to build a new employer center in Lausanne to cool and heat the building with the same hydrothermal technology.

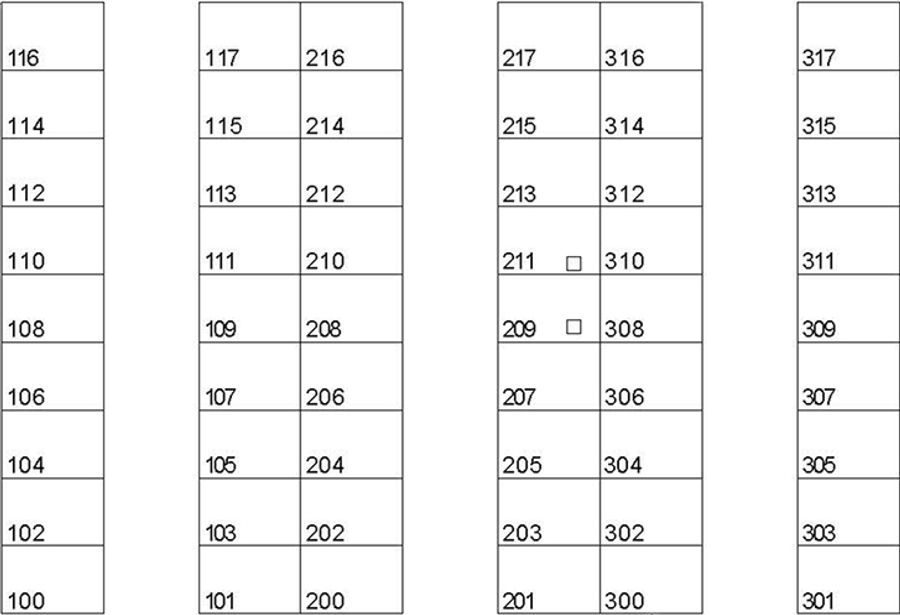

Convention Preview

Here are some highlights planned for this year:

- Two exciting keynote presentations: Hear from Alan Beaulieu of ITR Economics as he reveals strategic business strategies for prospering through the changes in 2023. The second keynote speaker, Alan Stein, Jr., will show you the keys to raising your leadership performance and amplifying your impact and influence. You won’t want to miss them!

IAPD brings the performance plastics distribution supply chain together, making this event the most cost-effective marketing and relationship-building opportunity for your company. Imagine having a full year’s worth of sales meetings with your most valuable customers all in one week!

SEPTEMBER 12

Attendees will learn to:

- Determine the why

- Prepare the organization

- Build the team

- Launch and evaluate the program

- Continually improve on the Continuous Improvement Process

About Chris Ranallo

Chris Ranallo leads Ensinger’s North and South American business units, which are headquartered in Washington, PA, USA.

An ORAFOL Company

to our

Alex Buyea Stacey Rakestraw

Zach Jacobs was named the new business manager for the company’s Seattle, WA, USA branch. Jacobs has steadily excelled with the company over the last six years, most recently as sales manager. He now manages the day-to-day functions of the branch and develops both sales and operations to sustain continuous growth. He looks forward to the added responsibilities of managing the business and strategizing on how to leverage opportunities in the region. His knowledge of the company’s customers, product portfolio and local market position him for success in his new role.

Sarah Johnson was promoted to business manager in San Jose, CA, USA. In her new role, Johnson is responsible for developing, managing and driving a business plan for the fabrication branch that generates growth and maximizes net profit. She plans to accomplish this while maintaining a safe and efficient work environment. With more than 18 years in the plastic industry, the company believes that Johnson is a great fit for this new leadership position. According to Johnson, “The best way to show you’re a leader in the business world is by taking care of your team.”

“We are excited to welcome the Plastics Plus team to the Piedmont family,” said Tyler Booth, president of Piedmont Plastics. “Expanding our presence in Western Canada will allow us to strategically grow our footprint in the region, while strengthening our relationships with our valued customers.”

The IAPD University Certificate Programs give your employees the necessary tools to succeed in plastics distribution. The Performance Plastics Certificate Programs provide a foundation of knowledge about how plastics are made, the Excellence in Sales Certificate Level I Program for inside and outside sales teaches sales forces how to find and keep the RIGHT customers and the Excellence in Sales Level II intermediate program concentrates on correctly defining real-world problems and devising effective solutions for them. The Sustainability Certificate Course raises awareness of the environmental sustainability of performance plastics. IAPD is pleased to announce the latest graduates of these programs:

Campo

Campo

Jermolowicz

Lutz

PATRONS — $5,000-$5,999

PlasticsWatch

Receivables over 30 days were 1.6 percent, down from 2.1 percent the previous month and down from 1.9 percent in the same period in 2021. Charge-offs were 0.12 percent, up from 0.05 percent the previous month and down from 0.30 percent in the year-earlier period. Credit approvals totaled 76.8 percent, down from 77.4 percent in April. Total headcount for equipment finance companies was down 3.0 percent year-over-year. Separately, the Equipment Leasing & Finance Foundation’s Monthly Confidence Index (MCI-EFI) in June is 50.9, an increase from 49.6 in May.

Thanks for reading our August/September 2022 issue!