of

A CLOSE LOOK AT SOME INNOVATIVE COMPANIES SERVING THE PERFORMANCE PLASTICS INDUSTRY

Performance Plastics: A Publication of The International Association of Plastics Distribution is published bimonthly by the International Association of Plastics Distribution® (IAPD), 6734 W. 121st Street, Overland Park, KS 66209 USA. IAPD members receive this bimonthly magazine as part of their membership dues. Subscription for non-members is $90. Third class postage paid at Shawnee Mission, Kansas, additional mailing offices and foreign mailing in accordance with Publications Agreement No. 40683057. POSTMASTER: Please send address changes to IAPD, 6734 W. 121st Street, Overland Park, KS 66209 USA.

This is the official publication of the International Association of Plastics Distribution and carries news and announcements concerning the IAPD. The association and Performance Plastics: A Publication of The International Association of Plastics Distribution are not responsible for content or opinions other than those relating to association activities.

® Registered, U.S. Patent and Trademark Office, by the International Association of Plastics Distribution. All rights are reserved. Reproduction in any form whatsoever is forbidden without express permission of registered trademark owner.

Performance Plastics: A Publication of The International Association of Plastics Distribution is printed on paper with 10 percent post-consumer recycled content.

IAPD • phone (913) 345-1005 • fax (913) 345-1006 • www.iapd.org

IAPD President

ick up any newspaper, turn on a television, or do a Google search on the device of your choice and you’ll see some variation of a story about the transportation crisis. There are bottlenecks at the ports, a driver shortage and fuel costs are rising. On the consumer side, toys and gifts for the holidays are in containers in ships waiting to be unloaded or on the docks among thousands of other containers. There is no more space to put containers. What about the everyday problems that business must face due to transportation issues? These are all issues that impact our ability to serve our customers and threaten bottom lines. The plastics industry is no exception, and it is being hit hard. The good news is that, thanks to having good relationships with your providers, you can find ways to save money and make sure your customers receive the materials they need. As I mentioned during my speech at the convention, relationships can help us get through the tough times. This transportation crisis is just one example.

Editor’s Perspective

IAPD CEO

APD has heard from you that attracting employees to the performance plastics industry is a challenge. To help, IAPD volunteers have been working on task forces designed to study issues our members are having in attracting, recruiting and retaining professional-level and skilled trades employees. One discovery made during this process is that companies look at hiring as an ongoing, consistent activity, rather than something that starts when a position needs to be filled and stops when a candidate is found. The work of the task forces is designed to help your company meet your hiring goals.

The Workforce Development Task Force for Professional Positions focused on sales, marketing, engineering, administrative and other office staff. They developed a framework for IAPD’s talent acquisition strategy that addresses:

- Members’ existing and future workforce development needs.

- Recommendations for where IAPD can provide the best value.

- Resources to support your recruitment and promotional efforts.

- Ways to best promote careers in the performance plastics industry.

KYDEX® 2210LT from SEKISUI KYDEX

ondit has a rich and storied history in the world of exhibit fabrication, going back to 1945. The company offers a full range of design and fabrication services, as well as rental exhibit services, from its headquarters in Denver, CO, USA and satellite location in Chicago, IL, USA.

Among the various materials used to produce custom tradeshow exhibits, the company uses polyvinyl chloride (PVC) and acrylics in a wide variety of applications such as three-dimensional graphics letters and logos, infill panels for its rental wall systems, display cases and decorative finishes. Using a UV flatbed printer, the fabrication team also prints to full 4′ x 8′ PVC sheets, as well as adds printed vinyl laminate graphics depending on the project.

he Women in Plastics leadership planned a full year of events so IAPD members could continue to learn, network and have fun. Read on to learn more about the 2021 programming, and be on the lookout for announcements about what’s planned for 2022.

- When asked to assess their business conditions over the next four months, 34.6 percent of executives responding said they believe business conditions will improve over the next four months, up from 25.9 percent in October. 46.2 percent believe business conditions will remain the same over the next four months, down from 70.4 percent the previous month. 19.2 percent believe business conditions will worsen, up from 3.7 percent in October.

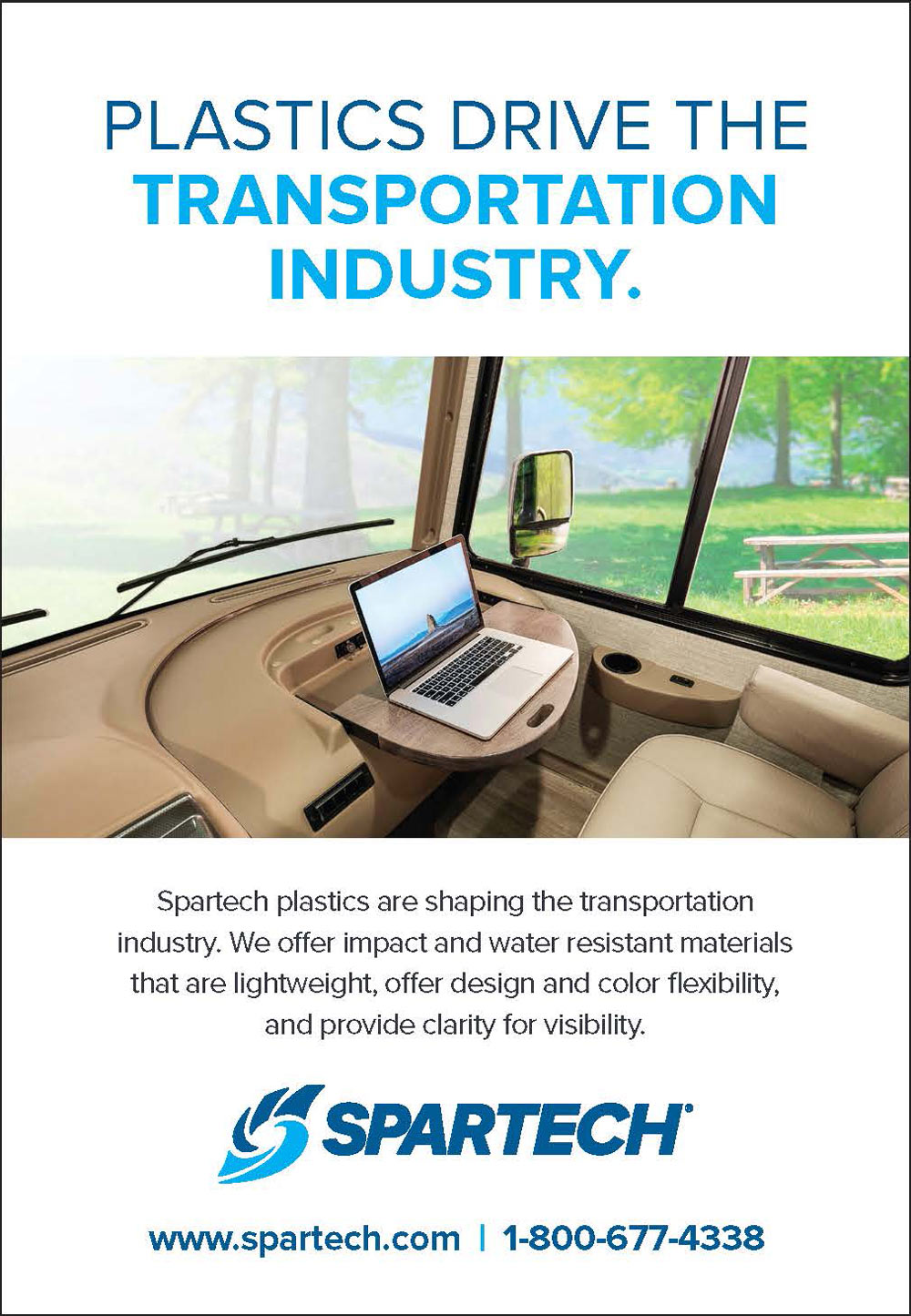

he very term performance plastics embodies the expectations of the transportation industry. It evokes materials that are lightweight for speed, flexible for design, colorful for beauty, impact resistant and anti-microbial for safety, clear for visibility, as well as water and weather resistant. The transportation market is one of the largest manufacturing segments in North America and there are a wealth of potential plastic sheet and film applications for the OEMs and aftermarket segments.

The opportunities for plastic shapes distributors to gain access to the various transportation market segments continue to increase with such megatrends as anti-microbial conditions, increased light-weighting (particularly for the electronic vehicles segments), sound absorption improvements, safety enhancing requirements and the use of sustainable and recycled materials.

Plastic shapes distributors can offer their stocking and fabrication services to multiple levels in the supply chain in the transportation market. As part of the handling of returned scrap and providing regrind plastic, distributors have another possible value-added service in the toolbox.

applications

ltra-high molecular weight polyethylene (UHMW-PE) bus curb facing is a maintenance-free application for protecting curbing, platforms and buses from damage during basic stop and precision docking operations. Use of bus curb facings helps the growing number of bus rapid transit (BRT) systems be more cost efficient, reliable and safer. Many large and medium-sized city transit agencies are investing in BRT systems to better and more cost effectively serve growing public transportation requirements.

According to the National Bus Rapid Transit Institute, “BRT is an innovative, high capacity, lower cost public transit solution that can significantly improve urban mobility. This permanent, integrated system uses buses or specialized vehicles on roadways or dedicated lanes to transport passengers quickly and efficiently to their destinations while offering the flexibility to meet transit demand. BRT systems can easily be customized to community needs and incorporate state-of-the-art, low-cost technologies that result in more passengers and less congestion.” (https://nbrti.org/planning-and-construction/)

olyaryletherketones (PAEKs) are a family of high-performance thermoplastics originally developed in the 1960s by DuPont for the Apollo space program. Since this creation, one-such PAEK — polyetherketoneketone (PEKK) — has been widely used in the aerospace and defense industries. PEKK’s outstanding high temperature performance, chemical resistance and flame, smoke and toxicity (FST) profile make it a perfect candidate for multiple applications within the transportation industry.

he International Association of Plastics Distribution (IAPD), the international trade association comprised of companies engaged in the distribution and manufacturing of performance plastics, held its premier annual event August 16-19, 2021 at the OMNI Louisville Hotel in Louisville, KY, USA. Full convention and one-day delegates participated in educational sessions from renowned keynote speakers as well as industry experts and connected at exciting networking gatherings.

In addition to the numerous learning opportunities, delegates experienced new and creative networking opportunities, from social hours to receptions to a non-competitive 5K run/walk.

The IAPD connecX tradeshow debuted on Thursday. It featured socially distanced booths with meeting areas and the ability to set up appointments prior to the event with an all-new appointment-setting program.

The convention wrapped up with a lively closing party at Sports and Social Club, featuring a live band that performed something for everyone, from country to metal. Attendees enjoyed playing games such as bowling, air hockey and more.

Save the date: The 66th Annual IAPD Convention will be held September 12-25, 2022 at the JW Marriott Tampa Water Street in Tampa, FL, USA. We look forward to seeing you there!

to our

at SPORTS & SOCIAL CLUB

DeAngelo

DeAngelo will be based near Chicago, IL, USA and will cover a region spanning 16 states including Alaska, Iowa, Idaho, Illinois, Indiana, Michigan, Minnesota, Missouri, Montana, North Dakota, Nebraska, Oregon, South Dakota, Washington, Wisconsin and Wyoming. He will report to Gary Dennis, North American sales manager – Fluoropolymers.

DeAngelo received his degree in chemical engineering from Pennsylvania State University in 2020 and has previously worked as a sales and marketing engineer while also working on technical studies in Arkema’s King of Prussia, PA, USA laboratories.

Porz

Massara

Corporate Profiles

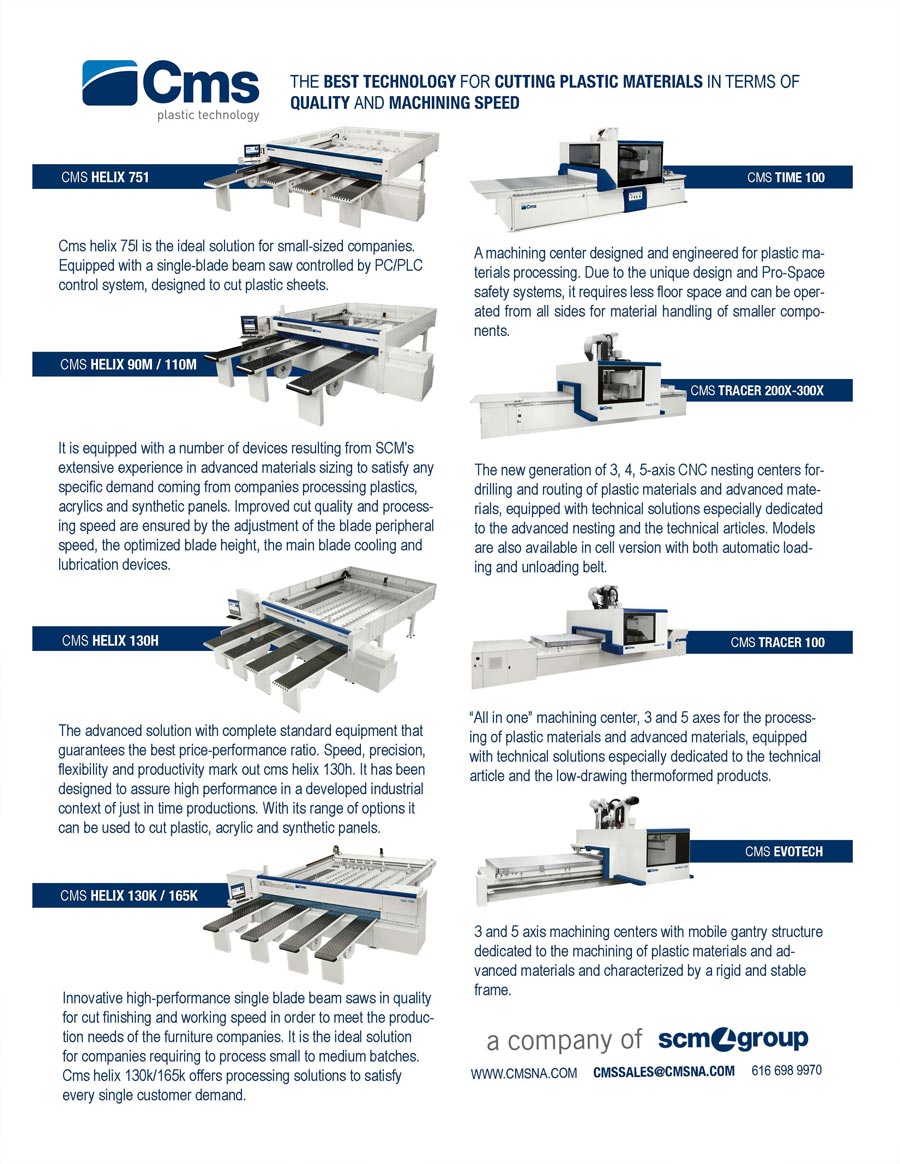

The best technology for cutting plastics

MS SpA was founded in 1969. C.M.S. SpA is the parent company of CMS North America, a brand that brings together five divisions with a worldwide sales and customer service network. Located in Grand Rapids, MI, USA, it is dedicated to the sales, support and service of its customers, their CMS machines, staff training and long-term interests for the efficient usage of technology and continuing communication of its technological developments. CMS’s consistency in excellent price-to-performance ratios, production volumes and exclusive solutions, along with a variety of models, all serve to satisfy a wide array of production requirements. CMS solutions come from experience gained in leading-edge technological sectors and feature state-of-the-art machine tools specially designed for machining advanced materials. CMS has a long standing and renowned specialization in the production of multiaxis CNC machining centers, thermoforming machines, and waterjet cutting systems. The firm has more than 30 years of experience in the manufacturing of advanced machines and decades of successful growth in aerospace, automotive, marine, wind power, eyewear, building, mechanicals, molds, prototypes, plastics, stone and glass processing. CMS’s unprecedented ingenuity extends to patented designs and manufacturing for its own electro spindle with the high torque and speed resulting in top-rank performance in terms of acceleration, speed, and accuracy.

geared towards excellence

olymer Industries has more than 45 years of experience in performance plastics manufacturing. Polymer Industries is proud the quality standards that formed the foundation of the company are still in place today.

As the business expanded to meet the needs of its customers, the product portfolio expanded also. Polymer Industries has one of the largest product offerings from a single manufacturer, including: Densetec® high density polyethylene (HDPE), polypropylene (PP), high molecular weight polyethylene (HMW), low-density polyethylene (LDPE) and Polyslick® ultra-high molecular weight (UHMW-PE). The mechanical division produces a variety of Mechetec® high performance materials, acetals and extruded nylon.

Capabilities include polyolefin sheet extrusion, ram extrusion, mechanical sheet and rod extrusion, compression molding and fabrication. The company strives to continuously introduce innovative products to meet the needs of customers while staying competitive in an ever-changing marketplace.

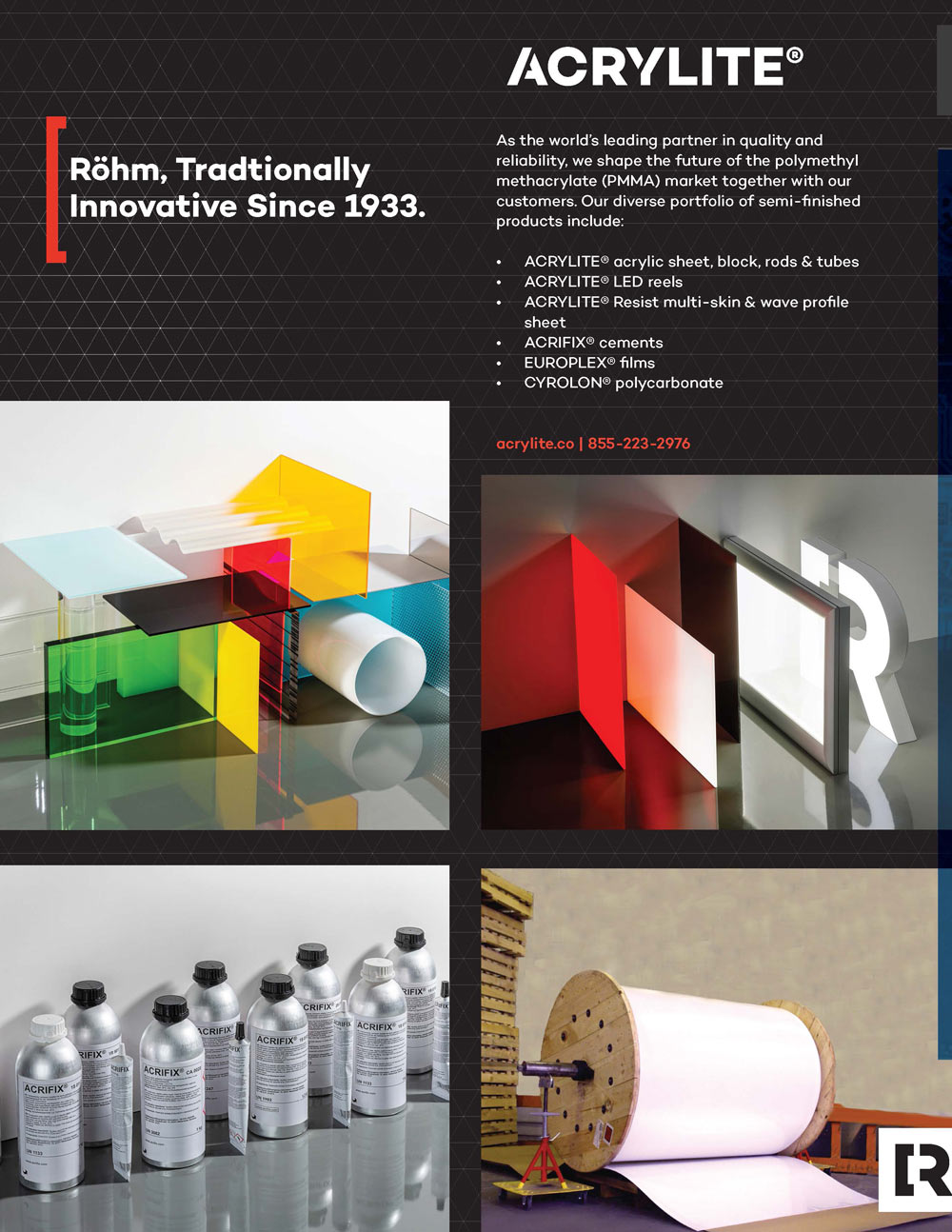

traditionally innovative

öhm is a leading supplier of methacrylate chemicals worldwide. Thanks to their positioning as a global company with 15 production sites on four continents, Röhm is close to their customers and markets. As one of the world’s leading partners in quality and reliability, they are committed to defining the methacrylate markets of tomorrow together with their customers.

With their diverse portfolio of semi-finished ACRYLITE® products, they are one of the world’s leading manufacturers of polymethyl methacrylate (PMMA). Further brands such as CYROLON, EUROPLEX® and ACRIFIX® offer specialist solutions for signage, medical technology, transportation and other industries. A strong partner for industry and trade, the business unit develops innovative products for sustainable applications.

THE PLASTICS EXPERTS

he AGRU success story has been unfolding now for more than seven decades. Founded in 1948 by Alois Gruber Sr., today the company is one of the world‘s most important single-source suppliers for piping systems, semi-finished products, concrete protection liners and lining systems made from engineering plastics.

Seventy years on, AGRU has become a genuine global player. The AGRU Group has plants on three continents and employs more than a thousand staff worldwide. Given that exports currently account for 95 percent of its business, there are AGRU customers all over the globe. Within the industry, AGRU is synonymous with premium quality, customer focus, reliability and professionalism in all areas of plastics engineering. From smartphones to laptops and TV screens, numerous digital devices are now manufactured using AGRU products. Global groups such as SAMSUNG and LG rely on the ultra-pure PURAD piping system made in Bad Hall for their semiconductor production. In the United States, the hidden champion produces large-scale polyethylene pipes with diameters of up to 3.5 m and lengths of up to 600 m. These large pipe strings, weighing up to 1,000 metric tons, are then shipped across the world’s oceans to their deployment locations. One major driver of success in the development of an industrial empire spanning several continents was extensive application engineering expertise, combined with a comprehensive premium plastics engineering portfolio.

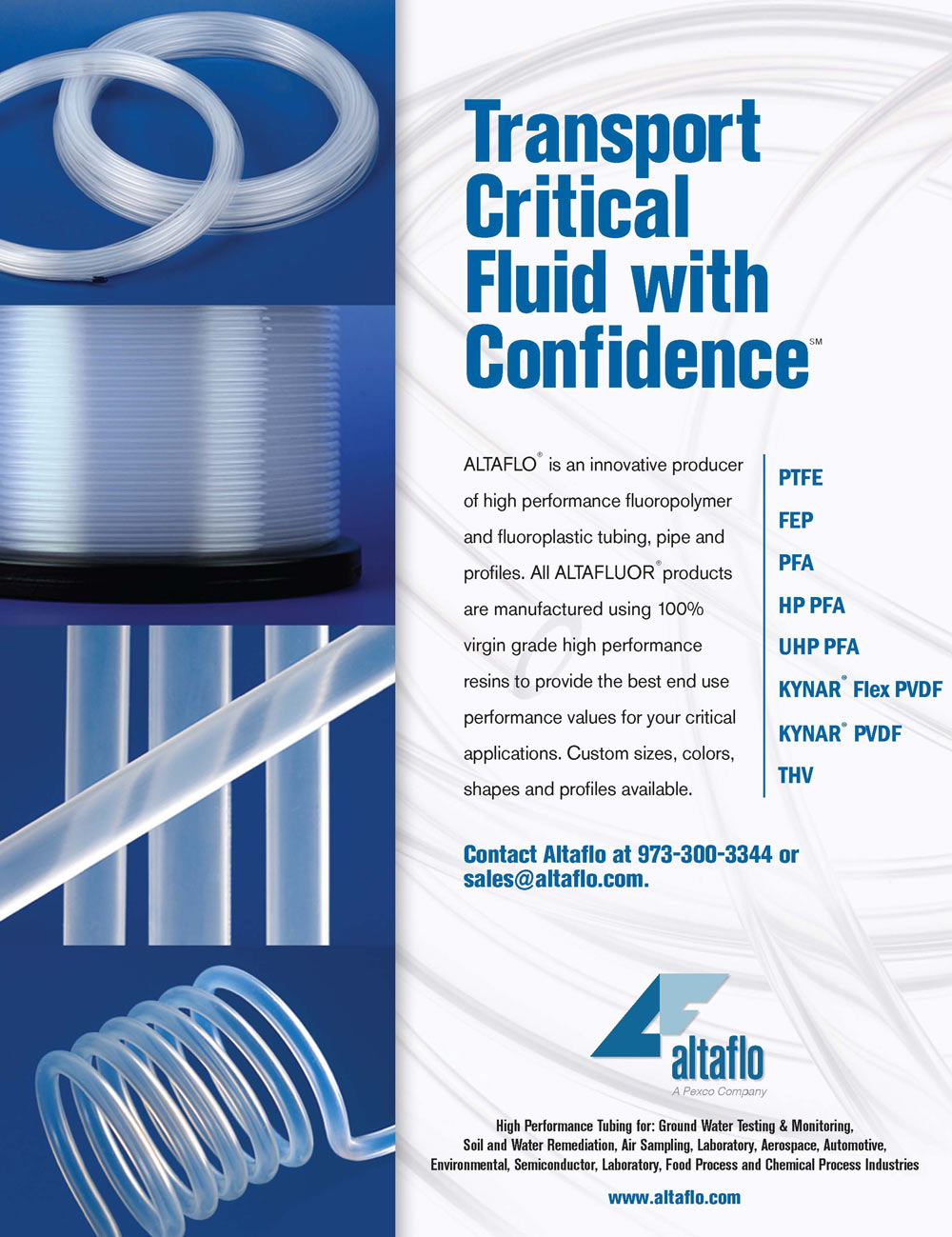

transport critical fluid with confidence

ltaflo, a Pexco Company, is an innovative producer of high performance fluoropolymer and fluoroplastic tubing, pipe and profiles. Since the company’s inception, Altaflo has maintained a consistent focus on the critical requirements of even the most demanding applications.

Their process begins by selecting the highest performance resin grades within each product category. Although there are many resin producers, and various grades offered in each group, Altaflo uses only high molecular weight resin products to ensure optimum performance. These resins provide the highest stress crack resistance, greatest chemical resistance and overall superior performance in their finished products.

Once resin selections have been made, Altaflo adheres to a strict series of process controls to establish maximum efficiency while producing tight tolerance products that meet or exceed industry specifications. Upon request, tighter tolerances or adherence to dimensions other than standard nominal may be provided. In keeping with their commitment to quality, Altaflo has pursued and earned ISO 9000:2015 Certification. They have furthered that commitment by having their tubing tested and certified to the NSF Certifications: 51, 61 and 372.

comprehensive thermoplastic solutions

LASKOLITE is a global leader in manufacturing of engineering thermoplastics, including acrylic, polycarbonate, ABS and PETG sheet, lighting profiles and PMMA polymers. Founded in 1950 by Donald Dunn and family, PLASKOLITE has a reputation for providing the highest quality products in the industry. Their innovative thermoplastic sheet solutions are used in a wide variety of applications, including glazing, safety shields, lighting, signs and point-of-purchase displays.

PLASKOLITE produces superior thermoplastic solutions for customers worldwide. Headquartered in Columbus, OH, USA, PLASKOLITE operates nine manufacturing plants: Columbus, OH; Zanesville, OH, USA; Compton, CA, USA; Olive Branch, MS, USA; Monterrey, Mexico; Memphis, TN, USA; Sheffield, MA, USA; and Grand Saline, TX, USA. Their Linden, NJ, USA facility excels in the development and application of high-performance lighting profiles used by most major LED lighting manufacturers.

Serving plastics distributors through long-lasting relationships, their unique “Run-to-Size” program allows for most sheet products to be ordered in the exact dimensions required, with one of the fastest turnaround times available in the industry.

a global leader in plastics innovation

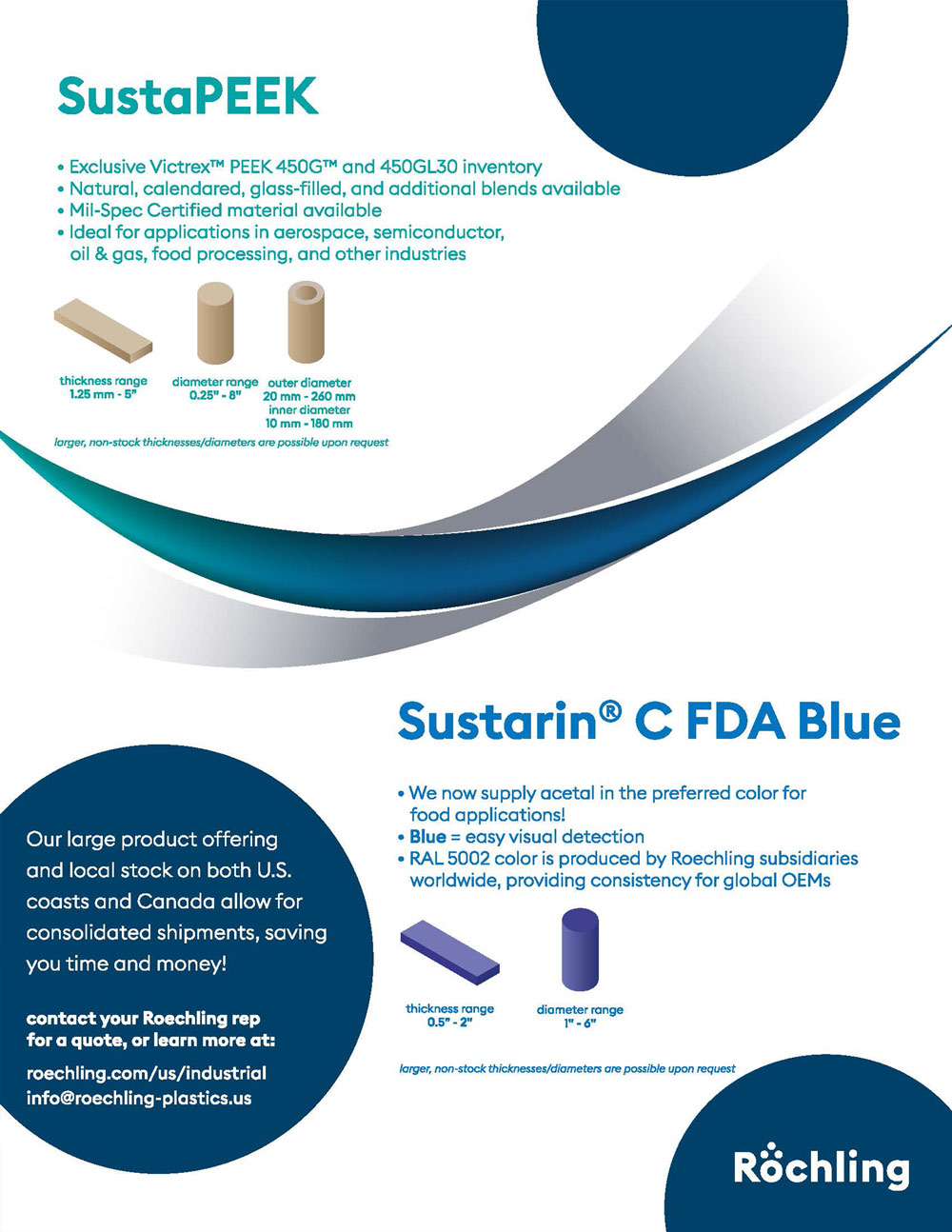

he Röchling Group, made up of industrial, medical and automotive divisions, employs more than 11,000 worldwide at 90 locations in 25 countries. Backed by a global network, Roechling Industrial North America is one of the world’s leading manufacturers of high-quality semi-finished thermoplastics, engineering products and composites. Featuring what they believe to be the most comprehensive product line within the United States, Canada and Mexico, Roechling is committed to developing efficient, innovative and sustainable solutions for their customers.

Through continuous investments and improvements in new manufacturing technologies, Roechling products are used and specified by engineers and cater to a wide range of industries.

leading manufacturer of high-performance ptfe shapes and components

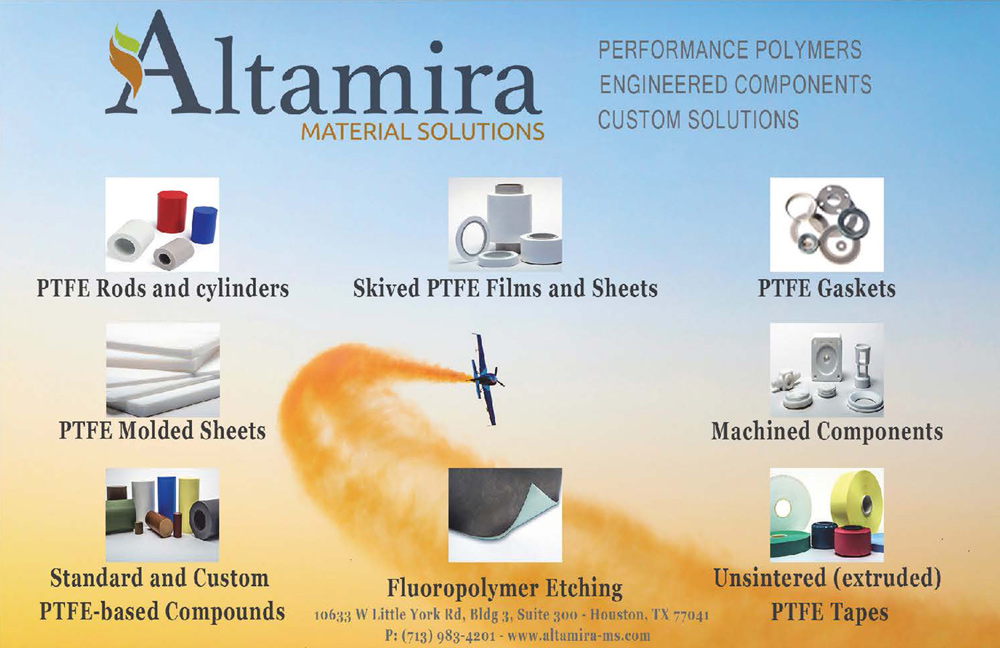

ltamira Material Solutions LP is the leading manufacturer of high-performance polytetrafluoroethylene (PTFE) shapes and components.

They have the technical expertise and capabilities to support standard stock PTFE requirements in a variety of formulations or to work with your technical teams on the development of specialty materials or components for critical applications in semiconductor, aerospace, industrial and oil and gas markets.

sustainability without compromise

hat are Advanced Bio-Circular (ABC) materials?

Arkema’s Advanced Bio-Circular materials are based on amino 11 chemistry. The Group’s flagship Rilsan® polyamide 11 (nylon 11) is first “Advanced” because of its high-performance properties. It offers improvements in weight reduction, flexibility, durability, dimensional stability and corrosion resistance versus standard materials like PA6. The Rilsan® product family includes grades that are tailored for higher temperatures, transparency, conductivity and more.

The “Bio” in Advanced Bio-Circular comes from the bio-based origin of Arkema’s amino 11 chemistry. Specifically, these materials are derived from the castor plant, a sustainable, renewable crop that does not compete with food and does not cause deforestation. Arkema is a leading driver of sustainable castor farming in India.

industry leader in engineering thermoplastic stock shapes

ecognized as a worldwide leader in plastics processing technology and application development, Ensinger has the ability to combine the optimum materials solution with the most suitable manufacturing method, and thus provides the industry with the most innovative and cost-effective engineering solutions available today. Ensinger designs and manufactures semi-finished and finished products tailored exactly to the customer’s individual requirements. Your projects can benefit from Ensinger’s vast knowledge base and many years of experience in finding the best solutions for problems involving engineering thermoplastics materials.

Ensinger offers a broader array of engineering materials than any other plastics processor. From general industrial materials such as polypropylene, polyethylene, acetal and nylon to high performance resins such as TECAPEEK® polyetheretherketone and TECATRON® polyphenylene sulfide, Ensinger has the ability to provide shapes and parts for even the most difficult and challenging applications and environments.

committed to quality and continuous improvements

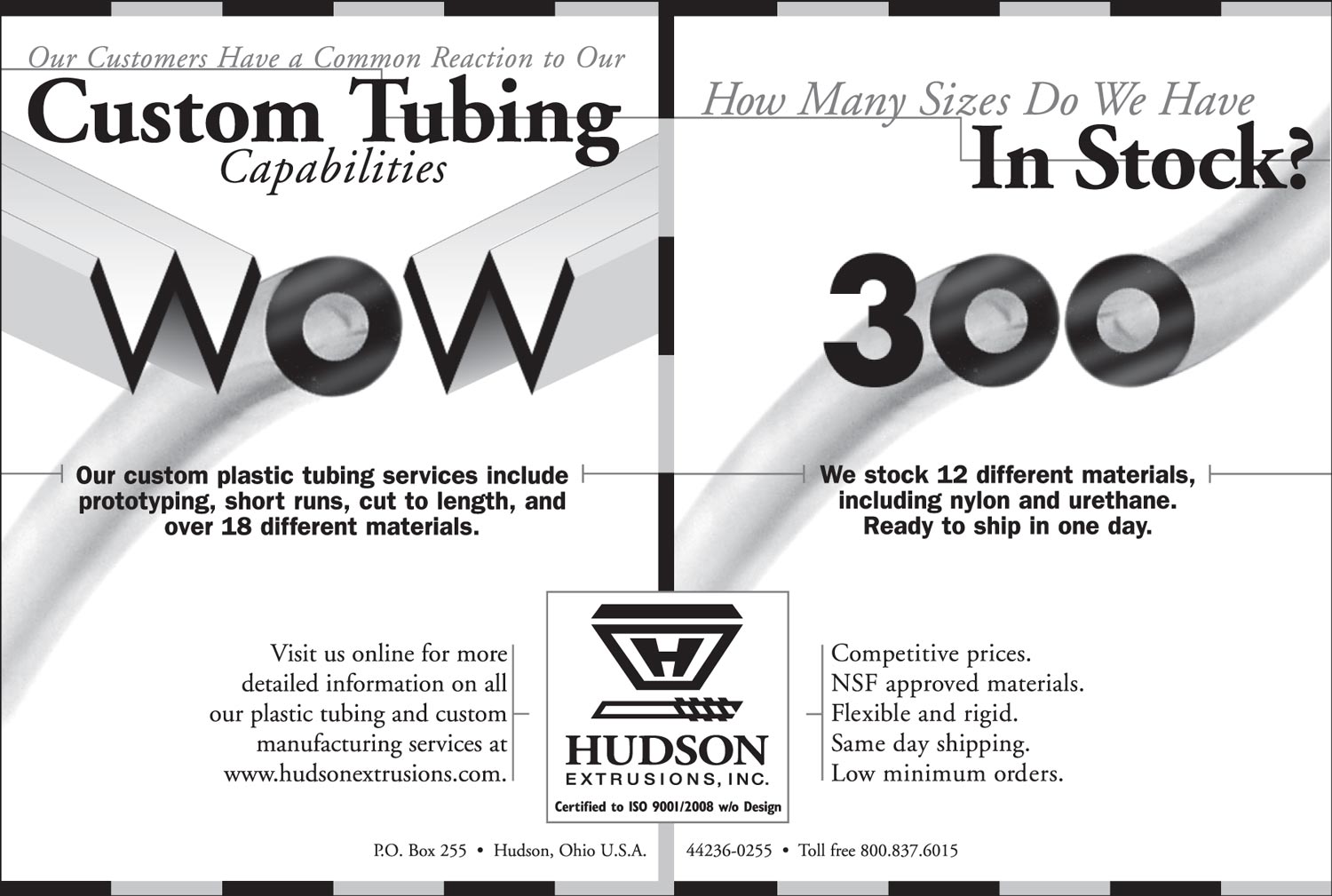

ince their inception over 50 years ago, Hudson Extrusions, Inc. has been dedicated to a singular goal: “Total Customer Satisfaction.” They strive to exceed their customers’ expectations through outstanding customer service, quick turnaround times and producing extruded plastic tubing and profiles of exceptional quality.

Having been family owned and operated since 1956, they value the personal service that has become scarce in today’s technologically advanced environment. Their knowledgeable sales staff has a combined 40+ years of experience in the plastics industry and are ready to help with any questions or inquiries you may have.

Our Innovation. Your Imagination.®

ing Plastic Corporation is a leading manufacturer of quality polymer sheets, slabs and massive shapes — including several products pioneered by the company. Its polymers are made in the United States and sold worldwide through a network of top plastics distributors to customers who fabricate products for the marine industry (King StarBoard® brand), signage, food service, healthcare, architectural, industrial and other markets.

King Plastic manufactures more than 20 products including:

- King StarBoard® — The original marine-grade polymer sheet

- King StarBoard® AS — The anti-skid marine-grade polymer sheet

Gears, machine parts, sprockets, star wheels, wear strips and more.

Gears, machine parts, sprockets, star wheels, wear strips and more.

delivering creative thermoplastic solutions and opportunities for growth

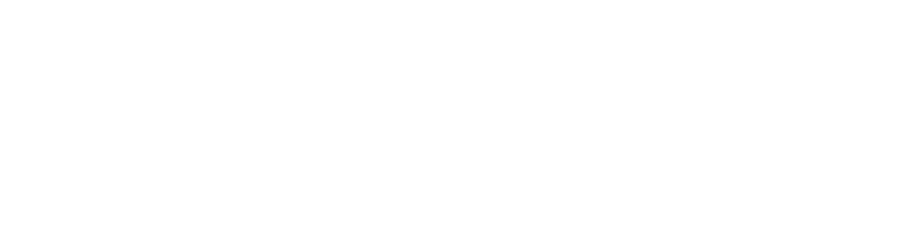

ith more than 55 years of experience, Palram is a market constant that has invented gold standards for polycarbonate and PVC products worldwide. With time-tested resources, proprietary technologies and a rich history of expertise, Palram has become a trusted partner to markets spanning industrial; construction and architecture, safety and security; sign and display and transportation, among others.

Palram is committed to purposeful innovation, drawing inspiration from emerging market trends and customer requirements. Palram’s commitment to technological advancements, equipment investment and product development delivers creative solutions and opportunities for growth.

This unique, coextruded multilayer substrate combines two rigid surfaces of solid, black polymer with a dense black foam PVC core. Lightweight, yet rigid, PALBOARD 3D MAX is 100 percent recyclable, UL94 V-O rated and can withstand harsh chemicals and frequent cleaning cycles. It’s easy to cut and route, can be heat-bent and cold-bent with a v-groove. It offers excellent mechanical strength and screw retention, and its hair-cell texture is scratch and fingerprint resistant.

POLYCARBONATE STRUCTURED SHEETS AND ACCESSORIES I POLYCARBONATE, ACRYLIC and PETG SOLID SHEETS

lazit-Polygal is a pioneer and world leader in the design, development and manufacturing of thermoplastic sheets and profiles. Their products are used worldwide in a broad range of markets and applications. By bridging innovation, quality and service as their cornerstone for success, Plazit-Polygal continually provides products known worldwide for outstanding durability, strength, light transmission, specialty coatings, ease of installation and superior quality. These products provide optimal performance and solutions for walkways, canopies, pool coverings, skylights, roof systems, clerestories commercial and residential greenhouses, interior design, P-O-P displays, signage, window glazing and much more.

Plazit-Polygal has earned an industry-wide reputation for uncompromising quality and innovation and is certified for ISO 9001:2000 and ISO 14001 as well as other international engineering standards such as CSTB (France), BBA (UK), B1 (Germany) and numerous others. With product development and technical support throughout the world, Plazit-Polygal is dedicated to offering world-class customer service, ensuring the company’s ability to maintain their competitive edge on the market.

Rowmark LLC

Findlay, Ohio, USA

one-stop shop for plastic sheet extrusion

owmark LLC is is excited to announce the creation of its custom extruded sheet products webpage at www.rowmarkcustom.com. This webpage was designed to provide easy-to-find, detailed product information on Rowmark’s custom extruded and laminated sheet products and capabilities.

Custom products highlighted on the new website, www.rowmarkcustom.com, include Rowmark’s light diffusing product, Rowmark LD; Rowmark’s high impact acrylic, Rowmark HI Acrylic; Rowmark’s wide range of ABS sheet products; and Rowmark’s thermoplastc elastomer (TPE) products.

Mt. Vernon, Indiana, USA

chemistry that matters™

ABIC’s Functional Forms business offers high quality, engineered thermoplastic sheet and film products across a wide variety of industries, ranging from building and construction, consumer electronics, specialty glazing, aircraft and rail. SABIC’s Functional Forms business has been working to bring its portfolio of leading edge materials to bear in architectural glazing applications for over 40 years. Virtually unbreakable, high optical quality solid and multiwall LEXAN™ (PC) sheet products with highly specialized properties are often a top choice for answering the specific needs of a variety of structures.

Archbald, Pennsylvania; Newcomerstown, Ohio; Findlay, Ohio USA

three manufacturing sites in north america offer a diverse range of products and services to distributors

IMONA AMERICA GROUP consists of three independent manufacturing and sales facilities: SIMONA AMERICA Industries, SIMONA Boltaron and SIMONA PMC.

SIMONA AMERICA Industries specializes in extruded olefin, PVC and fluoropolymer sheet, rod and weld rod for a wide variety of applications, including chemical and corrosion tank manufacturing, semiconductor equipment, marine, outdoor furniture, bathroom partitions, food preparation and orthotics and prosthetics.

Primary materials produced by SIMONA AMERICA Industries include PE, PP, PVC, CPVC, PVDF, ECTFE and PFA. Featured products include:

- BOATBOARD® marine grade HDPE

- Polygrain® woodgrain HDPE

- Polytone® multi-layer color HDPE

- CRP-1® FM 4910 PVC

- SIMOGLAS™ clear PVC

Burr Ridge, Illinois, USA

the plastic welding experts

egener Welding, LLC is an international supplier of high-quality welding, processing and testing equipment for thermoplastic materials. Their mission is not only to offer a wide range of quality products, but to ensure that their customers have access to customized solutions, expert advice, training programs and reliable service and support. A dedicated team of knowledgeable personnel are available to aid in defining the proper equipment for the job at hand as well as finding solutions to any welding problems the customer may have with customized machinery.

In 2006, Wegener Welding, LLC emerged as a new entity out of what was formerly known to the industry as Wegener North America, Inc., which had served the market with the Wegener range of primarily sheet-related thermoplastic welding and fabrication products since the early 1980s. The product lines of their partners Wegener International GmbH, Hürner Schweisstechnik GmbH and Buckleys (UVRAL) Ltd. form a comprehensive source of plastic welding and testing equipment unique to the industry.