Table

of

Contents

Business Dress Codes

Excellence Award Winners

San Diego, USA

Special Advertising Supplement

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10% post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

President’sMessage

This article is excerpted from Deborah Ragsdale’s outgoing president’s speech, delivered at the 67th IAPD Annual Convention in San Diego, CA USA, October 23 – 26, 2023.

by Deborah Ragsdale, Polymer Industries

Outgoing IAPD President 2022 – 2023

wo years ago, in Louisville, Kentucky, I stepped up on a stage and thanked you all for the opportunity you had given me to serve as president of this association. I was slightly overwhelmed with the very thought of it, and without all the planning and help available through the staff of the IAPD and the volunteers associated with it, I most certainly would have failed. I have realized over the past few years as the vice president and then president, how much is needed from all of us to keep the plastics industry from giving in to the bad publicity and politics surrounding the name “plastics,” and to keep trying to get the message about all the good we do and the benefits of plastics in the world today. I have seen the industry fight adversity and time after time initiate a campaign to prove the “right” side of the industry. All of those incidents that I have seen have reminded me of a parable I once heard. A story about overcoming hardship and pressing onward regardless of what we are facing.

This parable is told of a farmer who owned an old mule. The mule fell into the farmer’s well. The farmer heard the mule praying or braying or whatever mules do when they fall into wells.

Editor’sPerspective

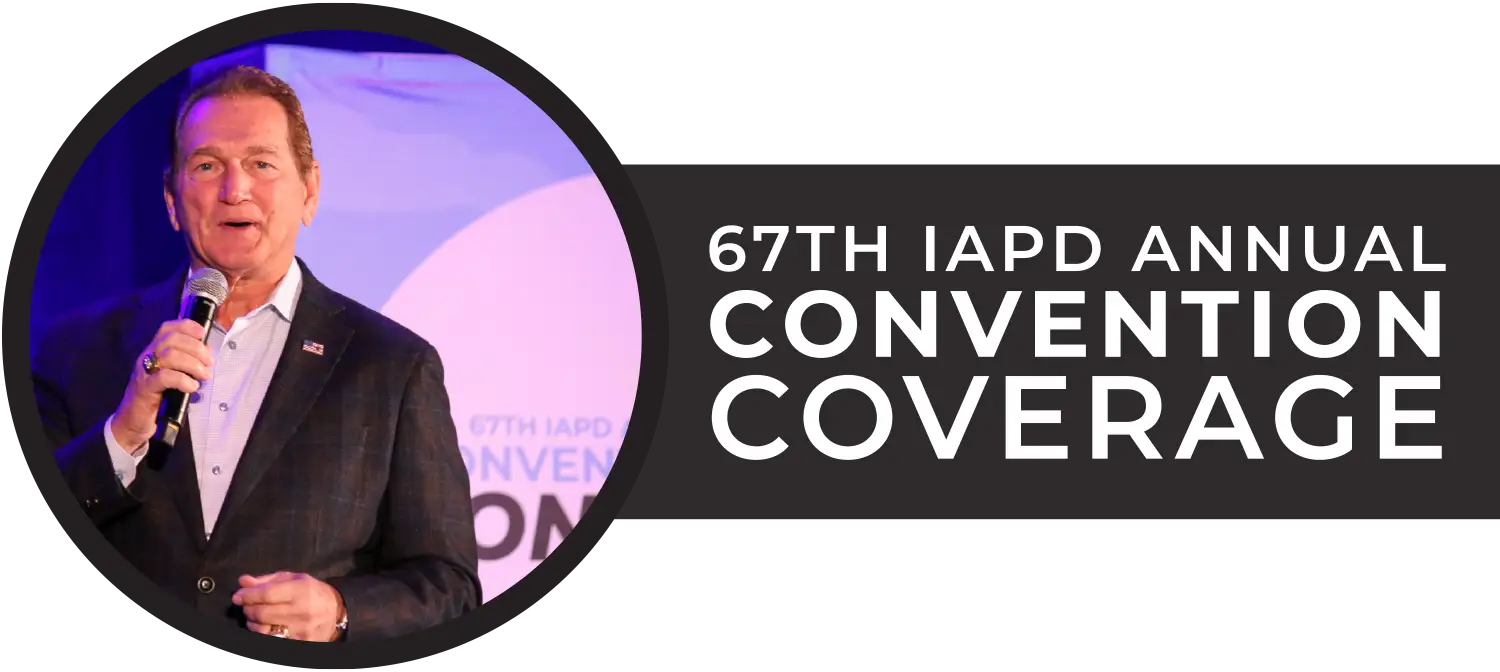

This article is Peter DelGado’s incoming president’s speech, delivered at the 67th IAPD Annual Convention in San Diego, CA USA, October 23 – 26, 2023.

by Peter DelGado, Curbell Plastics, Inc.

Incoming IAPD President 2023 – 2024

’m Peter DelGado, Senior Director of Sales and Customer Service at Curbell Plastics, and your current IAPD Vice President.

I’d like to take a just a minute to let you know a little about me.

I’ve been with Curbell for 37 years and have held many different roles. Those experiences have allowed me to wear a lot of different hats now and, as Keith Hechtel referenced yesterday, become the “Director of Getting ‘Stuff’ Done.”

It has also allowed me to work with so many awesome people at Curbell, especially our Senior Management Team, most of who are here this week. Thank you for being such a great team, and some of my best friends.

I’ve also been privileged to work with so many of you in this room over the years, both in business and with IAPD, and have developed some great friendships. I’ve learned a lot from so many of you. Thank you for all of your support.

Showcase

Through this project Ensigner has launched a new higher-performance plastic named TECASINT 8591 for applications in the space industry, including ball bearing cages in satellites. Use of PTFE with special lubricants and fillers provides the new product with outstanding self-lubrication properties under conditions found in space.

These properties support employee safety, reduce contamination in the event of a fire and help reduce malfunctions or plant downtime.

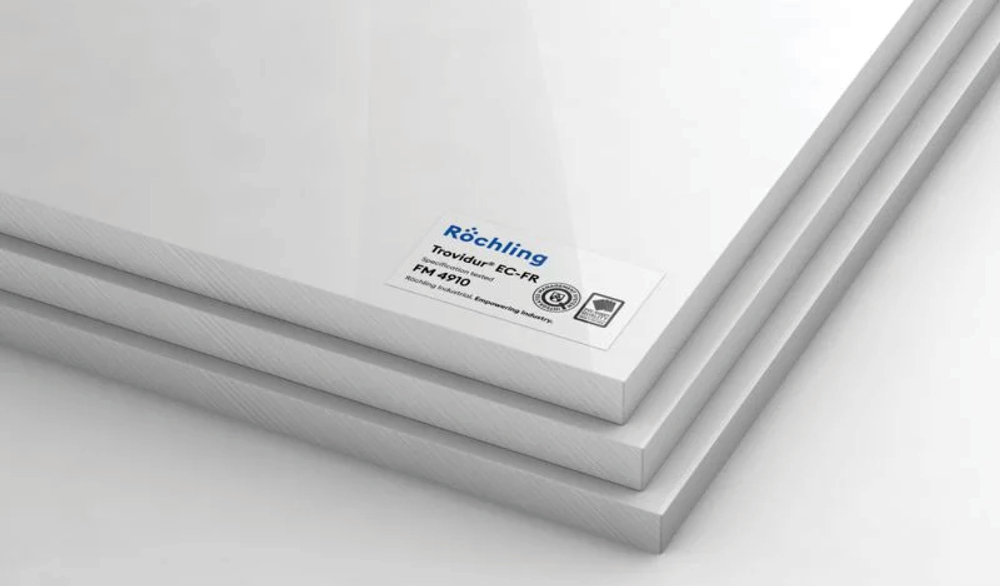

In addition to FM specifications, Trovidur EC-FR White FR1130 also has high chemical resistance, is weldable, bondable, easy to process, has high-quality surface glance on both sides and is easy to clean.

Diversity, Equity, Inclusion and Belonging in Business Dress Codes

by Kenya Smith, Mativ, previously SWM and Mark Trepanier, CartierWilson, LLC

Article five in the DEI+B series by the IAPD Diversity Equity Inclusion and Belonging Task Force

started in the plastics industry in 2000. At that time, women were expected to wear a business suit or skirt with a white blouse. Men were expected to wear a gray, navy or black suit and tie at all times, whether in the office or on the road. Back then, this business attire was called business professional. Your attire aided in identifying what position you held in the workplace, it matched professional stance and/or educational level. Throughout the years dress codes have evolved and four different types of business attire have emerged:

- Business formal – Ultra-stylish attire for formal occasions.

- Business professional – Traditional business attire.

- Smart casual – Professional and casual wear.

- Business casual – Professional attire that is comfortable.

ere at IAPD we strive to celebrate environmental innovations and sustainability efforts from our member companies. The IAPD Environmental Excellence Award was created to honor companies who have gone above and beyond in their dedication to sustainable business practices. Applicants for the award are assessed by the IAPD Environmental Committee based on strategies for recycling, conservation, community outreach, employee engagement and more. As we enter the new year, let’s take a moment to look back on the achievements of the 2023 Environmental Excellence Award winners.

A Gold Level Environmental Excellence Award was presented to Richard Miller and Ed Townsend of Braskem.

Gold – Braskem

Additionally, Braskem continues to implement disruptive technologies that drive sustainable development. In 2022, they entered into an agreement with Compact Membrane Systems in the development of technologies of carbon capture equipment, which can be utilized at our manufacturing sites to reduce emissions of existing processes by at least 90%.

Review

he Women in Plastics program continued to grow and thrive in 2023, traveling across the United States and through our Wi-Fi routers to bring performance plastics professionals together to learn, build connections, get inspired and enhance their careers.

The group also hosted an Education Session in conjunction with the 67th IAPD Annual Convention + connecX in beautiful San Diego, CA.

While visiting each of these cities, Women in Plastics had the privilege of positively impacting their local communities. In Atlanta, attendees took on a landscaping project at the historic Piedmont Park Conservancy.

In Buffalo, attendees worked to sort clothing and food donations at Hearts for the Homeless’ thrift store.

Year in

Review

n 2023 GenerationNext continued to grow as a forum where young professionals and those new to the industry can connect to share ideas, experiences and learn from seasoned industry leaders. We strive to take the pressure out of networking by creating a space that’s designed just for newcomers with support and community at the heart.

Our 2023 lineup of virtual events touched on a wide range of topics to help young professionals build skills to enhance their careers and get inspired.

The year kicked off with a virtual Valentine’s Day networking happy hour, where participants enjoyed a cocktail mailed to them by IAPD and conversation with IAPD Board member, Jeffrey Burke, Curbell Plastics, Inc.

Aliphatic Thermoplastic Polyurethane Films for Advanced Laminated Transparencies

security

by Kenneth Schwartz, Covestro LLC – Specialty Films

ver the past 100 years, a range of techniques and materials have been introduced to provide commercial solutions to render glass stronger and more impact resistant for enhanced security and safety. Today, the most widely practiced approach is a thermal process to “temper” glass to improve strength as well as safety after breakage. Tempered glass is now the standard approach for safety glass used for large glass panels in sliding glass doors as well as shower enclosures.

In the early 20th century, scientists discovered that combining polymers with glass improves impact resistance. Additional processes were developed to make glass even stronger and safer by laminating it to transparent thermoplastics. In the 1920s, industrial production of polyvinyl butyral (PVB) began, which quickly became the material of choice for laminated safety glass. PVB laminates are still used today for automotive front windshields.

Safety first:

Considerations for performance plastics materials in security equipment

security

lastics are widely used in environments requiring safety and security because they are durable, lightweight and resistant to corrosion. Additionally, plastics can be molded into various shapes, making them versatile for applications such as bulletproof glass, security barriers and protective gear. Their ability to withstand harsh conditions and provide impact resistance contributes to their widespread use in security-related products.

To qualify as bullet-resistant, plastics undergo rigorous testing based on industry standards. Some key testing criteria include:

Velocity and caliber requirements: Materials are tested against specific bullet velocities and calibers to ensure they can effectively resist penetration. Different levels of protection may require withstanding different bullet types and speeds.

Deformation: This measures the extent to which the material deforms upon impact. Minimal backface deformation is crucial to prevent injury behind the armor.

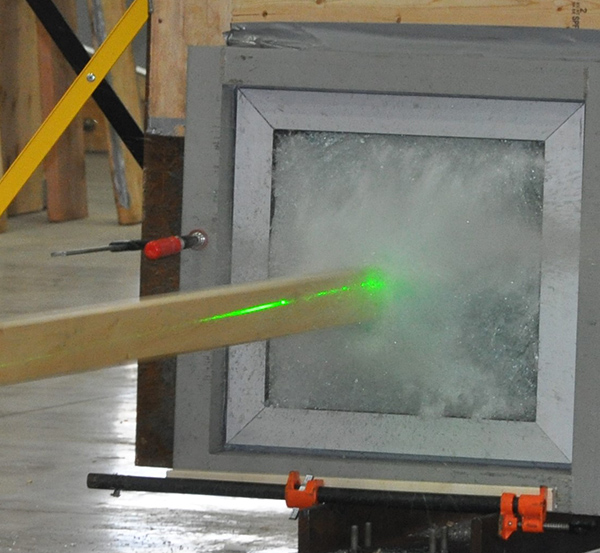

Putting Polycarbonate Glazing to the test

Security

quick look at the latest numbers from the National Centers for Environmental Information will tell you a story worth listening to. In 2015, There were five extreme storms in the United States with a cost of damage totaling over US$1 billion. Just two years later, that number more than doubled with 12 catastrophic national storms. In 2020, the total number of extreme windstorms in the United States reached 20. Exponential is the best word to describe this upward trend. While we are still working on ways to mitigate the financial cost of extreme windstorms, we can now provide better safety, minimizing the impact to human life thanks to performance plastics.

Eight years ago, International Building Code (IBC 2015) standards began requiring new and improved safe rooms of protection for essential buildings. These buildings include schools, hospitals, police stations, fire stations and emergency operation centers with occupancy over 50 persons in areas that face extreme weather with over 250 mph wind. These safe room shelters should be large enough to hold everyone in the building and withstand wind and debris from EF5 tornadoes or Category 5 hurricanes. A key component in these structures is window protection.

APD – The Performance Plastics Association, concluded its 67th IAPD Annual Convention + connecX on October 26th, 2023, at the Sheraton San Diego Hotel & Marina in San Diego, CA, USA. This event welcomed delegates from across the world for a week of critical industry conversations about sustainability, upcoming federal legislation/regulations and market trends, as well as supplier meetings, educational content and professional networking.

In addition to the numerous learning opportunities, delegates experienced new and creative networking opportunities, including social hours and receptions.

The sold-out IAPD connecX showcase was held on Wednesday. It featured booths with meeting areas and an all new IAPD Programs and Committees Showcase outside the trade show floor.

The convention wrapped up with a lively Closing Party at Coasterra, featuring a live band that performed something for everyone. Attendees enjoyed fantastic food and drinks, dancing and conversation!

Save the date: The 68th IAPD Annual Convention + connecX will be held October 7 – 10, 2024 at the Omni Louisville Hotel in Louisville, KY, USA. We look forward to seeing you there!

2023 Special Recognitions and Awards

Paul Davis Award of Merit

connecX TRADE SHOW

The Closing Party

at Coasterra

Places

Valerie

Glover

Glover has a strong background in corporate communications and brand management with a focus on global manufacturing and distribution.

She also holds an M.S. in Management from Northeastern University and maintains active involvement in professional associations such as the American Marketing Association and Women in Manufacturing.

“We are excited to have Valerie as a member of our marketing team,” said Vice President Sales & Distribution Strategy Alicia Spence. “Her passion for marketing and experience with implementing effective digital tools will lead to success in this new role.”

Fabrication

Fabrication Services Showcase contains paid listings of companies with fabrication services, products and machinery that cater to the performance plastics distribution industry. IAPD does not endorse nor make recommendations in regard to the companies supplying their services. For details and pricing information to include your company in this Fabrication Services Showcase, contact Dave Blackhurst, IAPD’s Sales Executive, at (913) 345-1005 or email dblackhurst@iapd.org.

Annual

Corporate Profiles

Spring, TX, USA

10 REASONS WHY PROJECTS NEED CHAMPION STRUT™

hampion Strut is a versatile, high-strength fiberglass framing system that provides durable, corrosion-resistant support for piping and conduit in industrial construction projects.

This channel system is comprised of non-metallic components designed to provide long-term performance in challenging environments including wastewater treatment plants, utilities, chemical plants, marinas, desalination plants and pools.

Here’s how Champion Strut benefits projects:

TECAPEEK ELS nano black

or applications that require a plastic with the added characteristic of electrical conductivity, Ensinger has developed PEEK ELS under the trade name TECAPEEK ELS nano black, using Victrex™ PEEK 450 polymer. This material takes advantage of the addition of carbon nano tubes, which allows for a high degree of conductivity to be achieved while maintaining low levels of filler content. As a result, TECAPEEK ELS nano provides consistent surface resistivity between 102 – 104 Ω/sq, while offering significantly reduced residual stresses compared to carbon fibre reinforced grades, enabling less warpage, and bending during machining. Enhanced dimensional stability is key for achieving the tight tolerances required for semiconductor manufacturing equipment components. In addition, lower internal stress enables faster speeds and feeds, results in faster part production and better yield, which reduces fabrication costs. The outstanding properties of PEEK natural such as excellent thermal resistance (up to 260 C), low CLTE, low moisture absorption, and high strength are retained by TECAPEEK ELS nano black.

manufacturers of quality polycarbonate sheets and panels

allina SRL was founded in 1960 by Pier Aulo Gallina in La Loggia, Italy specializing in plastic trim production for the automotive industry. Over the subsequent years, Gallina has expanded its product lines and developed polycarbonate sheet and system solutions for the architectural and industrial market sectors. Today, the Gallina companies are renowned producers and suppliers in Europe, the Middle East and the Americas, with production facilities and manufacturing partnerships in Italy, Greece, Turkey, the United States, France, Germany and India with key sales partnerships throughout Europe and the United States.

Gallina USA, LLC was established in Janesville, WI, USA in 2002 and currently operates a 150,000-square-foot manufacturing and warehousing facility serving the multiwall and solid sheet polycarbonate needs for the distribution, architectural, industrial, horticultural and do-it-yourself (DIY) sectors.

committed to quality and continuous improvements

ince their inception over 50 years ago, Hudson Extrusions, Inc. has been dedicated to a singular goal: “Total Customer Satisfaction.” They strive to exceed their customers’ expectations through outstanding customer service, quick turnaround times and producing extruded plastic tubing and profiles of exceptional quality.

Having been family owned and operated since 1956, they value the personal service that has become scarce in today’s technologically advanced environment. Their knowledgeable sales staff has a combined 40+ years of experience in the plastics industry and are ready to help with any questions or inquiries you may have.

Our Innovation. Your Imagination.®

ing Plastic Corporation is a leading manufacturer of quality polymer sheets, slabs and massive shapes — including several products pioneered by the company. Its polymers are made in the United States and sold worldwide through a network of top plastics distributors to customers who fabricate products for the marine industry (King StarBoard® brand), signage, food service, healthcare, architectural, industrial and other markets. King Plastic manufactures more than 20 products including:

- King StarBoard® — The original marine-grade polymer sheet

- King StarBoard® AS — The anti-skid marine-grade polymer sheet

- King StarBoard® XL — The lightweight marine-grade cellular sheet

The smart choice for

many high abuse

application

Available in colors: Black and White

The smart choice for many high abuse application

Available in colors: Black and White

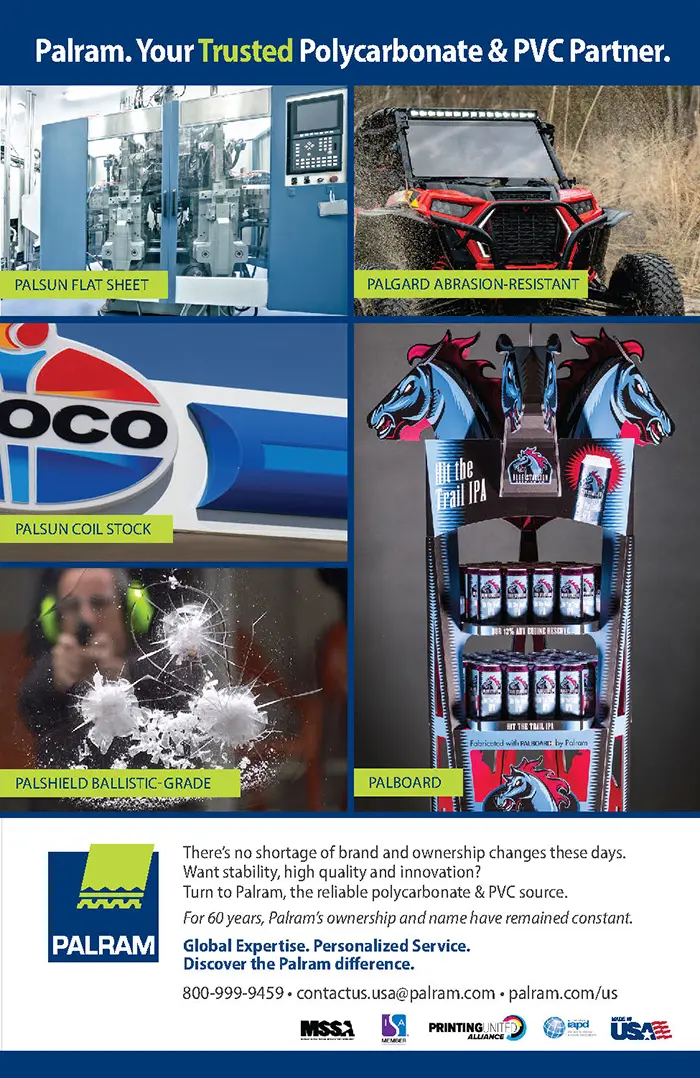

POLYCARBONATE & PVC POWERHOUSE

ith time-tested resources, proprietary technologies, and a rich history of expertise, Palram has become a trusted partner to markets spanning industrial, construction and architecture, safety and security, sign and display, transportation and outdoor living.

From our seasoned sales reps and knowledgeable and responsive customer service team to timely shipping, and broad breadth of offering, Palram is committed to providing world-class service.

Experience the benefits of a nimble, single source supplier of high-quality polycarbonate and PVC.

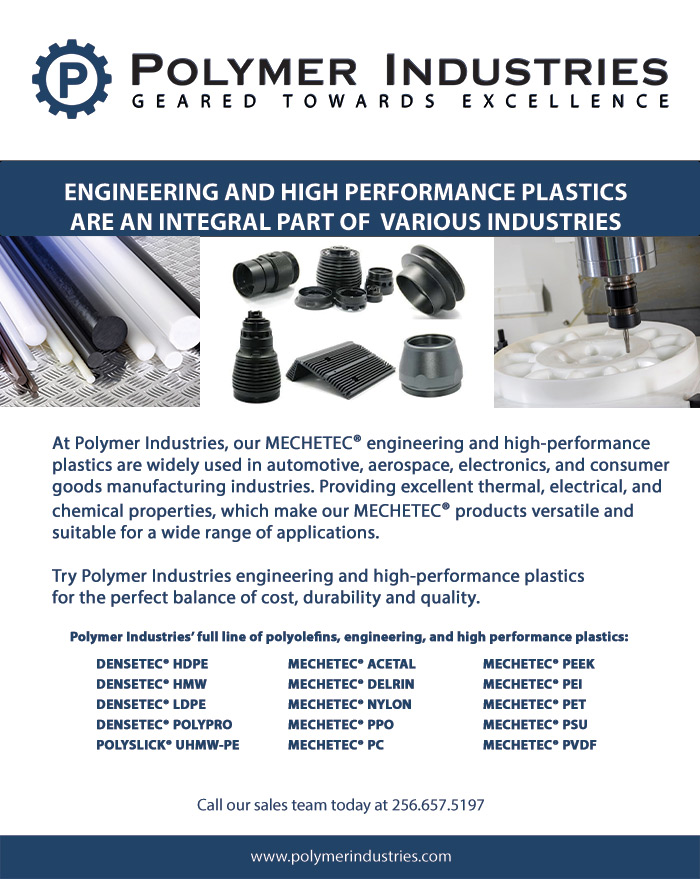

geared towards excellence

olymer Industries is nearing 50 years of manufacturing performance plastics and the quality standards that built the foundation of the company are still in place today. As we have worked hard to accommodate the growing needs of our customers, the company has grown and its product portfolio expanded.

Today, Polymer Industries is proud to offer one of the largest performance plastics product offerings from a single manufacturer. Our polyolefin product line includes Densetec® high density polyethylene (HDPE), polypropylene (PP), high molecular weight polyethylene (HMW), low density polyethylene (LDPE) and Polyslick® ultra high molecular weight polyethylene (UHMW PE).

a global leader in plastics innovation

he Roechling Group, made up of Industrial, Medical, and Automotive divisions, employs over 11,000 worldwide at 91 locations in 25 countries. Backed by a global network, Roechling Industrial North America is one of the world’s leading manufacturers of high-quality semi-finished thermoplastics, engineering products, and composites. Featuring what they believe to be the most comprehensive product line within the U.S., Canada and Mexico, Roechling is committed to developing efficient, innovative, and sustainable solutions for their customers.

Through continuous investments and improvements in new manufacturing technologies, Roechling products are used and specified by engineers and cater to a wide range of industries.

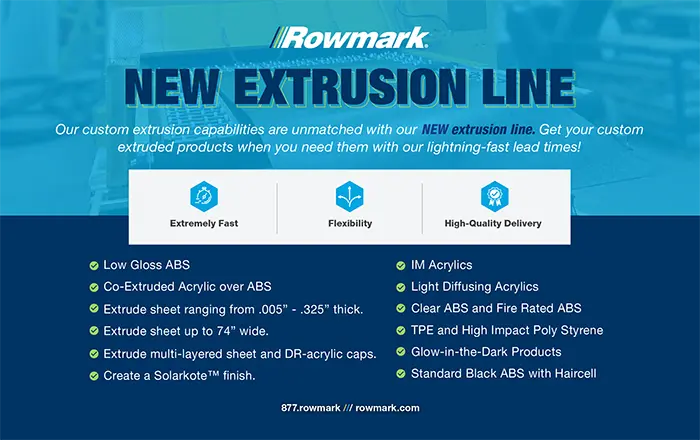

one-stop shop for CUSTOM plastic sheet extrusion

owmark is excited to announce the expansion of its custom extruded sheet products webpage, www.rowmarkcustom.com. Custom products featured include Rowmark’s LD light diffusing product, impact modified acrylic, ABS sheet and thermoplastic elastomer (TPE) materials.

Archbald, PA; Newcomerstown, OH; Findlay, OH, USA

THREE MANUFACTURING SITES IN NORTH AMERICA OFFER A DIVERSE RANGE OF PRODUCTS AND SERVICES TO DISTRIBUTORS

IMONA AMERICA GROUP consists of three independent manufacturing and sales facilities: SIMONA AMERICA Industries, SIMONA Boltaron and SIMONA PMC.

SIMONA AMERICA Industries specializes in extruded olefin, PVC and fluoropolymer sheet, rod and weld rod for a wide variety of applications, including chemical and corrosion tank manufacturing, semiconductor equipment, marine, outdoor furniture, bathroom partitions, food preparation and orthotics and prosthetics.

Burr Ridge, IL, USA

the plastic welding experts

egener Welding, LLC is an international supplier of high-quality welding, processing and testing equipment for thermoplastic materials. Their mission is not only to offer a wide range of quality products, but to ensure that our customers have access to customized solutions, expert advice, training programs, reliable service and support. A dedicated team of knowledgeable personnel are available to aid in defining the proper equipment for the job, as well as finding solutions to any welding problems their customers may have.

In 2006, Wegener Welding, LLC emerged as a new entity out of what was formerly known to the industry as Wegener North America, Inc., which had serviced the market with their range of sheet-related thermoplastic welding and fabrication products since the early 1980’s. The product lines of our partners Wegener International GmbH, Hürner Schweisstechnik GmbH, and Buckleys (UVRAL) Ltd. form a comprehensive source of plastic welding and testing equipment unique to the industry.

AdvertisersIndex

BoardofDirectors

AdvertisersIndex

Alro Plastics • (517) 787–5500 • www.alroplastics.com

Champion Fiberglass • (281) 655-8900 • www.championfiberglass.com

Ensinger • (724) 746-6050 • www.ensingerplastics.com

Gallina USA, LLC • (888) 463-3342 • www.gallinausa.com

Hudson Extrusions, Inc. • (800) 837-6015 • www.hudsonextrusions.com

King Plastic Corporation • (941) 493-5502 • www.kingplastic.com

Norplex-Micarta • (563) 864-7321 • www.norplex-micarta.com

Palram Americas, Inc. • (800) 999-9459 • www.palram.com/us

Polymer Industries • (256) 657-5197 • www.polymerindustries.com

Preston Machinery, LLC • (269) 685-7591 • www.prestonmachineryllc.com

Roechling Industrial Gastonia • (704) 922-7814 • www.roechling.com/us/industrial

Rowmark LLC • (800) 243-3339 • www.rowmark.com

SIMONA AMERICA Group • (866) 501-2992 • www.simona-america.com

Wegener Welding, LLC • (630) 789-0990 • www.wegenerwelding.com

BoardofDirectors

Michelle Betz • Alro Plastics • Jackson, Mississippi, USA

Karen Brock–Amoah • SIMONA Boltaron • Newcomerstown, Ohio, USA

Jeff Burke • Curbell Plastics, Inc. • Orchard Park, New York, USA

Chris Corona, Executive Committee • CartierWilson LLC • Solon, Ohio, USA

Peter DelGado, President • Curbell Plastics, Inc. • Orchard Park, New York, USA

Dale Delmage • Redwood Plastics and Rubber • Langley, BC, Canada

Kevin Duffy • Vycom, Scranton, Pennsylvania, USA

Stephen Garmon • Primex Plastics Corporation • Richmond, Indiana, USA

Hayden Hess • Industrial Plastic Supply, Inc. • Anaheim, California, USA

Jeremy Kietzke • Professional Plastics, Inc. • Dallas, Texas, USA

Mike McKenna • Interstate Advanced Materials • Sacramento, California, USA

Richard Miller • Braskem • Philadelphia, Pennsylvania, USA

Jim Richards, Vice President • PLASKOLITE • Columbus, Ohio, USA

Drew Schwartz, Executive Committee • Colorado Plastics • Louisville, Colorado, USA

Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Publishing

Headquarters

Headquarters Staff

Editorial Committee

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Susan E. Avery, CAE

savery@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Junior Copywriter & Editor

Sara Marquardt

smarquardt@iapd.org

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA

Publishing

Headquarters

The International Association of Plastics Distribution

6734 W. 121st Street

Overland Park, Kansas 66209 USA

Headquarters Staff

Susan E. Avery, CAE

savery@iapd.org

Advertising Sales

Dave Blackhurst

dblackhurst@iapd.org

Senior Design & Multimedia Manager

Mackenzie Diekmann

mdiekmann@iapd.org

Junior Copywriter & Editor

Sara Marquardt

smarquardt@iapd.org

Editorial Committee

Vice Chair • Tony Martin • Palram Americas, Inc. • Kutztown, Pennsylvania, USA

Board Liaison • Ken Schwartz • Covestro LLC – Specialty Films • South Deerfield, Massachusetts, USA

Trisha Beeman • Professional Plastics, Inc. • Bellingham, WA, USA

Paige Bowen • Seelye Acquisitions • Apopka, FL, USA

Peter Daumeyer • CartierWilson LLC • Tampa, Florida, USA

Michael Fabbri • King Plastic Corporation • North Port, Florida, USA

Jeff Mikitka • Mitsubishi Chemical Group • Reading, Pennsylvania, USA

Bryan Olin • Polymer Industries • Tacoma, Washington, USA

Beth Summers • Curbell Plastics, Inc. • Orchard Park, New York, USA

Ed Townsend • Braskem • Philadelphia, Pennsylvania, USA

Amy Woodard • Piedmont Plastics • Charlotte, North Carolina, USA